Process for production of sparkling fermented beverage

The technology of a fermented beverage and a manufacturing method is applied in the manufacturing field of foamable fermented beverages, which can solve the problems of rising liquid viscosity, low solubility of soybean protein, slow filtration, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] According to the manufacturing method of the sparkling fermented drink of this invention, the sparkling fermented drink which uses malt as a raw material is manufactured.

[0045] First, 25 L of water and 1.5% by weight of neutral protease derived from the genus Bacillus were added to 0.7 kg of purified soybean protein. Enzyme reaction was performed at 50 degreeC for 2 hours, stirring, and the soybean protein decomposition product solution was obtained.

[0046] In addition, using alkaline protease instead of neutral protease as a control, and adjusting the pH of the purified soybean protein aqueous solution to 9.0 with potassium hydroxide before adding alkaline protease, in addition, follow the same operation to obtain soybean protein decomposition product solution.

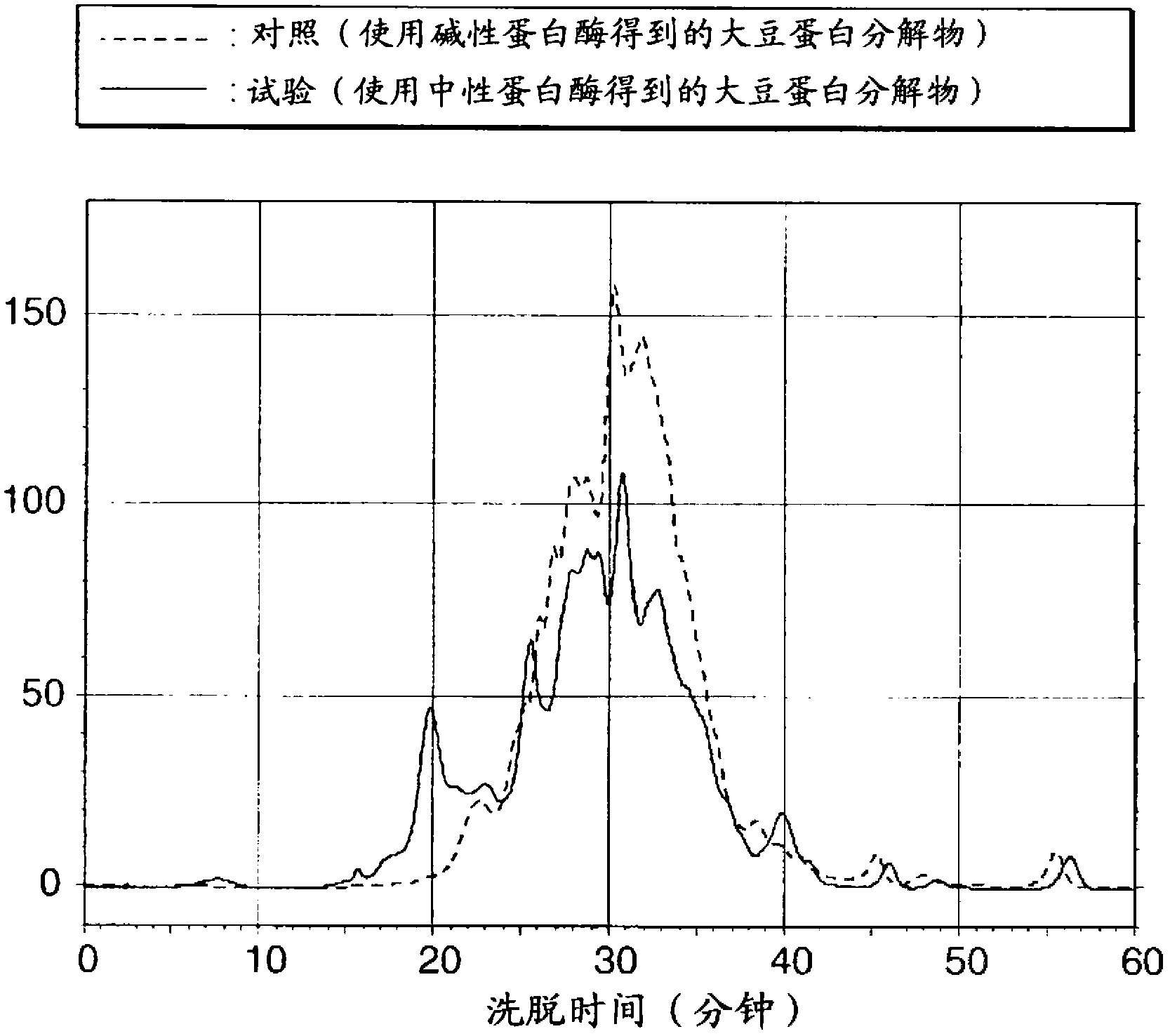

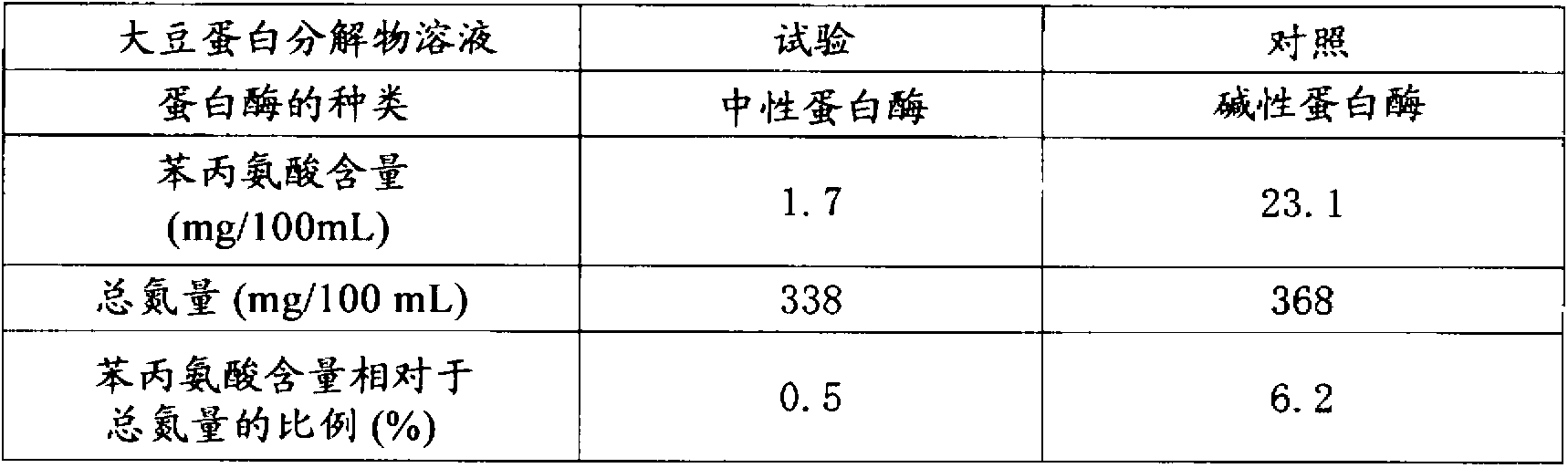

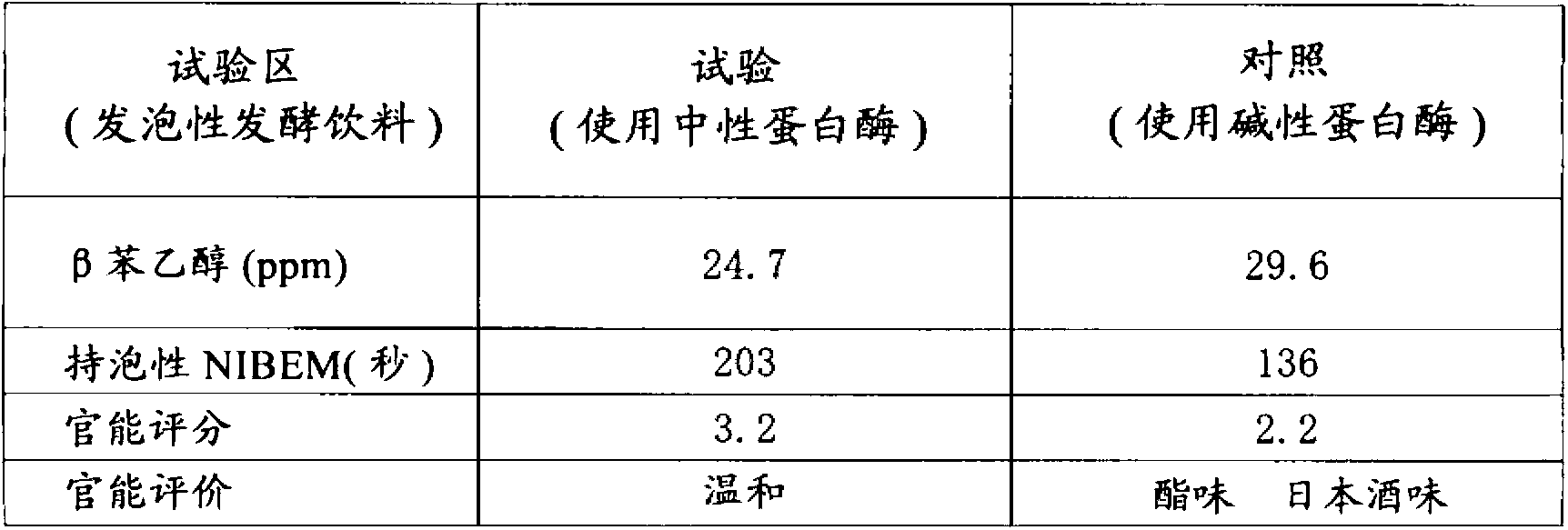

[0047] The total nitrogen content and the phenylalanine content of these soybean protein breakdown product solutions were measured, and the ratio of the phenylalanine content to the total nitrogen conten...

Embodiment 2

[0060] A foamable fermented drink that does not use malt as a raw material is manufactured using soybean protein hydrolyzate decomposed by various proteases. Neutrase (manufactured by Novozymes) and α-enzyme (manufactured by Danisco) were used as neutral proteases, and Esperase (manufactured by Novozymes) and Alcalase (manufactured by Novozymes) were used as alkaline proteases. These enzymes are all enzymes from the genus Bacillus.

[0061] First, 200 mL of water and the protease listed in Table 3 were added to 6 g of purified soybean protein. Regarding the test plots 5 and 6, the pH was adjusted to 11.0 and 9.0, respectively, using sodium hydroxide before adding the enzyme. After performing an enzyme reaction at 50 degreeC for 2 hours, stirring, it boiled for 20 minutes, and obtained the soybean protein decomposition product solution. In addition, in Table 3, "the addition amount (weight%) of protease" means the ratio (weight%) with respect to soybean protein weight.

[00...

Embodiment 3

[0068] A sparkling fermented beverage using malt as a raw material is produced by the method for producing a sparkling fermented beverage of the present invention.

[0069] First, 25 L of water and 1.5% by weight of neutral protease derived from the genus Bacillus were added to 3.0 kg of defatted soybeans. Enzyme reaction was performed at 50 degreeC for 2 hours, stirring, and the soybean protein decomposition product solution was obtained.

[0070] The total nitrogen content and phenylalanine content of these soybean protein decomposition product solutions were measured, and the ratio of the phenylalanine content to the total nitrogen content was calculated. The results are shown in Table 4. In the soybean protein degradation product solution (test) obtained by neutral protease, the ratio of the phenylalanine content with respect to the total nitrogen amount was very low.

[0071] [Table 4]

[0072] Soybean Protein Decomposition Solution

test

Types of Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com