Shell of illuminating device and manufacturing method thereof and illuminating device with shell

A technology for a lighting device and a manufacturing method, which is applied to the cooling/heating device of the lighting device, the parts of the lighting device, the damage prevention measures of the lighting device, etc., and can solve the problem of loose clamping, poor sealing effect, and extrusion of the sealing ring The degree of inconsistency and other problems, to achieve the effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

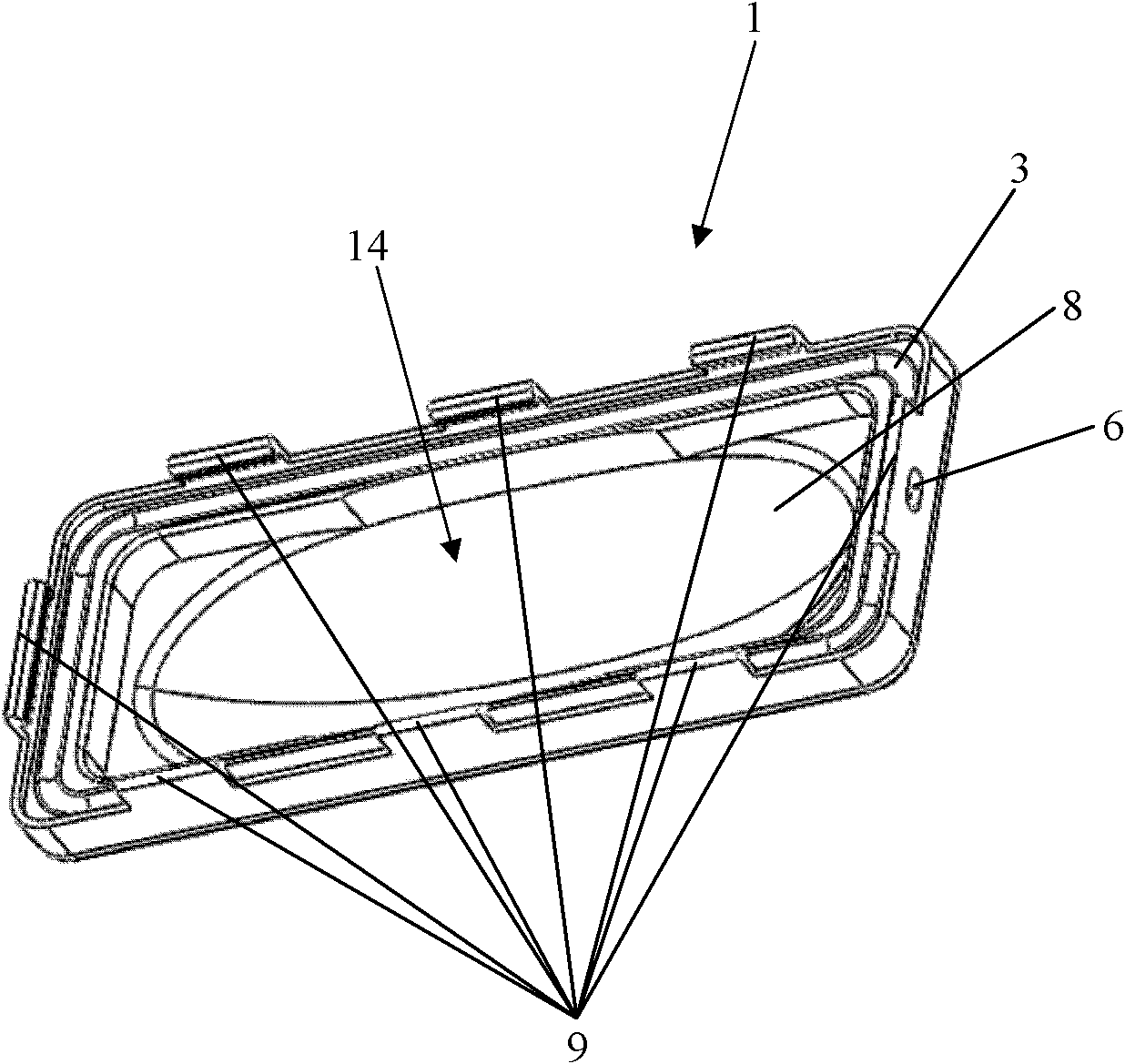

[0025] figure 1 A schematic diagram of the upper housing part 1 of the housing according to the present invention is shown, as can be seen from the figure, the upper housing part 1 has a top surface designed as a light-transmitting cover 8 and four vertically protruding from the top surface. side walls, these sides jointly define the assembly cavity 14. Additionally, from figure 1 As can be seen in the figure, first grooves 3 extending on each end surface are formed on the end surfaces of the four side walls. Meanwhile, hooks 9 are also formed on the four side walls. In the design solution of the present invention, the transparent cover 8 can be made of transparent glass or plastic. In addition, in figure 1 It can also be seen in the figure that an injection hole 6 leading into the filling channel 5 is also formed on the upper casing part 1 for filling the potting compound 16 into the casing through the injection hole 6 .

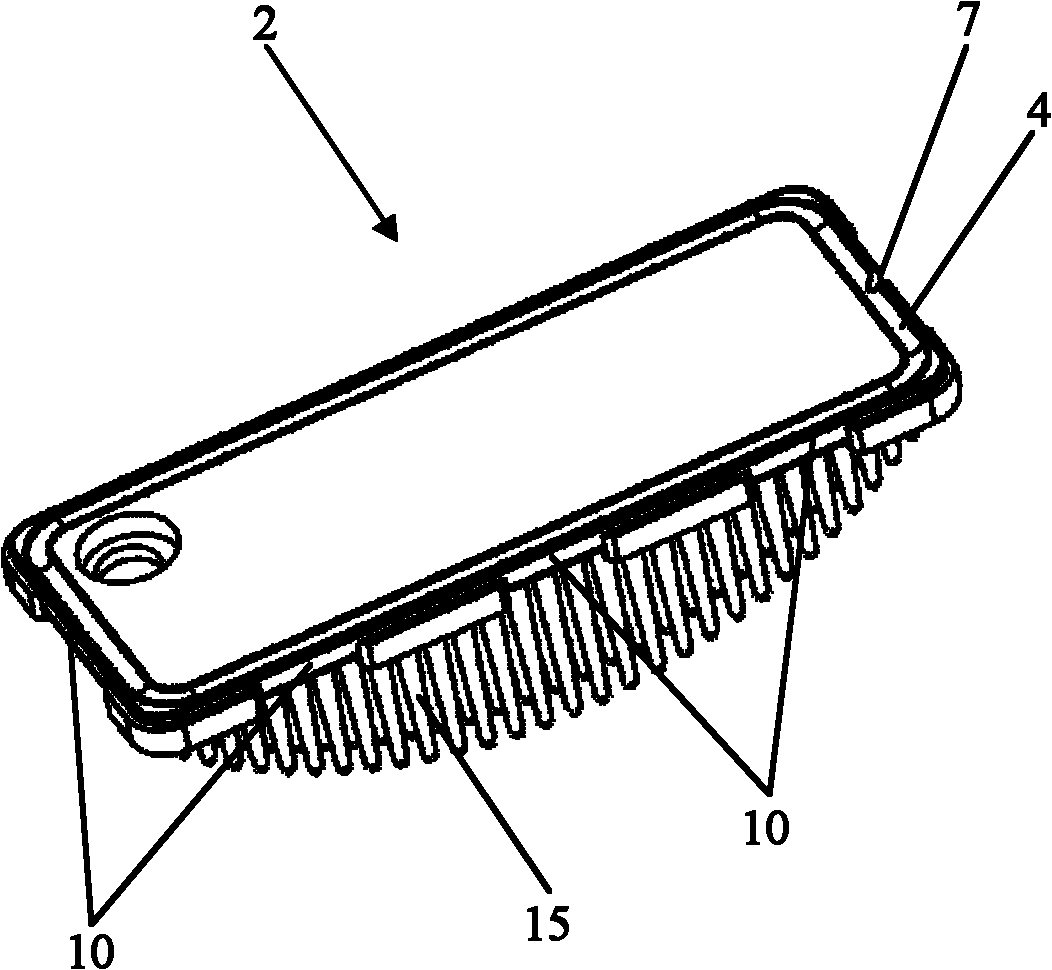

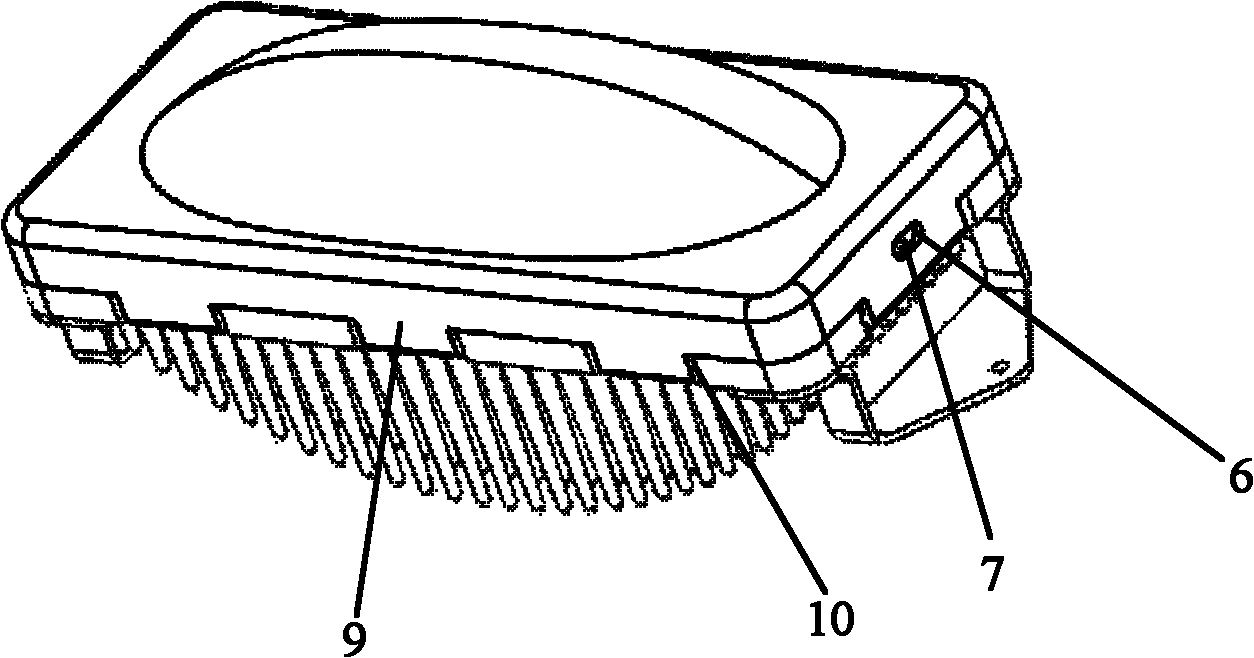

[0026] figure 2 A schematic view of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com