Motor performance testing device with high-strength equivalent weight support

A testing device and high-strength technology, which is applied in the direction of motor generator testing, measuring device casing, etc., can solve the problems of waste of testing cost of mounting plate motor, lack of versatility and interchangeability of installation, etc., and achieves simple structure and good heat dissipation effect. , Accurate heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

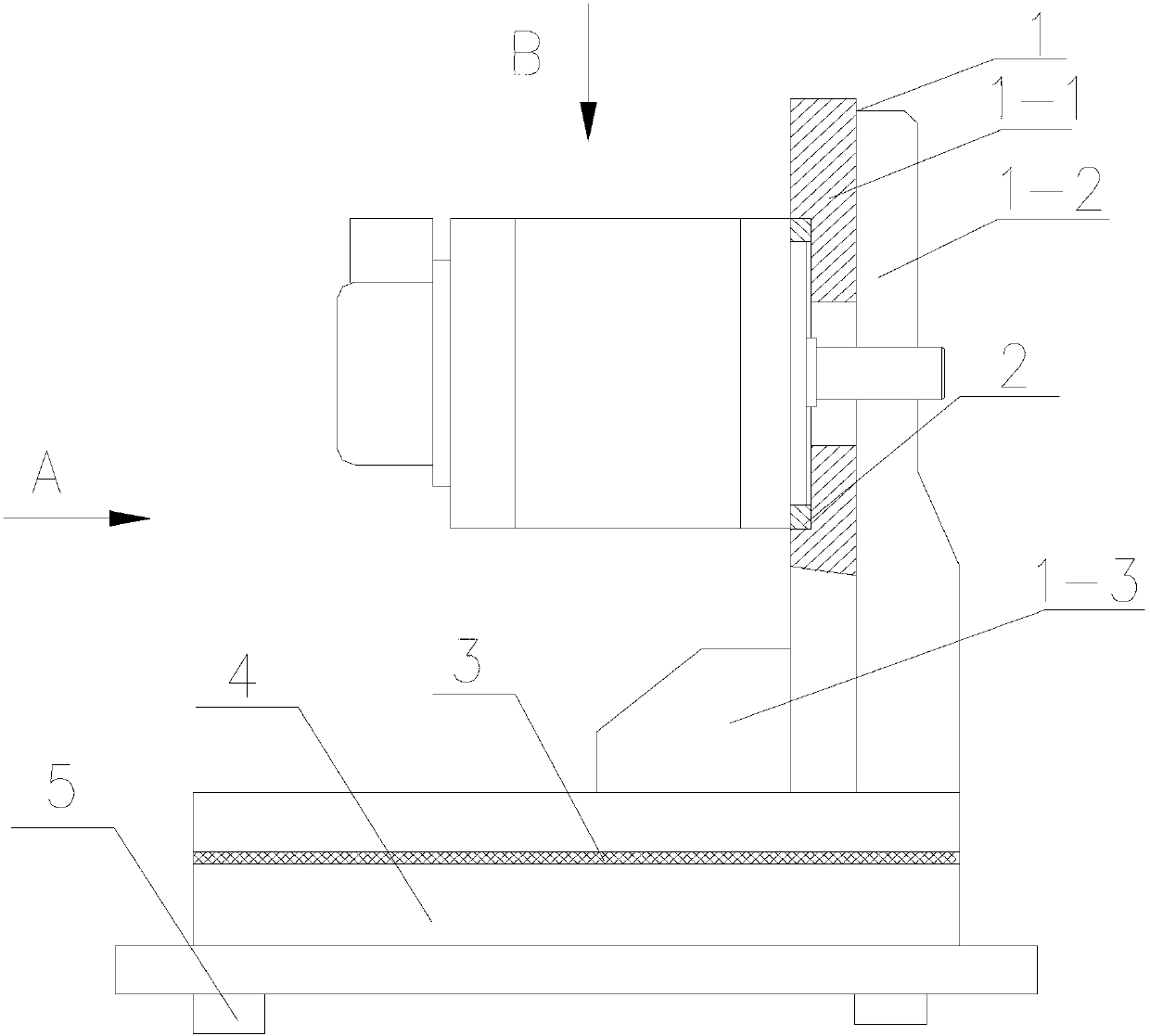

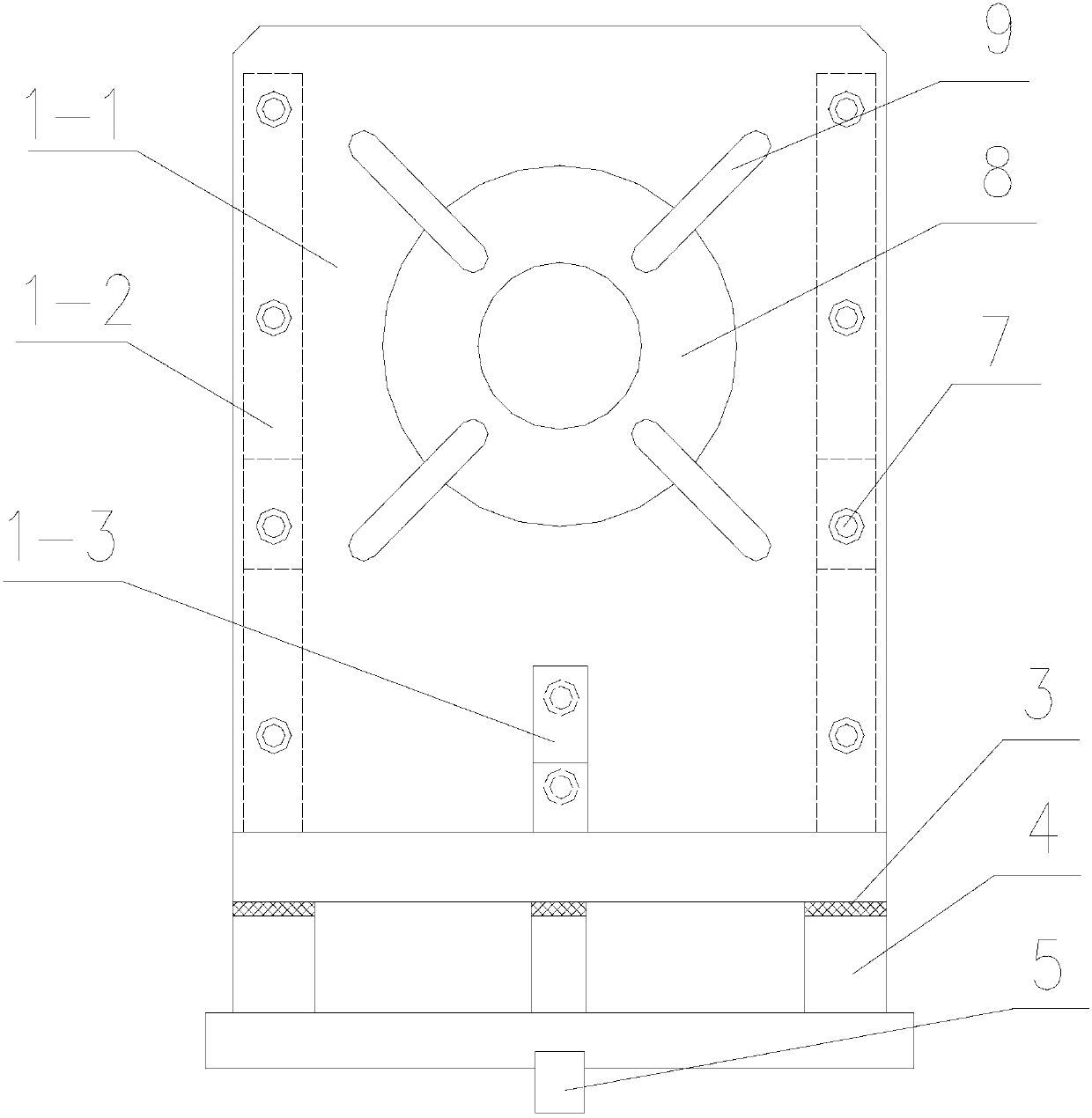

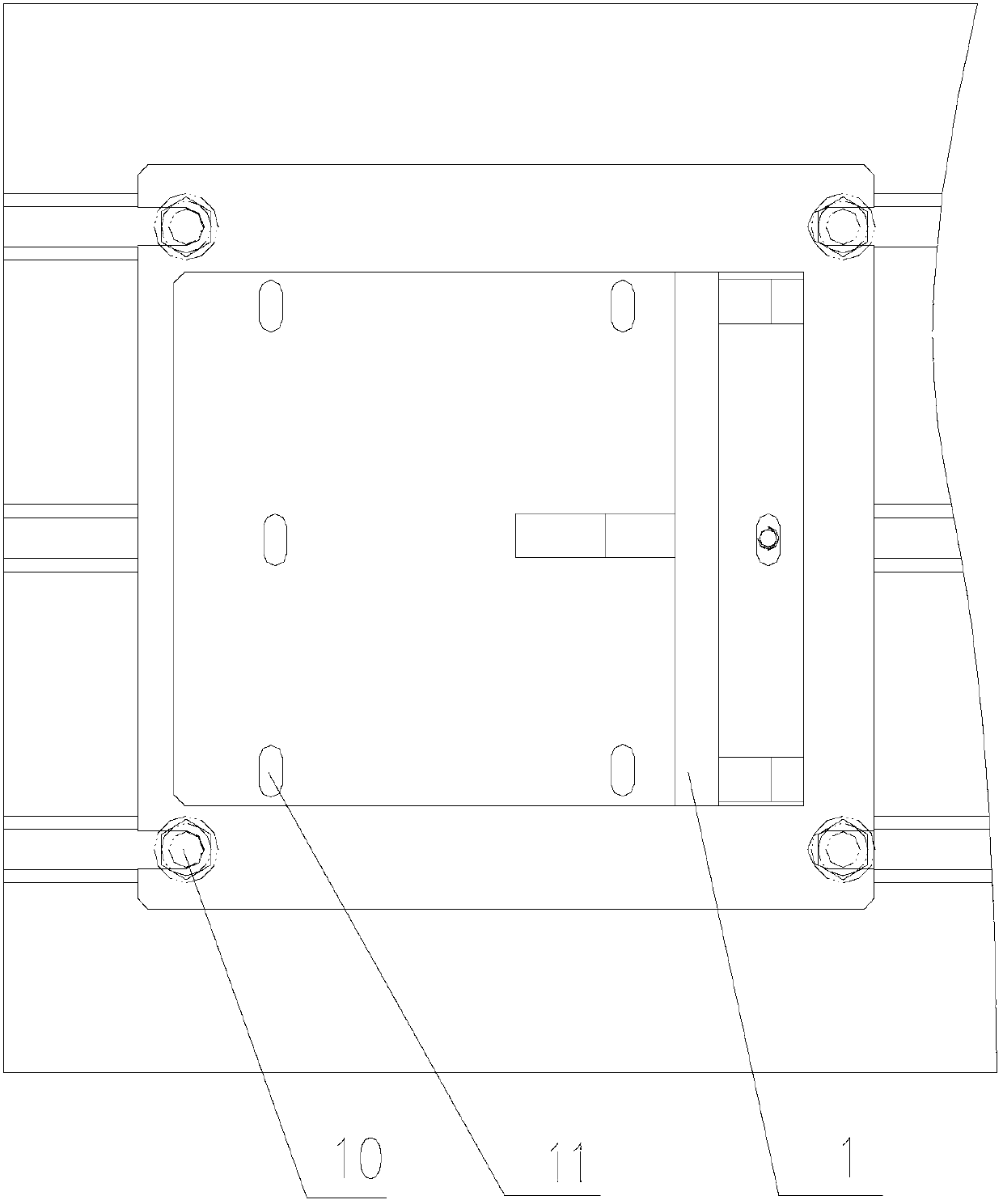

[0028] In this embodiment, a motor performance test device with a high-strength equivalent bracket, such as figure 1 or Figure 4 As shown, it includes an equivalent bracket 1, a bottom plate 4, and a platform 6. The equivalent bracket is set on the platform through the bottom plate. The equivalent bracket has an L-shaped structure and includes a main board and multiple attached boards. Each attached board is fixed to the main board by a bracket bolt 7 Above, a heat shield 3 is also provided between the equivalent support 1 and the bottom plate 4. The size and installation position of the attached board can be set according to actual needs. The size of the equivalent bracket depends on the surface area of the entire bracket and the surface area of the standard bracket; the purpose of setting the heat insulation board is to make the equivalent bracket as an independent heat sink, regardless of the bottom plate And the size of the platform affects the heat dissipation.

[0029...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com