Steel with fusible wrapping layer

A cladding and steel technology, which is applied in construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of increasing the cost of underground obstacles, building construction obstacles, waste of materials, etc., and achieves simple structure, convenient operation, and reduced The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described below in conjunction with accompanying drawing.

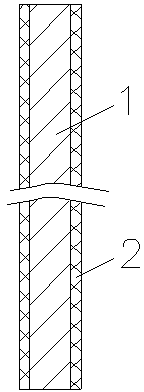

[0018] Such as figure 1 Shown is a steel material with a fusible grip layer according to the present invention, which includes a steel body and a fusible grip layer 2; the fusible grip layer 2 is arranged outside the steel body to tightly wrap the steel material Body; in this embodiment, the steel body is a steel bar; of course, the steel bar body can also be steel pipe, steel strand, section steel; the fusible grip layer 2 is made of epoxy resin or plastic or wax or nylon become.

[0019] Such as figure 2 Shown is a schematic diagram of the application state of a steel material with a fusible grip coating according to the present invention. An anchor hole 4 is arranged in the rock and soil body 3, and the steel material with a fusible grip coating layer of this scheme is set in the anchor hole 4. , and then fill the concrete 5 to achieve the role of supporting the rock and soil mas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com