Horizontal centrifugal equipment for separating pectins

A centrifugal equipment and pectin technology, applied in the field of food manufacturing, can solve the problems of poor separation effect of pectin and pomace, and achieve the effects of long residence time, saving capital construction cost and good separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

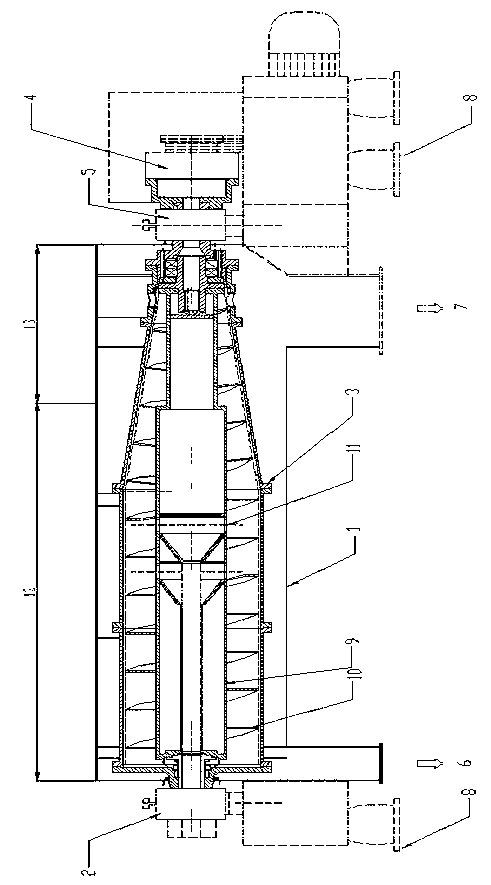

[0010] as attached figure 1 As shown, a horizontal centrifugal equipment for pectin separation, its basic structure includes a casing 1, a feed end bearing seat 2, a drum 3, a differential 4, a differential end bearing seat 5, a liquid phase Outlet 6, solid phase outlet 7 and base 8, etc. The drum 3 is in the casing 1 and is installed on the machine base 8, the feed end bearing seat 2 is installed on the left side of the drum 3, the differential 4 and the differential end bearing seat 2 are installed on the right side of the drum 4 side. The differential end bearing seat 5 is fixed on the machine base 8 and supports the differential gear 4 which is connected to the right side of the drum 3 .

[0011] The drum 3 is divided into a settling zone 12 and a drying zone 13 from left to right in the axial direction. A high-efficiency screw pusher is arranged in the inner cavity of the rotating drum 3. The screw pusher includes a main shaft 9 and a screw pushing piece 10. The main s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com