Raw coal gas guide device of coal pyrolysis furnace

A technology of raw gas and coal pyrolysis, applied in the field of coking ovens, can solve problems such as difficult control of the pressure in the furnace, difficulty in cleaning the gas collecting pipe device, and inability to control the suction of the fan, etc., and achieve the effect of uniform pressure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

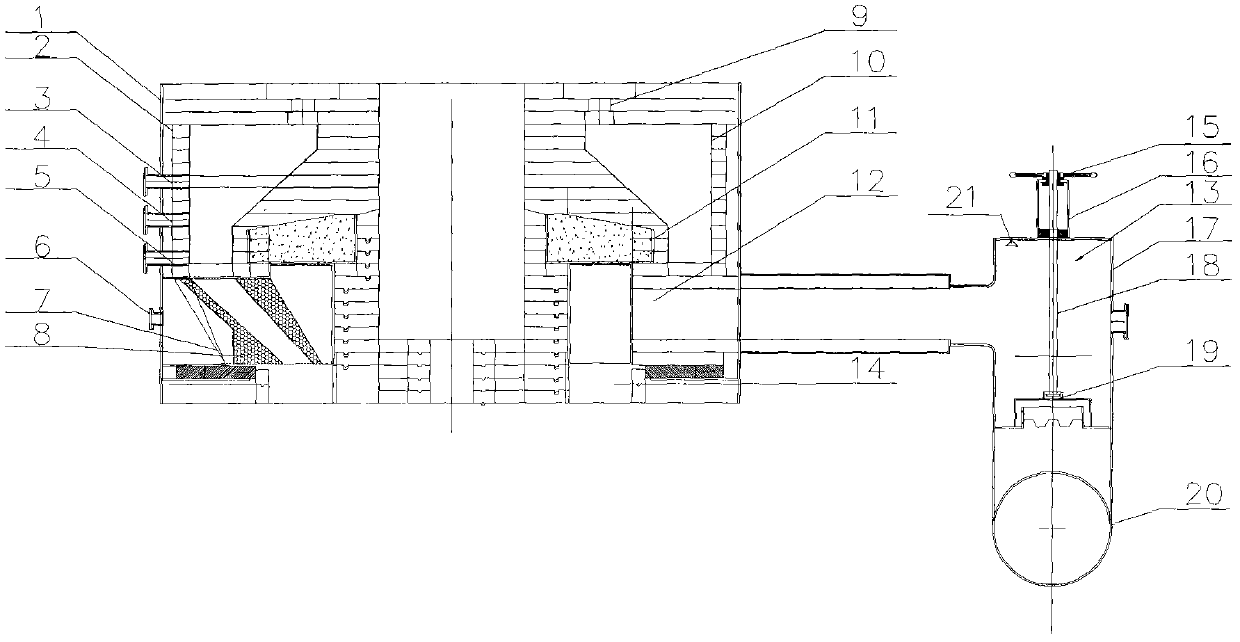

[0007] specific implementation

[0008] A raw gas exporting device for a coal pyrolysis furnace, which includes: a furnace shell 1, a refractory masonry 2, a high material level meter hole 3, a low material level meter hole 4, an observation hole 5, and a raw gas pressure measurement Warm hole 6, heat preservation shell 7, heat preservation material 8, feeding port 9, material level control bin 10, cement block 11, raw gas export channel 12 and carbonization furnace entrance 14; furnace shell 1 is provided with refractory material masonry 2. The refractory masonry 2 is provided with 8 feeding ports 9, which are connected to the material level control bin 10, and the material level control bin 10 is provided with a high material level measuring hole 3. Low material level measurement Hole 4, observation hole 5, raw gas pressure and temperature measurement hole 6 is set on the furnace shell 1, heat preservation shell 7, cement block 11 and raw gas export channel 12 are set under ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com