Energy-saving type vibration exciter for vibratory roller

A vibratory roller and vibration exciter technology, which is applied in the field of construction machinery, can solve the problems affecting the configuration power of the engine, the efficiency of the transmission system and the reliability of the whole machine, the unfavorable vibration starting and stopping of the vibrating machine, and the unstable compaction of the vibrating roller. , to achieve the effect of high promotion and application value, good economic benefits and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

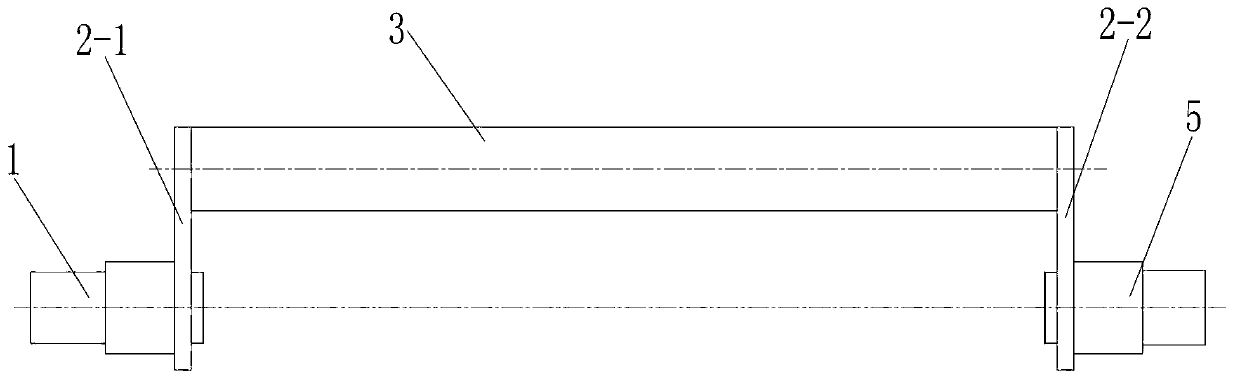

[0030] Such as figure 1 As shown, the present invention includes a vibrator body, and the vibrator body includes a first transmission shaft 1 and a second transmission shaft 5 arranged at intervals, and the first transmission shaft 1 is fixedly connected with a first shaft protruding upward. The connecting crank 2-1, the second transmission shaft 5 is fixedly connected with the second connecting crank 2-2 extending upwards and having the same length as the first connecting crank 2-1, the first connecting crank 2- 1 and the second connecting crank 2-2 are fixedly connected with a fixed bar 3 for generating an exciting force, and the fixed bar 3 is parallel to the first transmission shaft 1 and the second transmission shaft 5 .

[0031] In this embodiment, the first connecting crank 2-1 is welded to the first transmission shaft 1, the second connecting crank 2-2 is welded to the second transmission shaft 5, and the fixed bar 3 One end is welded with the first connecting crank 2...

Embodiment 2

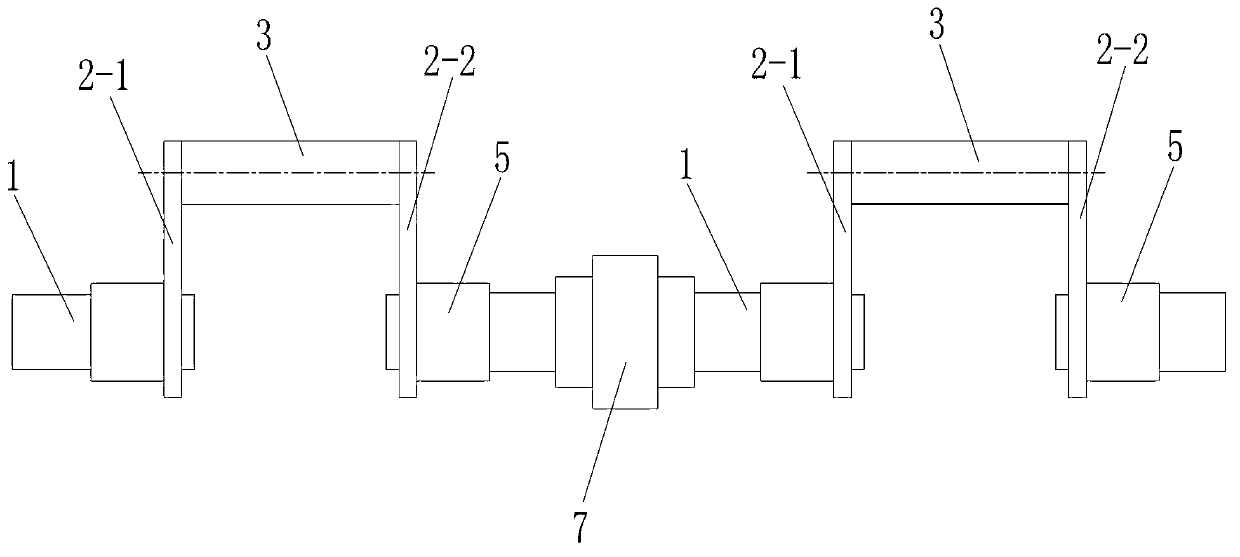

[0034] Such as figure 2 As shown, the difference between this embodiment and Embodiment 1 is that the number of the exciter bodies is two, and the two exciter bodies are connected through a coupling 7 . All the other structures are the same as in Example 1.

[0035] When the exciter is specifically processed and manufactured, the length of the fixed bar 3 is relatively short, and the overall length of the exciter body is relatively short. Two such exciter bodies are required to form an exciter for a vibratory road roller. The working principle and embodiment 1 is the same.

Embodiment 3

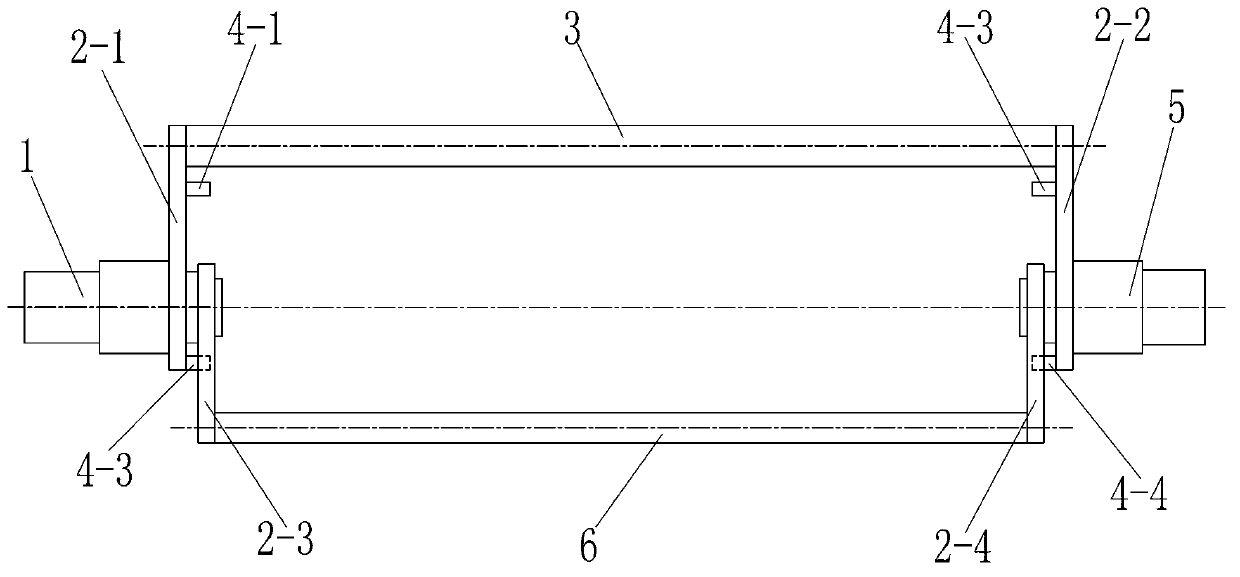

[0037] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that a section of the first transmission shaft 1 located inside the first connecting crank 2-1 is rotatably connected with a third connecting crank 2 protruding downward through a first bearing. -3, a section of the second transmission shaft 5 located inside the third connecting crank 2-3 is rotatably connected to a fourth connecting part extending downwards and having the same length as the third connecting crank 2-3 through a second bearing The crank 2-4, the third connecting crank 2-3 and the fourth connecting crank 2-4 are fixedly connected with a movable bar 6 for cooperating with the fixed bar 3 to adjust the amplitude of the vibratory road roller. The inner side of a connecting crank 2-1 is provided with a first upper stop pin 4-1 above the first transmission shaft 1 and a first lower stop pin 4-2 below the first transmission shaft 1, the The inner side of the second connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com