Detection device of bonding strength between rotor core and magnet ring

A technology of bonding strength and rotor iron core, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve problems such as the inability to accurately reflect the bonding strength of the rotor iron core and the magnetic ring, achieve convenient operation, accurate detection accuracy, and ensure The effect of pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

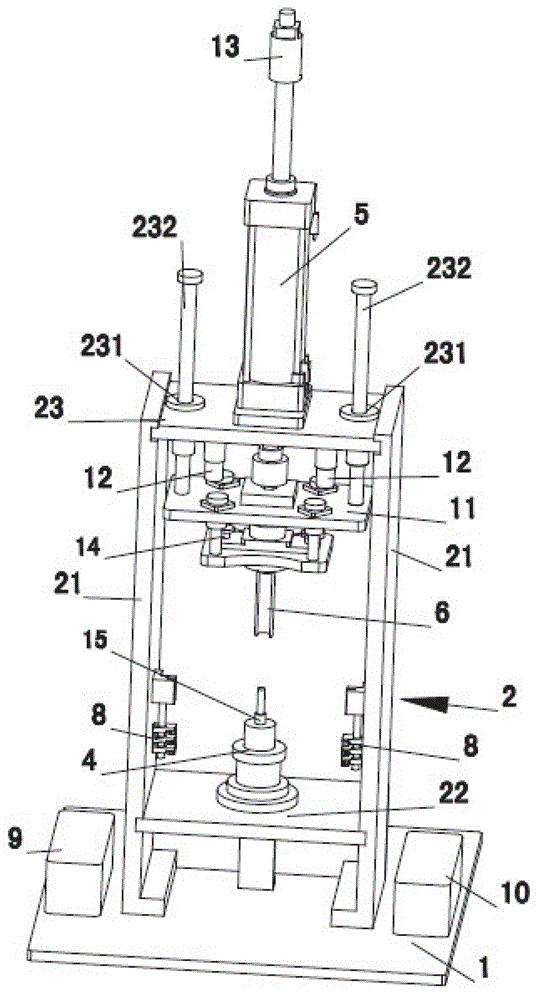

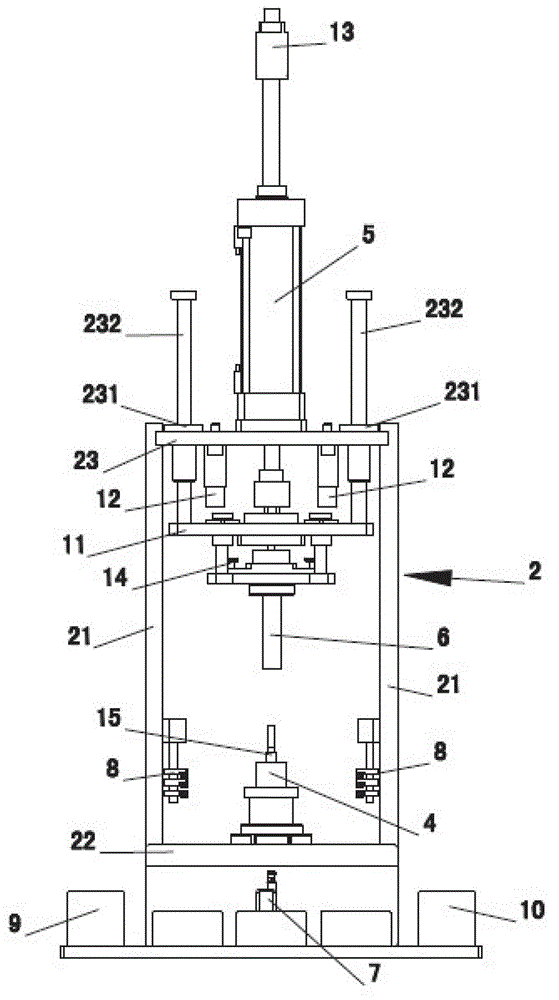

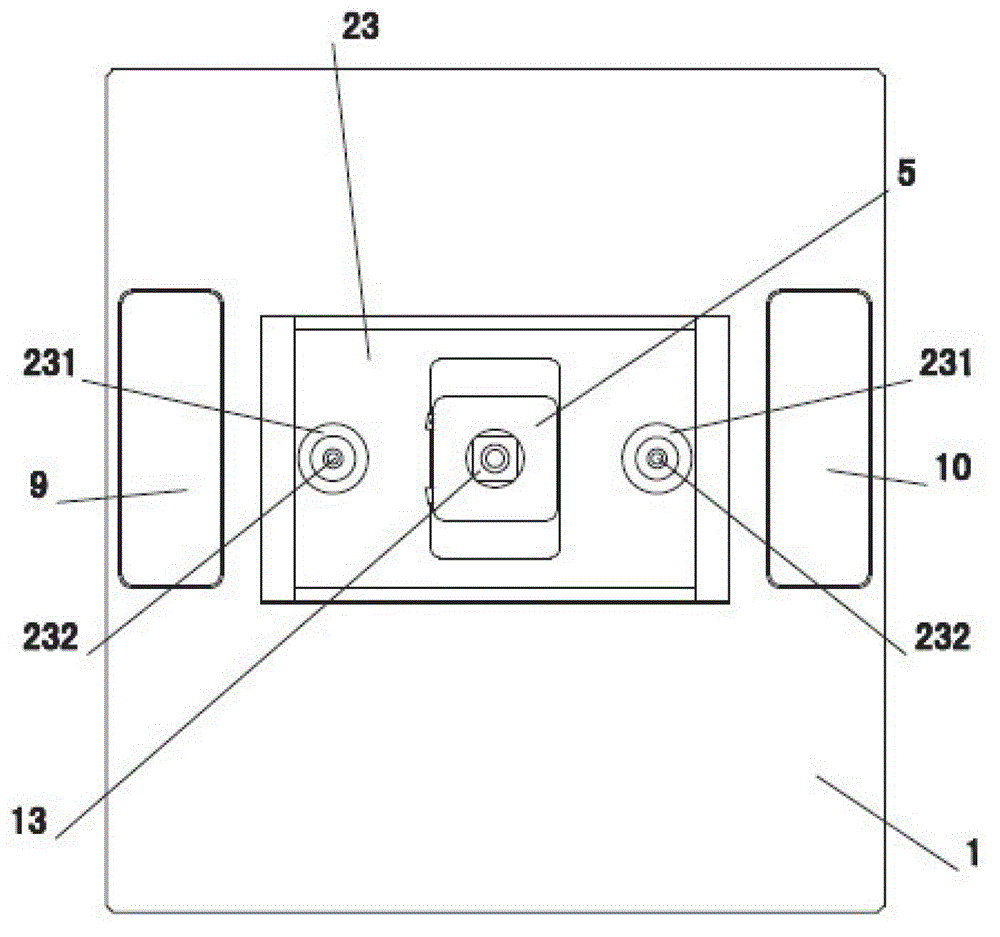

[0023] like Figure 1~3 Shown, a rotor iron core and magnetic ring bond strength detection device, including worktable 1, frame 2, workpiece placement 4 and detection mechanism; the frame 2 is arranged on the workbench 1, the frame 2 It is mainly composed of a column 21, a bottom plate 22 and a top plate 23, the bottom plate 22 is suspended in the lower part of the column 21; the bottom plate 22 is provided with a workpiece placement position 4; the detection mechanism is arranged on the top plate 23;

[0024] Described detection mechanism comprises pressing down cylinder 5, depression rod 6 and displacement sensor 7; Described depression rod 6 is vertically arranged on the below of described top board 23, and described down pressing cylinder 5 is fixedly arranged on top board 23, and its action end Act on the pressure rod 6, and drive the pressure rod 6 to move downward; the displacement sensor 7 is arranged below the bottom plate 22 corresponding to the workpiece placement p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com