Agate red ceramic glazing material

A kind of ceramic glaze and glaze technology, which is applied in the field of agate red ceramic glaze, can solve the problem of few varieties, and achieve the effect of crystal clear color and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] ①Raw material processing: After mixing the raw materials evenly according to the proportion, dry them;

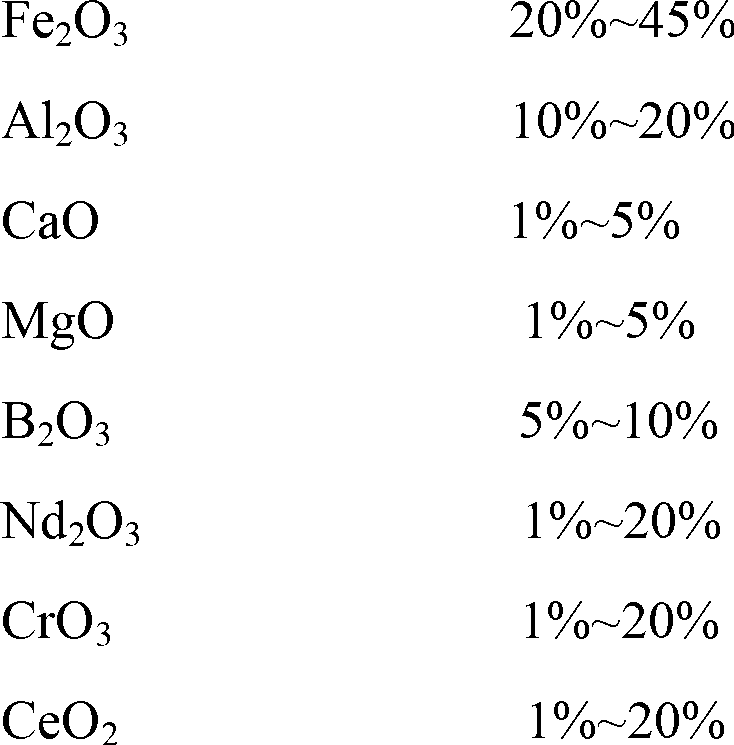

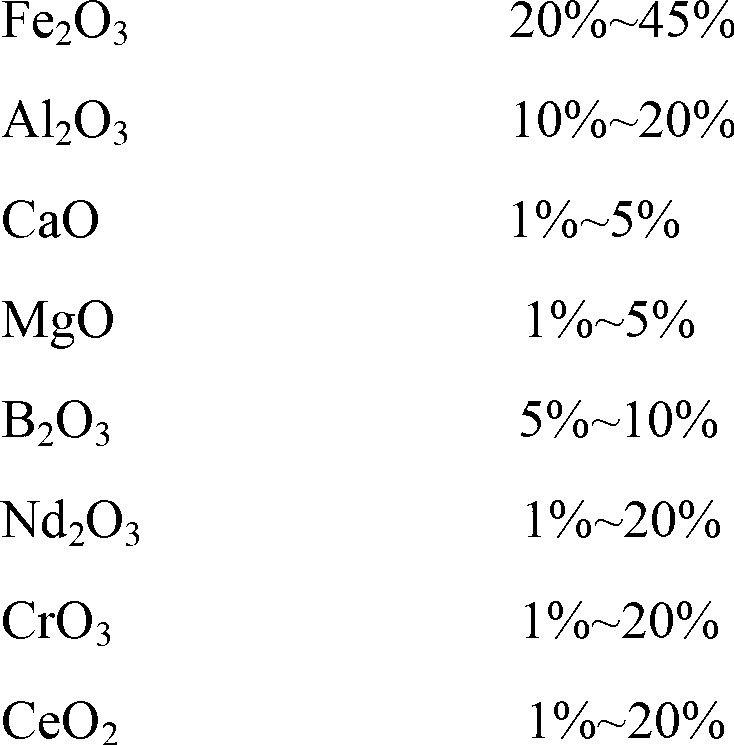

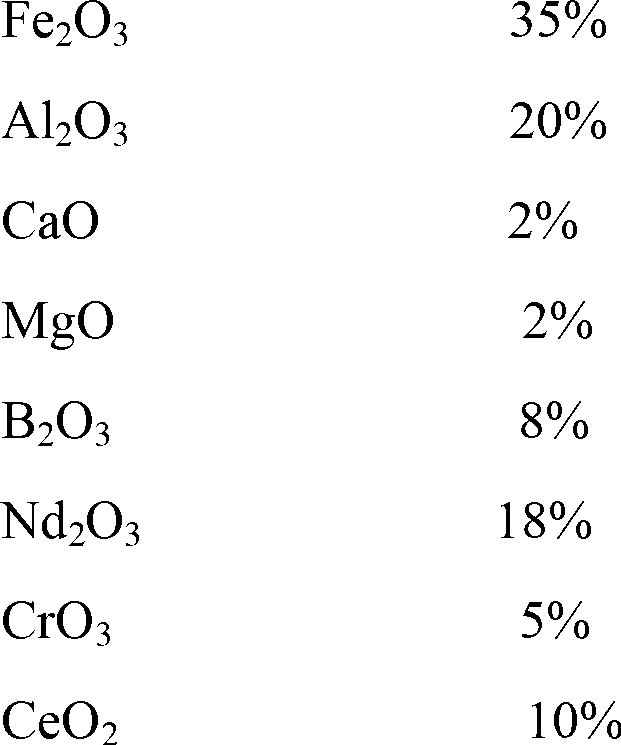

[0038] Described raw material is made up of following components by mass percentage:

[0039]

[0040] The Fe 2 o 3 、Al 2 o 3 , CaO, MgO, B 2 o 3 、Nd 2 o 3 , CrO 3 , CeO 2 The average particle size is 400nm;

[0041] ② Sintering: put the raw material in a crucible and treat it at 1200°C for 4 hours;

[0042] ③Post-processing: crush the product obtained in step ②, and pass through a 200-mesh sieve.

[0043] The obtained pigment is agate red material, which is stable under calcination at 1250°C.

[0044] The raw material of glaze material of the present invention is made up of following components by mass percentage:

[0045] Base 78%

[0046] Pigment 20%

[0047] Auxiliary 2%.

[0048] Described glaze is prepared as follows:

[0049] I. Raw material processing: mix the base material and color material in the glaze raw material evenly;

[0050] II...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com