Multifunctional rolling mill for producing thin metal straps and ultra-thin metal straps

An ultra-thin strip, multi-functional technology, applied in the direction of metal rolling stands, metal rolling mill stands, metal rolling, etc., can solve the problems of single use range, high cost, and production equipment can not meet the demand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

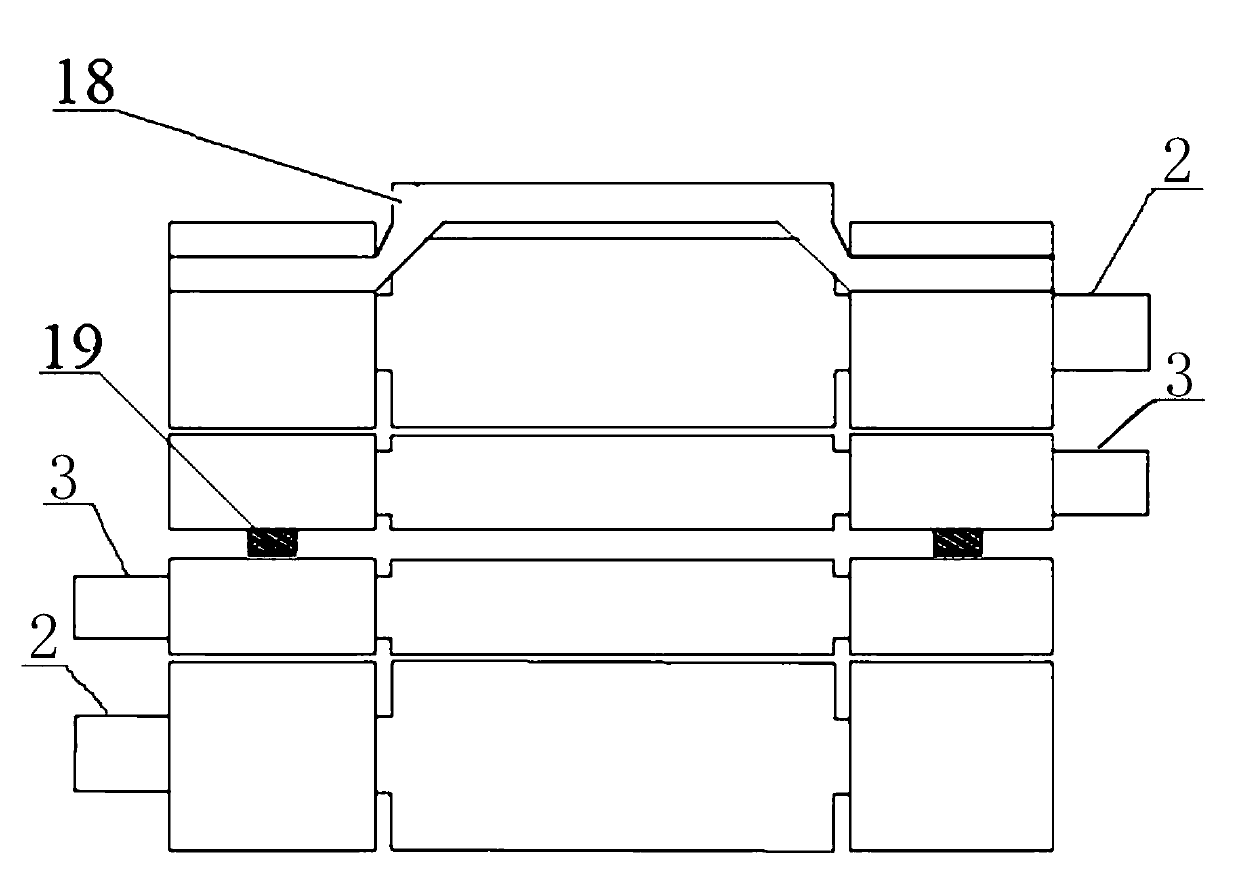

[0053] The four-roll vertical distribution method roll system rolling mill includes a pressing device 1, a pair of vertically distributed work rolls 3 and a pair of support rolls 2, a housing 4 and a base 10, a tension motor 5, a main drive motor 7, a reel 8 and a tension roller 9. The arch 4 is vertically arranged. The contact surface 15 between the arch and the base is fixed on the base 10 by bolts. Both ends of the roll are fixed with sliding bearing housings. The roll and the bearing housing move at the same time. The upper supporting roller 2 bearing housing is balanced by The beam 18 is hoisted, the bearing seat of the lower supporting roller 2 is fixed at the bottom of the archway 4, and the bearing seat of the upper and lower work rolls 3 is connected by the spring 19 between the working rolls. 19 is fixed inside, the upper end of the work roll spring 19 is in contact with the lower surface of the upper work roll 3 bearing seat, there is no connection between the upper s...

Embodiment 2

[0057] Two-roll horizontally arranged horizontally. The rolling mill consists of two horizontally arranged work rolls 3, an arch 4 and a base 10, a main drive motor 7, a feeding port 11 and a discharge port 12. The arch 4 is arranged horizontally by two rolls. The contact surface 14 with the base is fixed on the base 10 by bolts. The described work roll 3 is a work roll 3 with a four-roll vertical arrangement that is disassembled, and the support roll 2 in the four-roll vertical arrangement roll system is used as the work roll 3 in a two-roll horizontal horizontal arrangement.

[0058] Turn on the power supply of the rolling mill system. During rolling, liquid, powder or particles are fed into the roll gap through the feeding port, and the finished strip is obtained after rolling.

Embodiment 3

[0060] The two-roll vertical arrangement method is composed of a pressing device 1, a pair of vertically distributed work rolls 3, a housing 4 and a base 10, a tension motor 5, a main drive motor 7, a reel 8 and a tension roller 9; The work roll 3 is the work roll 3 of the disassembled four-roller vertical arrangement. The supporting roll 2 of the four-roller vertical arrangement is used as the work roll 3 of the two-roller vertical arrangement. The archway 4 is arranged vertically. The contact surface 15 between the archway and the base is fixed on the base 10 by bolts.

[0061] Turn on the power supply of the rolling mill system to perform synchronous or asynchronous rolling of the thin strip blanks. The rolling process is carried out under the condition of strip tension. After multiple passes, the thickness range is below 0.05mm to below 0.005mm. The functional material finished product of the thin strip.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com