Structure of composite table top

A desktop board and panel technology, which is applied to the legs, tables, and furniture parts of general furniture, can solve the problems of wood maintenance requirements, uneven applicability, high maintenance costs, and unfavorable environmental protection, and achieves diverse and simplified fixing methods. The effect of structure, great applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

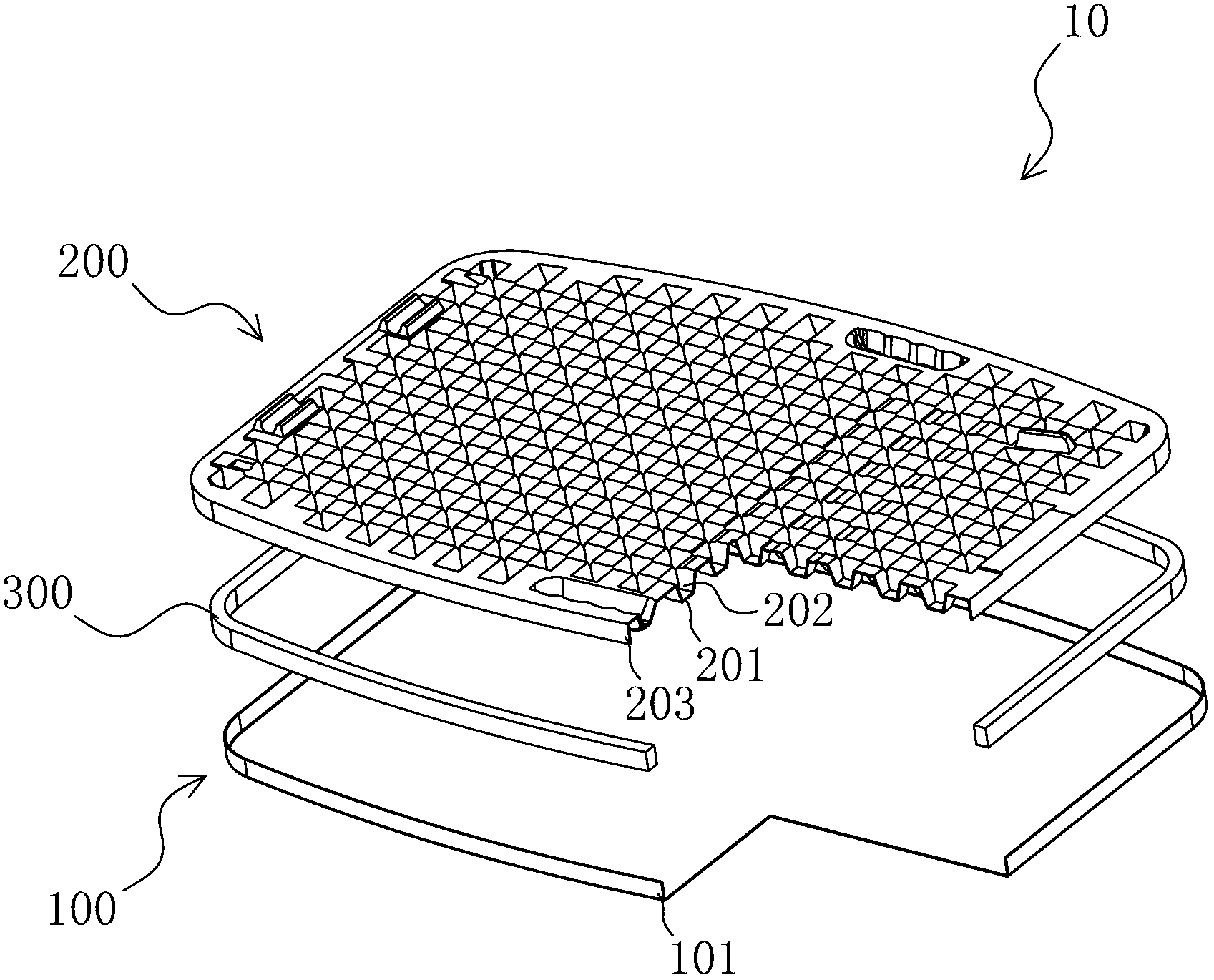

[0036] Such as figure 1 , a three-dimensional exploded view of an embodiment of the present invention, with a schematic cutaway; the composite desktop board 10 utilizes a plastic-absorbing process; The panel 100 is in the shape of a flat plate with an upper flange 101 on its outer periphery;

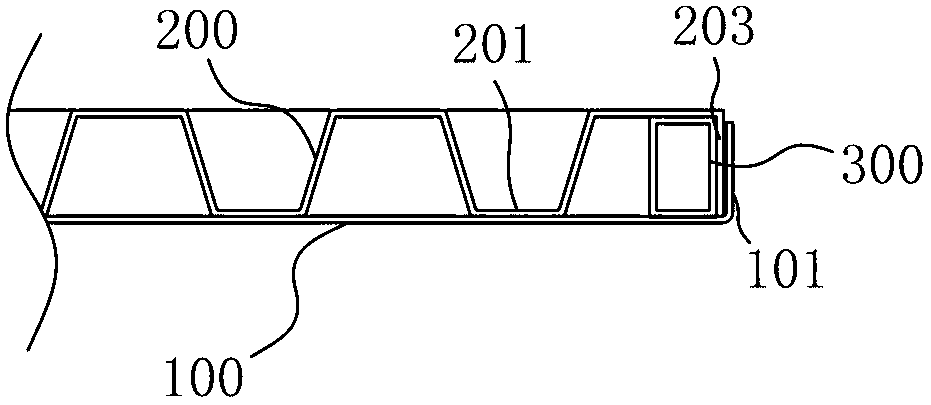

[0037] On the upper surface of the reinforcing plate 200, there are protrusions 201 that are closely adjacent to each other and distributed in a rectangular array. These protrusions 201 have a plane joint surface, and are ultrasonically welded with the inner surface of the panel 100. The area of the plane joint surface is 16 cm. 2 , the actual optional range is 1-25cm 2 .

[0038] The protrusions 201 are staggeredly distributed on the upper surface of the reinforcing plate 200 , not all joint surfaces of the protrusions 201 need to be welded on the inner surface of the panel 100 during actual welding, as long as the joint surfaces of the staggered array are fixed. The reinforcing fr...

Embodiment 2

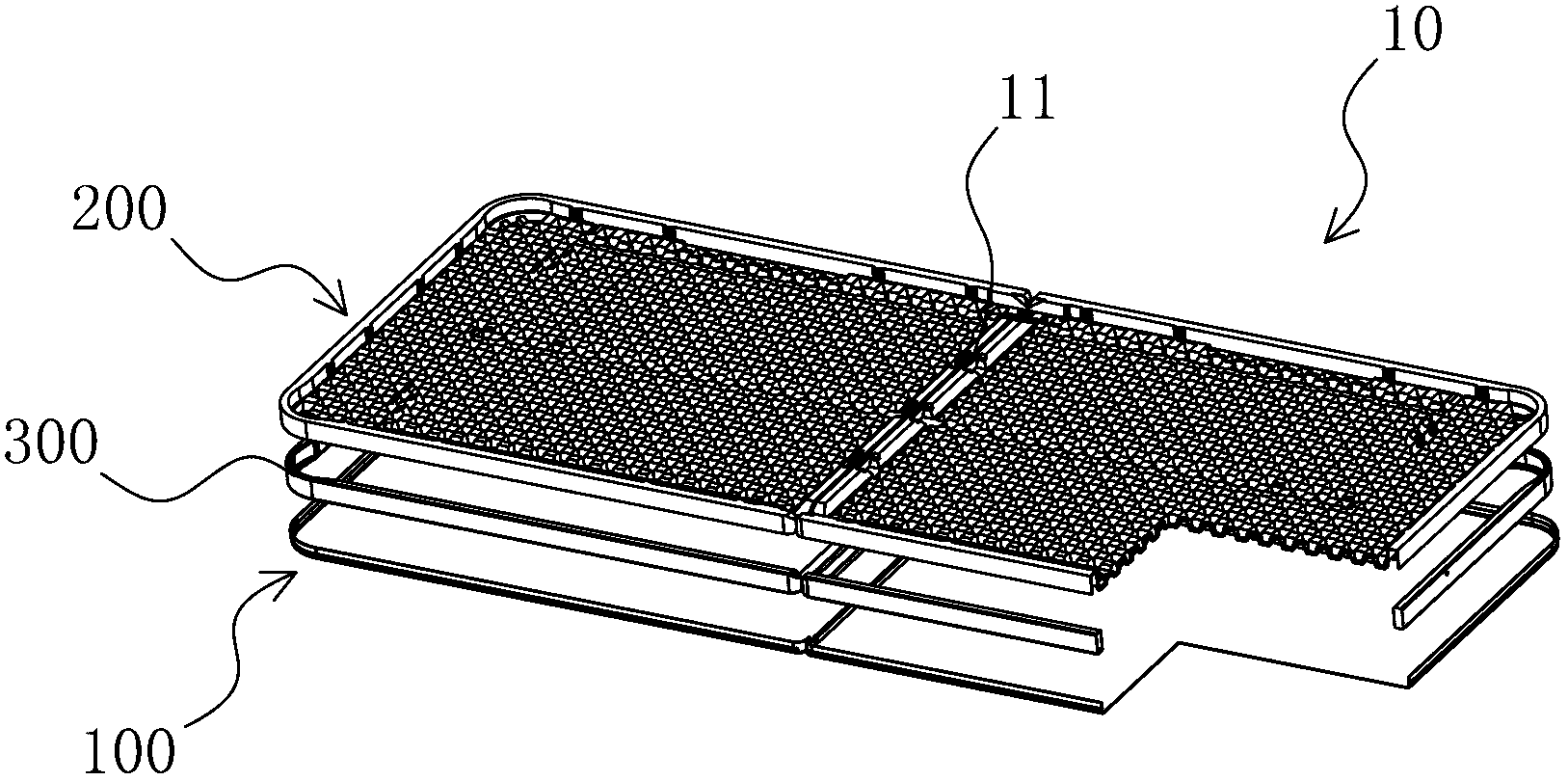

[0042] Such as image 3 , a three-dimensional exploded view of Embodiment 2, with a cutaway diagram; in this embodiment, the basic internal structure of the composite tabletop 10 is similar to that of Embodiment 1, such as the shape, distribution, and combination of protrusions. The difference is that the composite desktop board 10 is composed of two pieces, with a hinge 11 in the center, so that the composite desktop board 10 can be folded and overlapped in the direction of the lower surface of the reinforcement board 200 .

Embodiment 3

[0044] Such as Figure 4 , the three-dimensional exploded view of Embodiment 3, with a cut-away diagram; the composite desktop board 10 still includes a panel 100, a reinforcement board 200 and a reinforcement frame 300; the structure of the panel 100 is the same as that of Embodiments 1 and 2; The protrusions 201 are elongated and distributed in a regular array with gaps between them; the protrusions 201 are arranged at regular intervals in the horizontal direction of the upper surface, both longitudinally and laterally, and have a plane joint surface matching the inner surface of the reinforcing plate 200 . The concave 202 corresponding to the protrusion 201 is also elongated; and the joint surface where the protrusion 201 contacts the inner surface of the panel 100 is also rectangular.

[0045] combine Figure 5 Knowing the details of the positions of each component, the protrusions 201 on the reinforcing plate 200 can also be fixed to the inner surface of the panel 100 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com