Intelligent floor wiping machine

A floor mopping machine, intelligent technology, applied in cleaning carpets, cleaning floors, machine parts, etc., can solve the problems of unsatisfactory cleaning effect, unsatisfactory sewage recycling effect, etc., to reduce weight and prolong the time of single work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

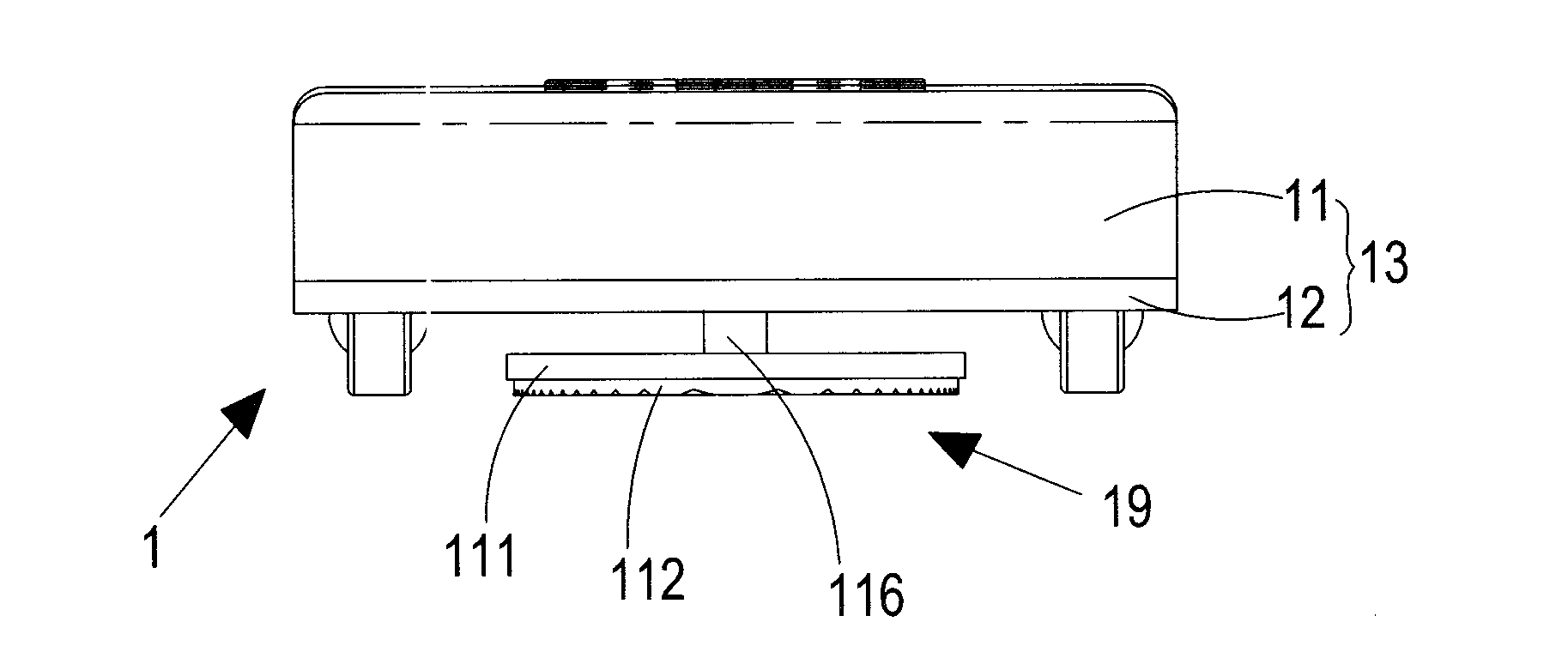

[0035] Such as Figure 4 , 5 As shown, the mopping machine main body 1 includes a housing 13 composed of an upper cover 11 and a lower bottom plate 12. A rechargeable battery 10 is installed inside the housing 13. The upper cover 11 is provided with a second connection for charging the rechargeable battery 10. Electrical terminal 121, the top of the upper cover 11 is provided with a receiving unit 124 for receiving signals transmitted by the transmitting unit 23. This receiving unit 124 can be a common omnidirectional or directional receiver, and the number can be set as one or more as required. The lower bottom plate 12 is provided with several moving wheel assemblies 14 that can drive the entire mopping machine main body 1 to move on the ground to be cleaned, and the moving wheel assembly 14 is equipped with a first drive unit that drives it to move. In this embodiment, the mobile wheel assembly 14 includes four wheel bodies in total, two of which are front wheels 15, and t...

Embodiment 2

[0038] Such as Figure 7 , 8 As shown, the mopping machine main body 1' includes a housing 13' composed of an upper cover 11' and a lower bottom plate 12'. A rechargeable battery 10' is installed inside the housing 13', and the upper cover 11' is provided with a battery for charging The second electrical connection terminal 121' for charging the battery 10', the top of the upper cover 11' is provided with a receiving unit 124' for receiving signals transmitted by the transmitting unit 23, this receiving unit 124' can be a common omnidirectional or directional receiver, The quantity can be set as one or more as required. The lower base plate 12' is provided with several moving wheel assemblies 14' that can drive the whole mopping machine main body 1' to move on the ground to be cleaned, and the moving wheel assembly 14' is equipped with a first drive unit that drives it to move. In this embodiment, the moving wheel assembly 14' includes a total of four wheel bodies, two of wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com