Integrated water purification device and water purification method

A water purification device and water channel technology, applied in the field of water purification, can solve the problems of easy blockage of the filter head and filter, weak anti-risk ability, easy hardening of the filter material, etc., and achieve the effect of improving cleanliness, reducing cost, and saving land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

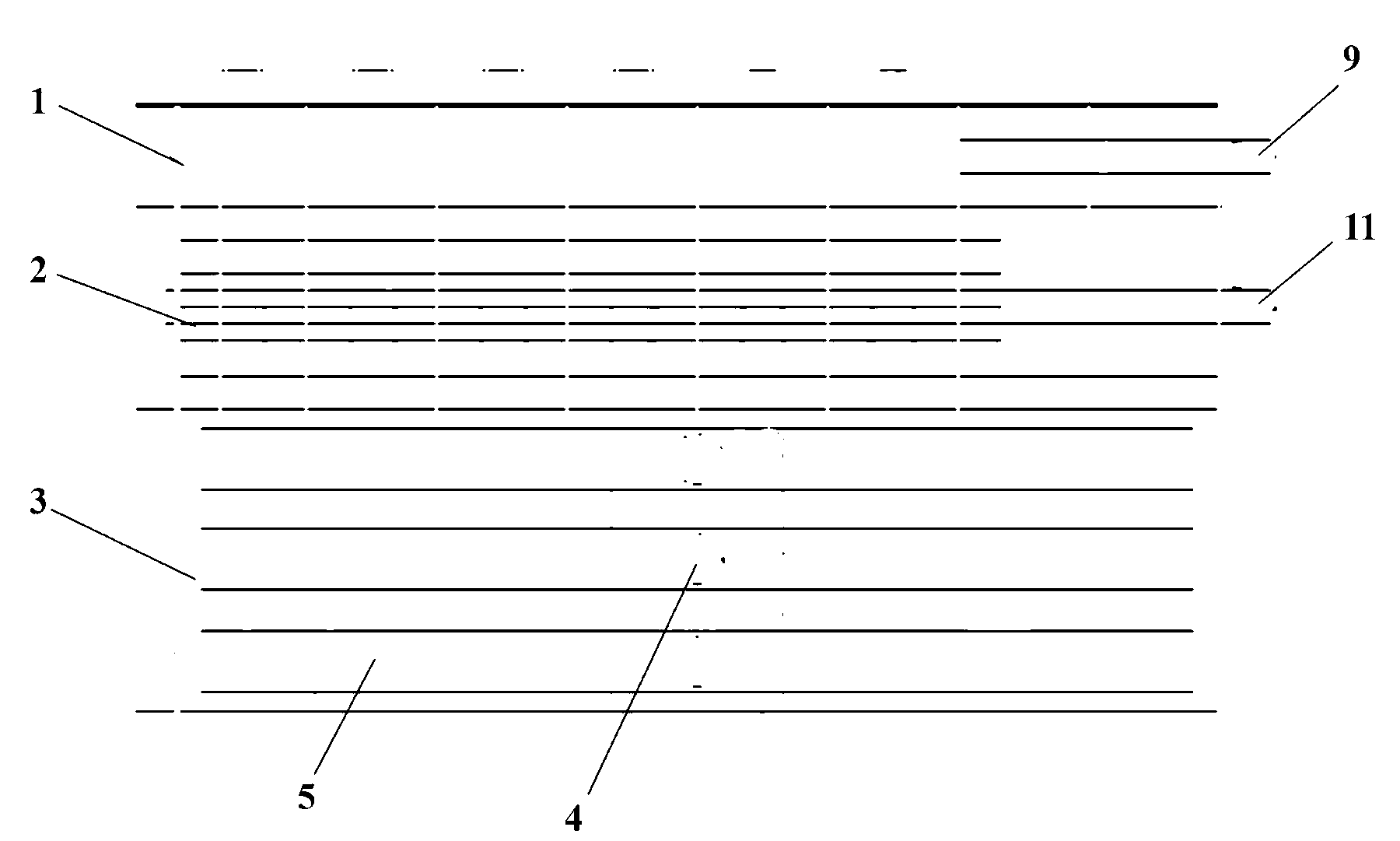

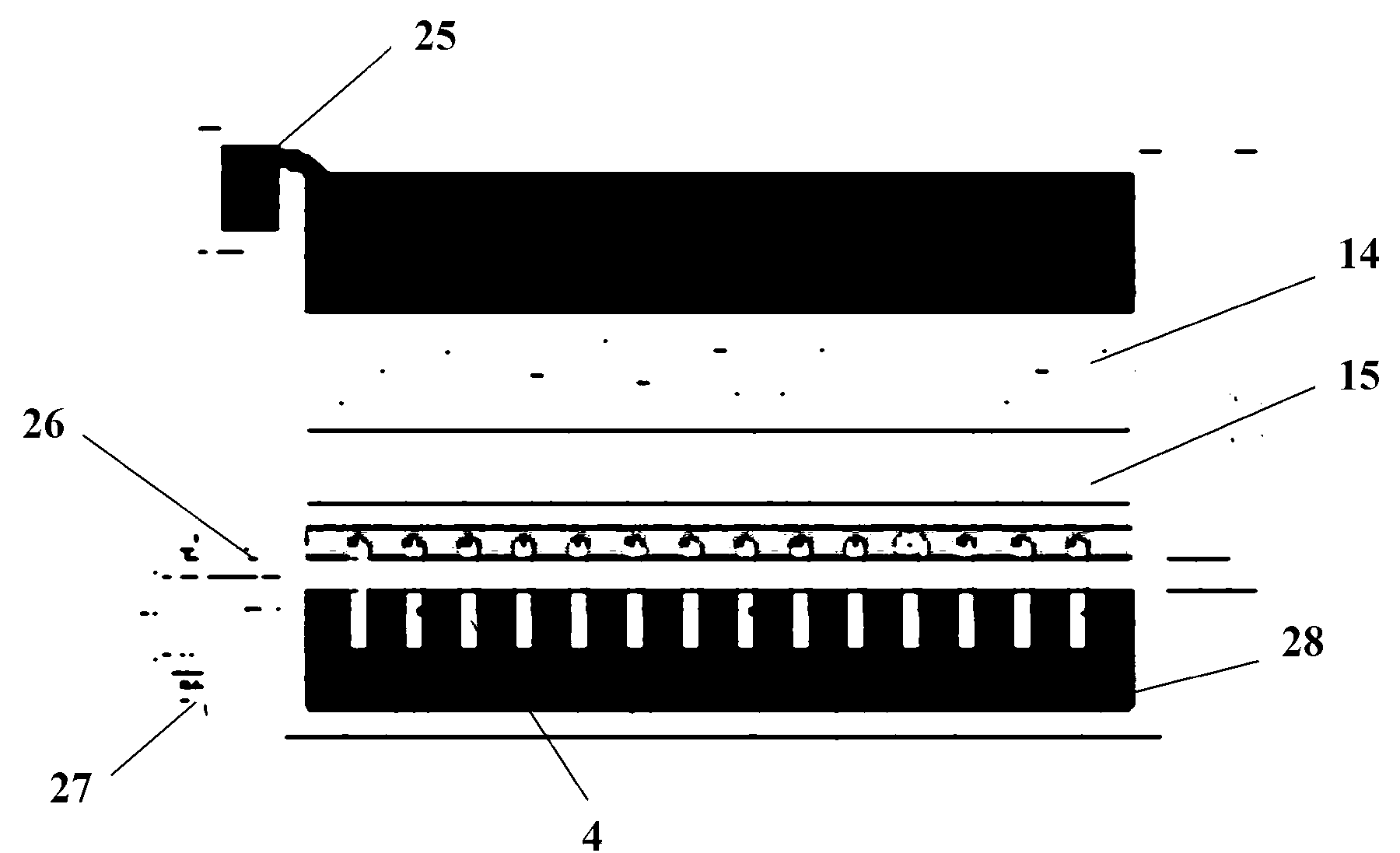

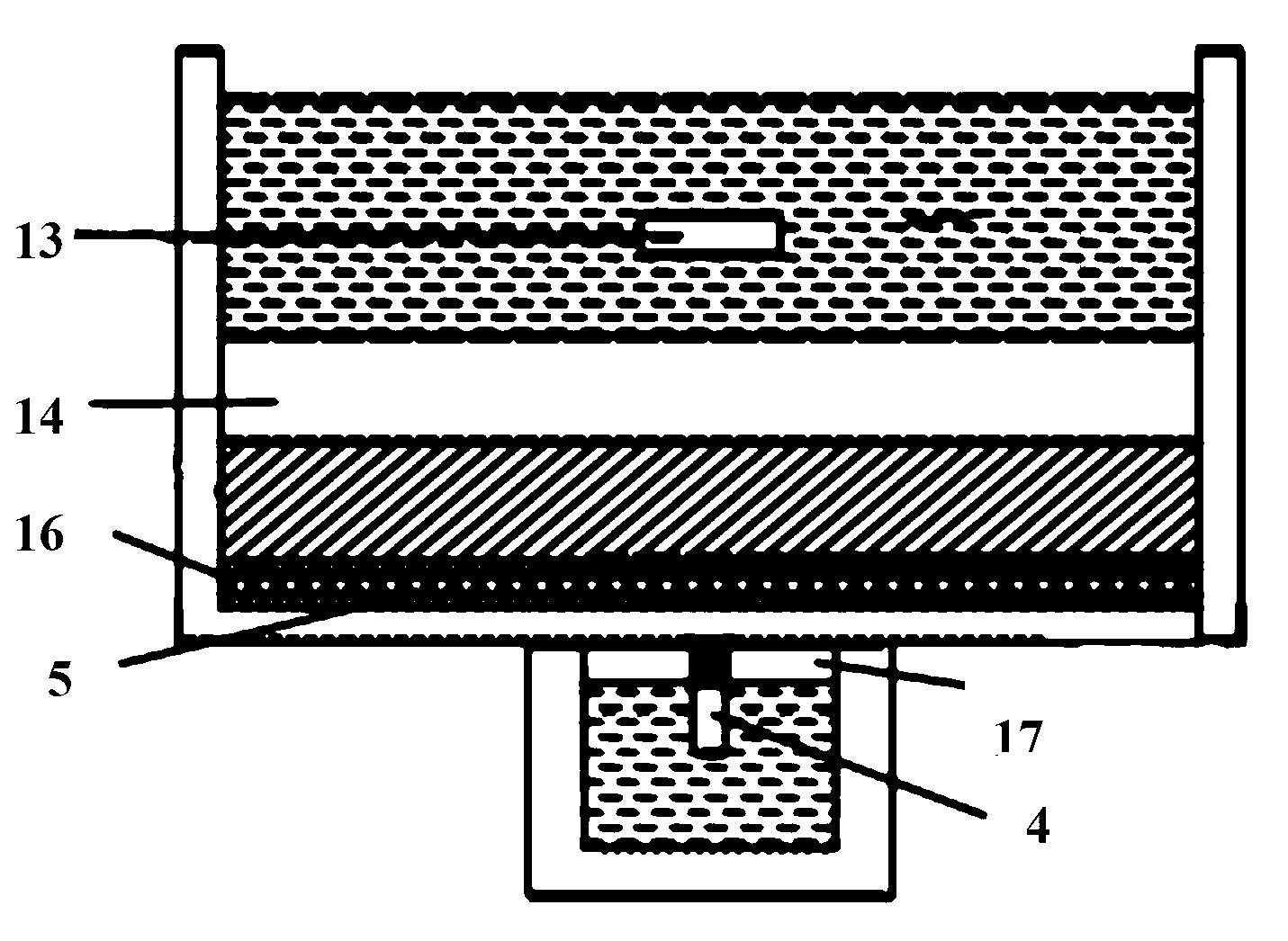

[0033] Embodiment 1 A kind of integrated water purifier (according to 12.5m 3 / h water output is designed, the test flow is 12.5 ~ 15m 3 / h), see figure 1 , figure 2 , including a flocculation tank 1, an inclined plate sedimentation tank 2, and a non-overflow double-layer filter material filter tank 3 connected in series, and the non-overflow double-layer filter material filter tank includes a filter material layer and a supporting layer in sequence from top to bottom 16. Water distribution and gas distribution components, collection and distribution channels 23; the collection and distribution channels 23 are longitudinally arranged along the middle of the filter; the water and gas distribution components include 5 rows of water collecting pipes arranged horizontally and 4 rows of vertical pipes arranged vertically, and The upper ends of the pipes in the vertical pipe rows pass through the filter plates and are respectively connected to the water collection pipes 5 in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com