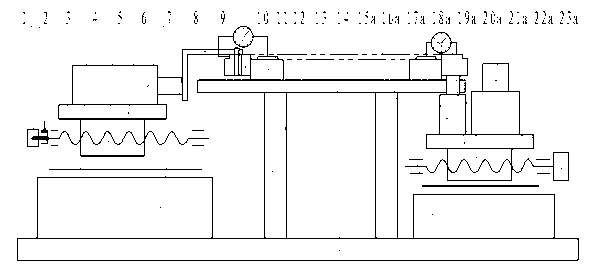

Gap detection device of large slewing bearing

A technology for slewing bearings and detection devices, which is applied to measuring devices, instruments, etc., can solve the problems of large slewing bearings with large diameter and weight, unreliable detection results, and increased accidental errors, so as to avoid artificial visual errors and reduce accidental errors the possibility of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

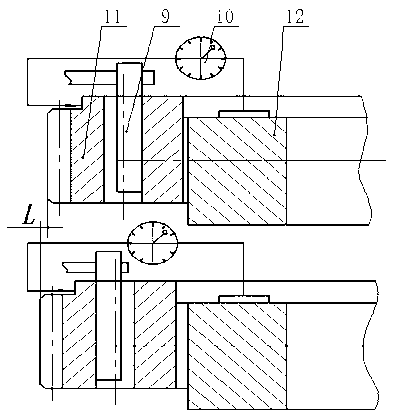

[0016] Example 1: Detection of axial clearance

[0017] When the slewing bearing to be tested is an external gear type, first place the slewing bearing to be tested on the detection workbench 13, and the controller drives the first axial servo motor 23a, the second axial servo motor 23b, and the third axial servo motor. The servo motor 23c rotates at the same time, respectively driving the first centering mechanism 20a, the second centering mechanism 20b, and the third centering mechanism 20c to move in the radial direction simultaneously to complete the centering of the inner ring 12 of the slewing bearing to be tested, and then through the screw platen The clamping mechanism fixes the inner ring 12 of the slewing ring to be tested on the detection workbench 13, and at this time, the outer ring 11 of the slewing ring to be tested naturally sags under the action of its own weight. Fix the fixed end of the axial displacement sensor 17 on the upper surface of the inner ring 12 o...

Embodiment 2

[0019] Embodiment 2: Detection of Radial Clearance

[0020]When the slewing bearing to be tested is an external gear type, first place the slewing bearing to be tested on the detection workbench 13, and the controller drives the first axial servo motor 23a, the second axial servo motor 23b, and the third axial servo motor. The servo motor 23c rotates at the same time, and respectively drives the first centering mechanism 20a, the second centering mechanism 20b, and the third centering mechanism 20c to move simultaneously in the radial direction to complete the centering of the inner ring 12 of the slewing bearing to be tested, and then through the screw platen The clamping mechanism fixes the inner ring 12 of the slewing bearing to be tested on the testing workbench 13 . The radial servo motor 1 is driven by the controller, and when the radial worktable 6 is driven by the radial ball screw 3 and the radial screw nut 5 to move to the detection position on the radial rolling gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com