Fast-to-install photovoltaic assembly system of slope roof and installing mode of assembly system

A photovoltaic module and installation method technology, which is applied in the field of light energy, can solve the problems of low installation efficiency and large roof damage, and achieve the effect of novel and unique structure, fast and convenient installation of components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

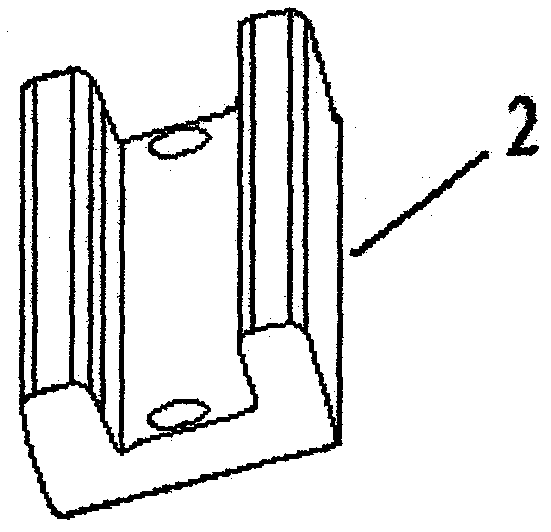

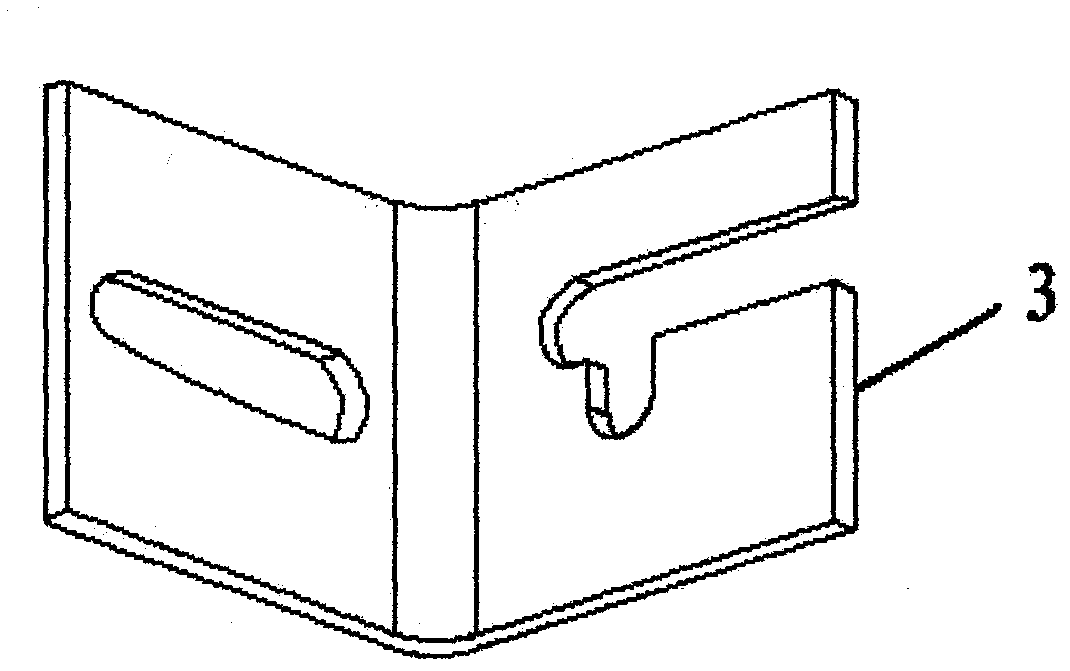

[0031] Combine figure 1 with Figure 5 As shown, the component frame 1 is provided with a first frame slot 4 and a second frame slot 5 with the same structural size along the length direction, which are arranged in parallel and adjacent to each other, for connecting components. The module frame 1 adopts an extrusion molding method, and the long frame and the short frame are made of uniform profiles, such as stainless steel. The component frame 1 is fixed by the connecting piece 2, so that the connected component can become a rigid whole. In addition, the support 3 can also be directly installed and fixed.

[0032] Satisfied functional effects:

[0033] (1) It is convenient to install and fix the connector through two card slots, and realize the simultaneous fixation of left and right and up and down.

[0034] (2) It is convenient to install and fix with the support, and can be supported and fixed at any position of the frame.

[0035] (3) The structural strength is sufficient to sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com