Non-contact power supply device

A non-contact power supply and non-contact technology, which is applied in the direction of electrical components, electrical components, electromagnetic wave systems, etc., can solve problems such as errors, reduction in transmission efficiency of non-contact power supply, and inability to fully improve the transmission efficiency of non-contact power supply, so as to improve transmission efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

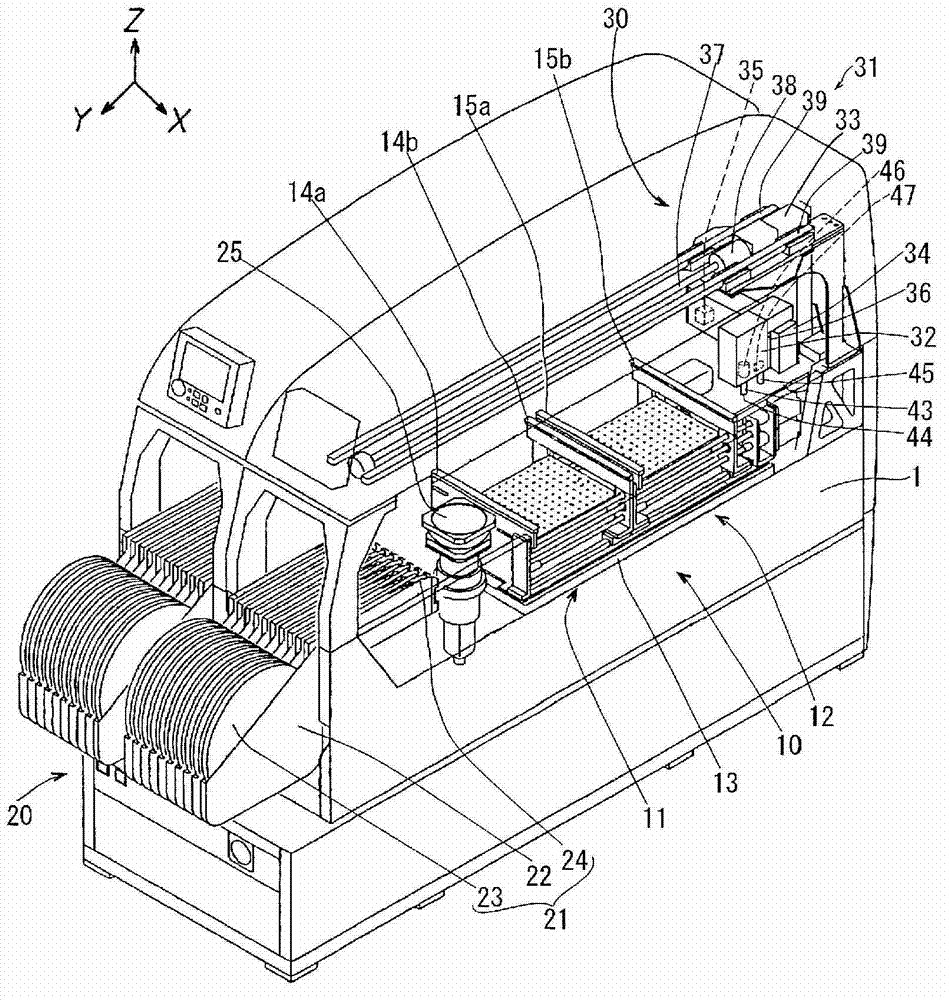

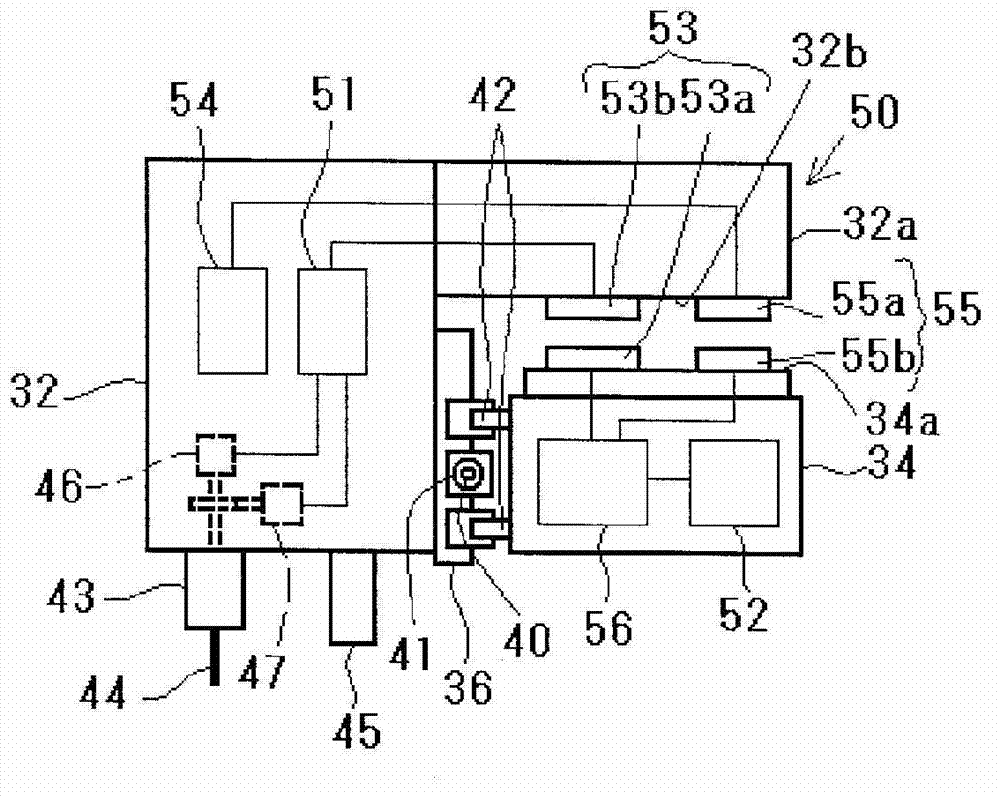

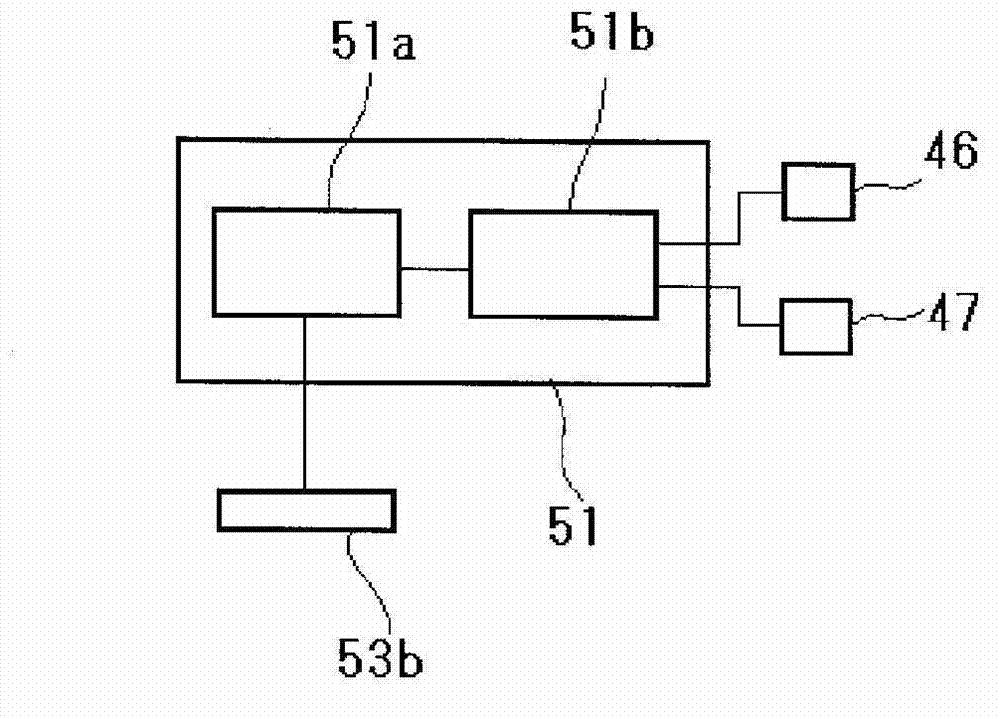

[0022] Hereinafter, the case where the embodiment of the contactless power supply device of the present invention is applied to a component mounting device will be described with reference to the drawings. Such as figure 1 As shown, the component mounting device is roughly composed of a board transfer device 10 , a component supply device 20 and a component transfer device 30 . In addition, in figure 1 Herein, the conveyance direction of the substrate is defined as the X-axis direction, the horizontal direction perpendicular to the X-axis direction is defined as the Y-axis direction, and the vertical direction perpendicular to the Y-axis direction is defined as the Z-axis direction.

[0023] The substrate transfer device 10 is a so-called double-conveyor type substrate transfer device in which a first transfer device 11 and a second transfer device 12 for transferring a substrate in the X-axis direction are arranged in two rows. The first conveying device 11 and the second c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com