Cold source temperature control method and device of flue gas waste heat recovery device

A temperature control method and flue gas waste heat technology, which are applied in heat exchange equipment, lighting and heating equipment, and greenhouse gas reduction, etc., can solve problems such as failure to reach set values, wall temperature fluctuations, and system oscillations, and achieve improved control. quality, preventing undershoot or overshoot, improving the effect of large inertia and large hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to facilitate the understanding of the present invention, an embodiment is given in conjunction with the accompanying drawings to further illustrate the present invention.

[0055] Step 1: Parameter collection. The temperature sensor installed in the heat exchanger will measure the temperature of cold water in the heat exchanger, hot water temperature, cold source water temperature in the mixing water tank, heat exchange wall temperature of the heat exchanger, and flue gas temperature. Five parameters are collected;

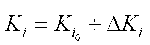

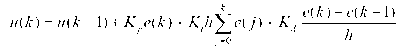

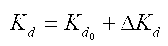

[0056] Step 2: The data unit calculates the temperature error e and the temperature difference change ec based on the parameters collected in step 1, and sends the temperature error e and the temperature difference change ec to the fuzzy controller. The relationship between the temperature difference e and the temperature difference change ec The formula is:

[0057]

[0058] The symbols in the formula have the same meaning as the text.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com