Low bending loss low water peak single mode fiber with stable diameter and production process of low water peak single mode fiber

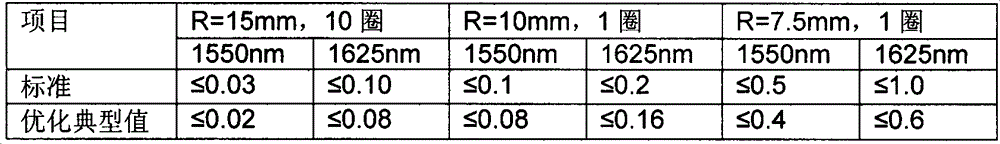

A bending loss, single-mode optical fiber technology, applied in the direction of multi-layer core/clad optical fiber, clad optical fiber, manufacturing tools, etc., can solve the problems of complex refractive index control process, affecting normal use, and large peeling force value. Achieve superior bending resistance, improve work efficiency, and excellent coating peeling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

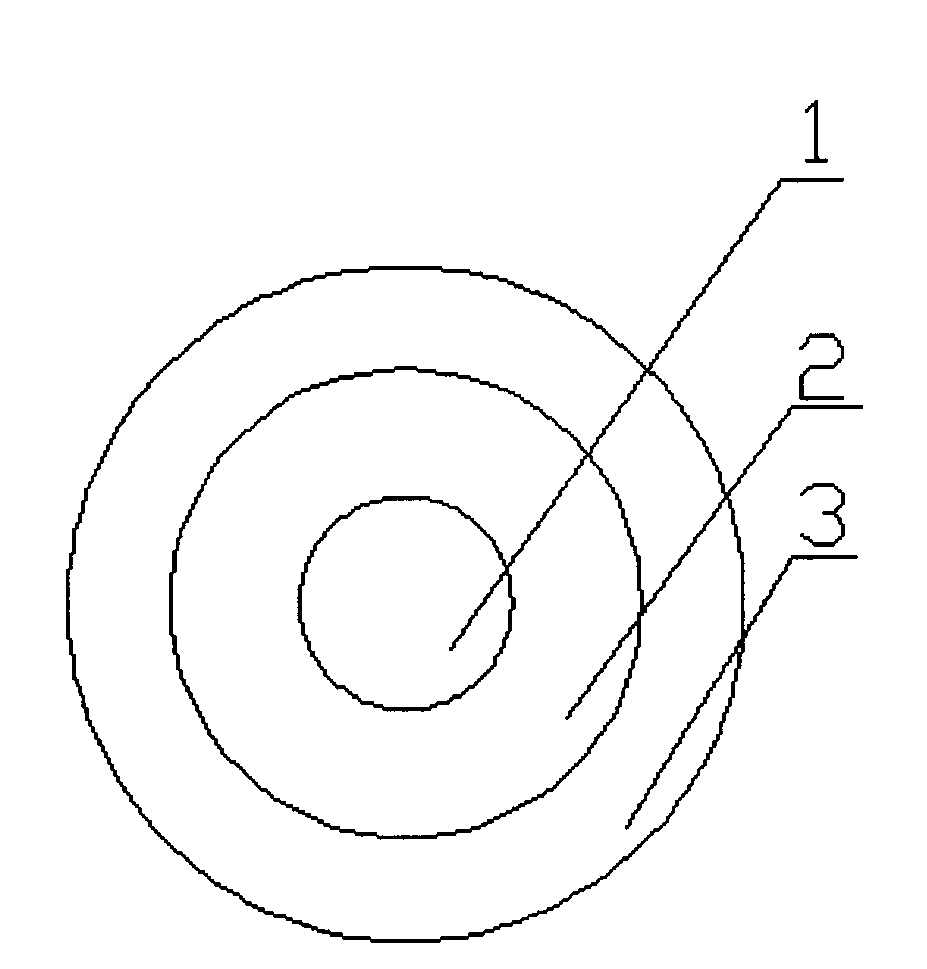

[0015] A low water peak single-mode optical fiber with low bending loss and stable diameter. The cladding 1 of the optical fiber has a diameter of 124-125 μm, the inner coating 2 has a diameter of 190-195 μm, and the outer coating 3 has a diameter of 240-246 μm.

[0016] A production process of a low water peak single-mode optical fiber with low bending loss and stable diameter, comprising the following steps:

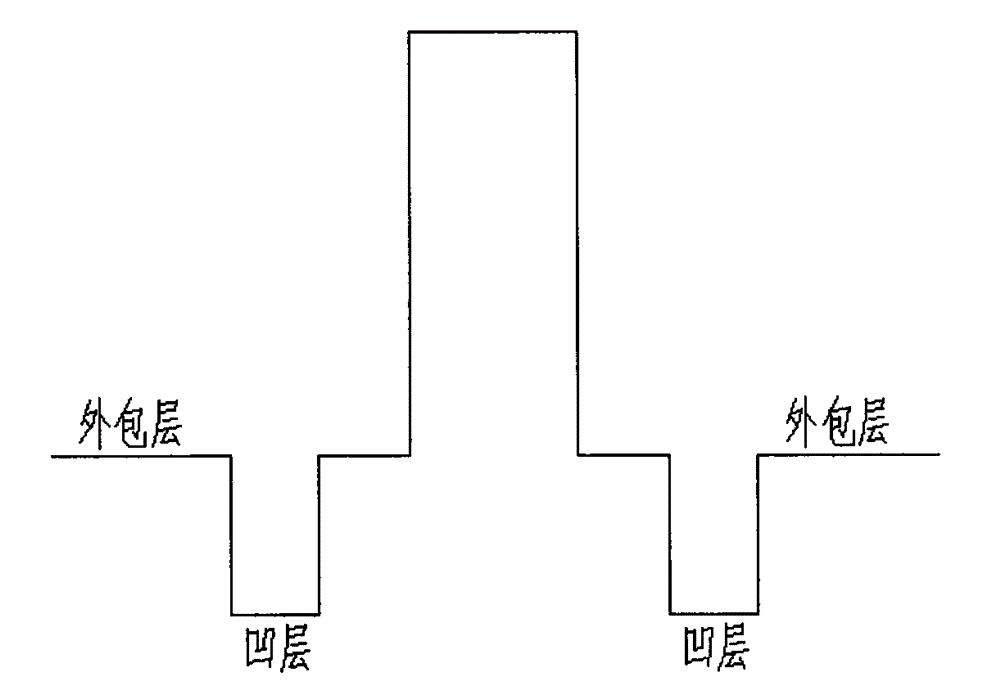

[0017] (1) Preform wire drawing: Assemble the preform on the drawing tower, start drawing, add F element in the core of the optical fiber, the refractive index profile of the preform is a depressed cladding structure, and the range of the depression is 0.05% to 0.14 %;

[0018] (2) Coating: Coat the semi-finished optical fiber after drawing, and the coating coating adopts UV-curable coating with a modulus controlled at 0.6-1.2MPa;

[0019] (3) Curing: Curing the coated optical fiber. The distance between coating and curing is 1-3 meters. The curing adopts ultraviolet ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com