Tetrahydrofuran-induced gold nanorod controllable assembly and preparation method thereof

A technology of gold nanorods and tetrahydrofuran, applied in the field of application, can solve the problems of inability to realize the adjustment of optical characteristics, uncontrollable particle distance, low assembly yield, etc., and achieve the effect of short assembly time, low cost and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

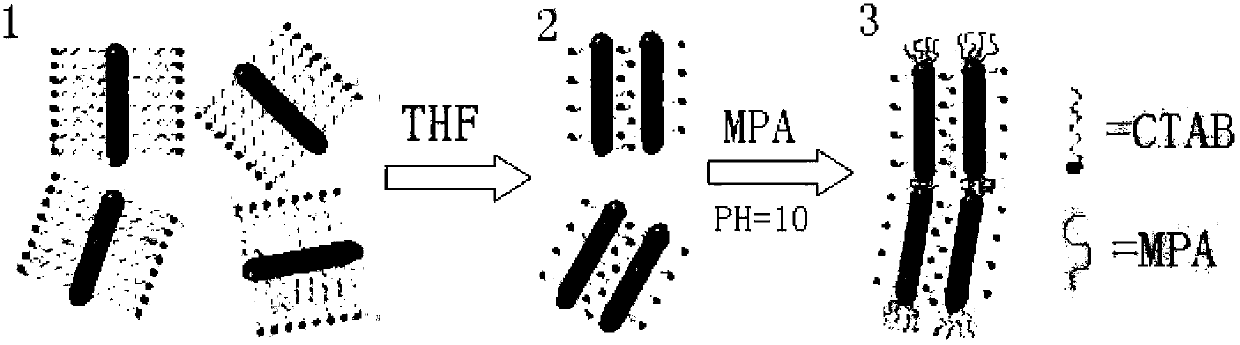

Method used

Image

Examples

Embodiment 1

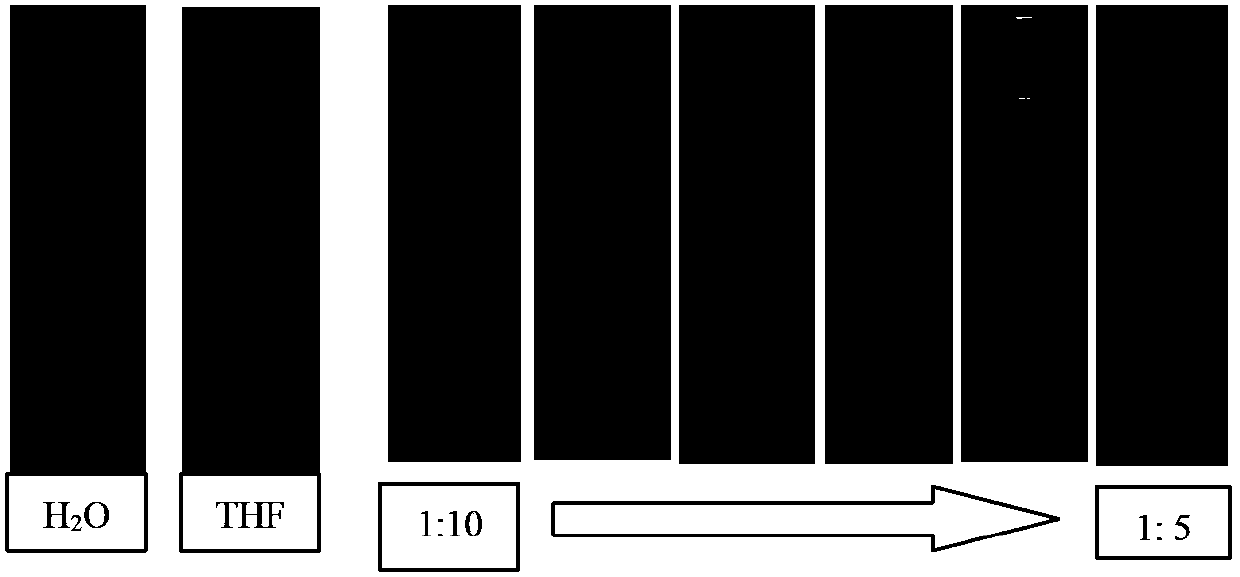

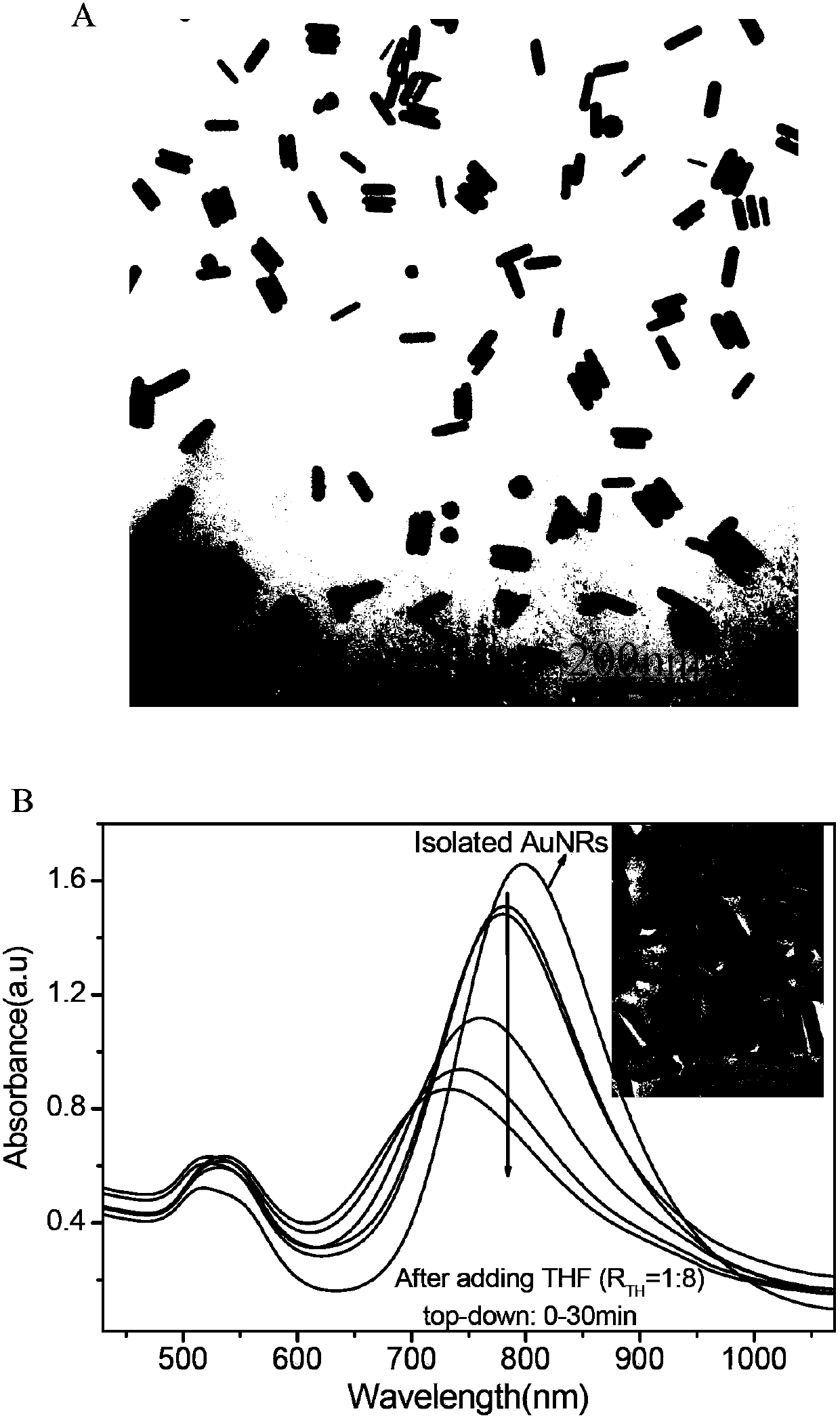

[0033] 28-30°C, add 375 μL of tetrahydrofuran to 3 mL of fresh gold nanorod solution (the concentration of gold nanorods is 0.0075 mg / mL, tetrahydrofuran: water = 1:8, v / v), mix well, and let stand After 1 hour, centrifuge, remove the supernatant solution of the centrifuge tube, and obtain the side-by-side assembly sample. The color, transmission electron microscope picture and absorption spectrum of the sample before centrifugation are as follows: figure 2 (e), image 3 As shown in (A) and (B), it can be seen that most of the obtained samples have been assembled side by side (dimer, trimer).

Embodiment 2

[0035] 28-30°C, add 386 μL of tetrahydrofuran to 3 mL of fresh gold nanorod solution (the concentration of gold nanorods is 0.0075 mg / mL, tetrahydrofuran: water = 1:7, v / v), mix well, and let stand After 50 minutes, centrifuge, remove the supernatant solution of the centrifuge tube, and obtain the side-by-side assembly sample.

Embodiment 3

[0037] 28-30°C, add 500 μL of tetrahydrofuran to 3 mL of fresh gold nanorod solution (the concentration of gold nanorods is 0.0075 mg / mL, tetrahydrofuran: water = 1:6, v / v), mix well, and let stand After 40 minutes, centrifuge, remove the supernatant solution of the centrifuge tube, and obtain the side-by-side assembly sample. The color, transmission electron microscope picture and absorption spectrum of the sample before centrifugation are as follows: figure 2 (g), Figure 4 (A) and (B) shown. It can be seen that most of the obtained samples have been assembled side by side (multimers).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com