Ultrasonic impact needle speed measurement experiment equipment and application thereof

A technology of ultrasonic impact and experimental equipment, which is applied in the field of ultrasonic impact, and can solve the problems of small distance between the impact needle and the test piece, complex changes in the velocity of the impact needle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: Assembling an infrared velocimeter

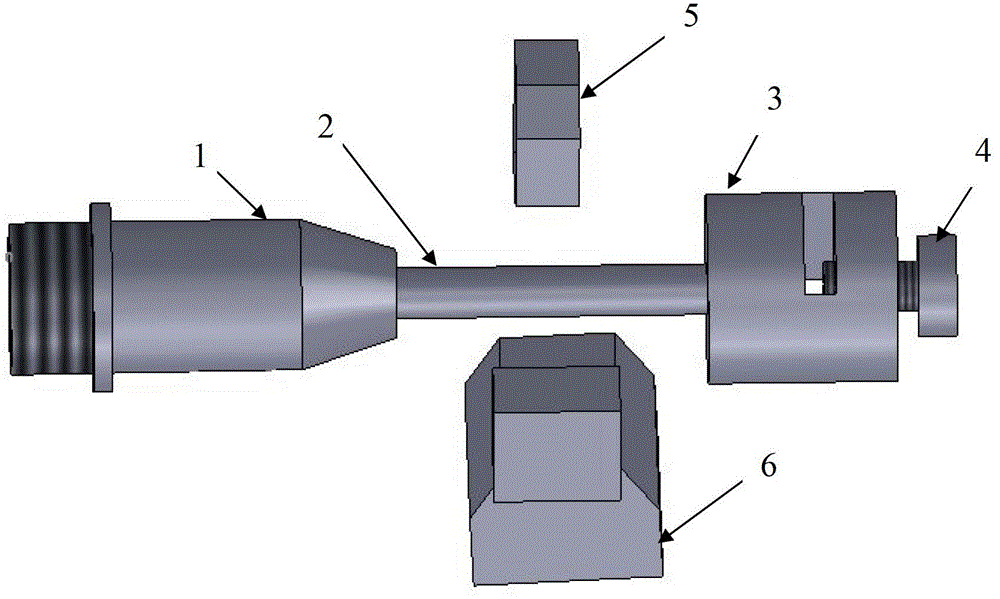

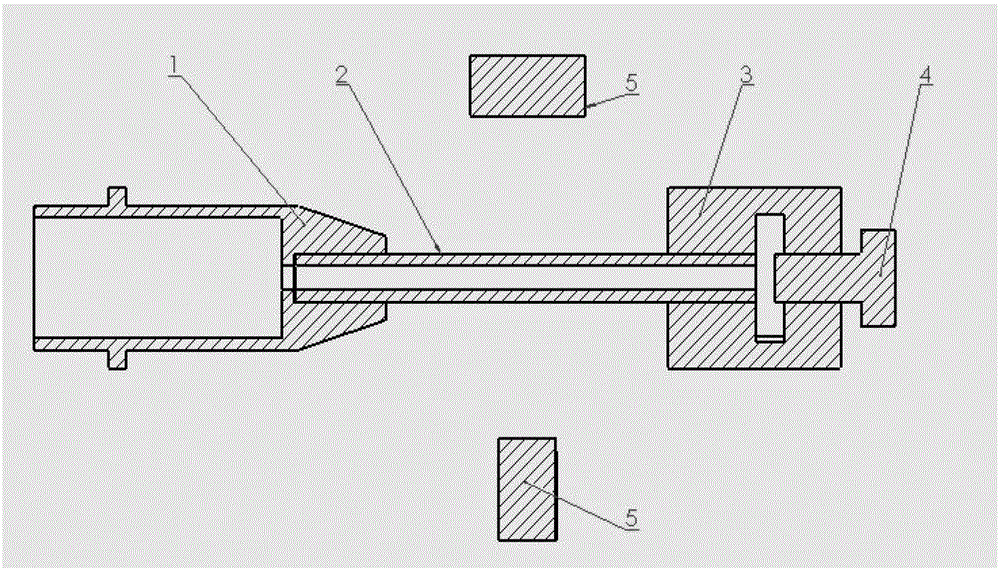

[0025] as attached Figure 1-2 As shown, in the experimental process of the present invention, an infrared velocimeter can be used to collect the velocity of the impacting needle during the impact process, and its structure includes: a base 1, a quartz tube 2, a sample holder 3, a fixing screw 4 and an infrared velocimeter 5.

[0026] The end of the cylindrical base is threaded to match the ultrasonic impact gun body, and it also has a loading and unloading protrusion, which can be used to fix the base and the gun body with a flange. connect. The role of the quartz tube is to extend the stroke of the impact needle, which is beneficial to the observation and collection of the speed change of the impact needle during the impact process, and to connect the base and the sample holder. The sample is clamped into a cylindrical shape, and one end has a hole with the same diameter as the outer diameter of the quartz tube, the...

Embodiment 2

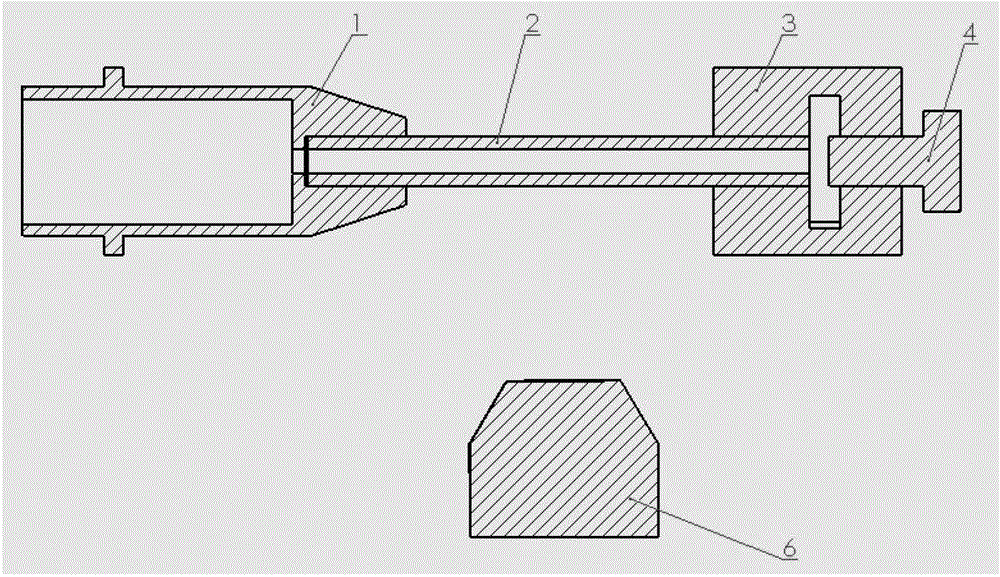

[0027] Example 2: Assembling a high-speed camera

[0028] as attached Figure 1-3 As shown, in the experimental process of the present invention, an infrared velocimeter can be used to collect the impact needle velocity during the impact process, and its structure includes: a base 1, a quartz tube 2, a sample holder 3, a fixing screw 4 and a high-speed camera 6.

[0029] The end of the cylindrical base is threaded to match the ultrasonic impact gun body, and it also has a loading and unloading protrusion, which can be used to fix the base and the gun body with a flange. connect. The role of the quartz tube is to extend the stroke of the impact needle, which is beneficial to the observation and collection of the speed change of the impact needle during the impact process, and to connect the base and the sample holder. The sample is clamped into a cylindrical shape, and one end has a hole with the same diameter as the outer diameter of the quartz tube, the other end has a thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com