Active reinforced filling wall and construction method

An active technology for backfilling walls, applied in the fields of backfills, earthwork drilling, safety devices, etc., can solve the problems of low early strength of masonry walls, difficulty in laying reinforcement bars, and long time required to achieve simple and improved construction. Initial load-carrying capacity and effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

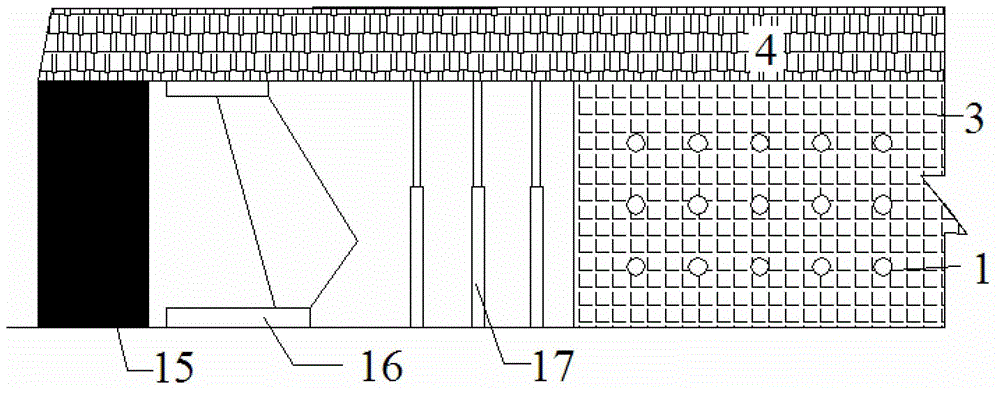

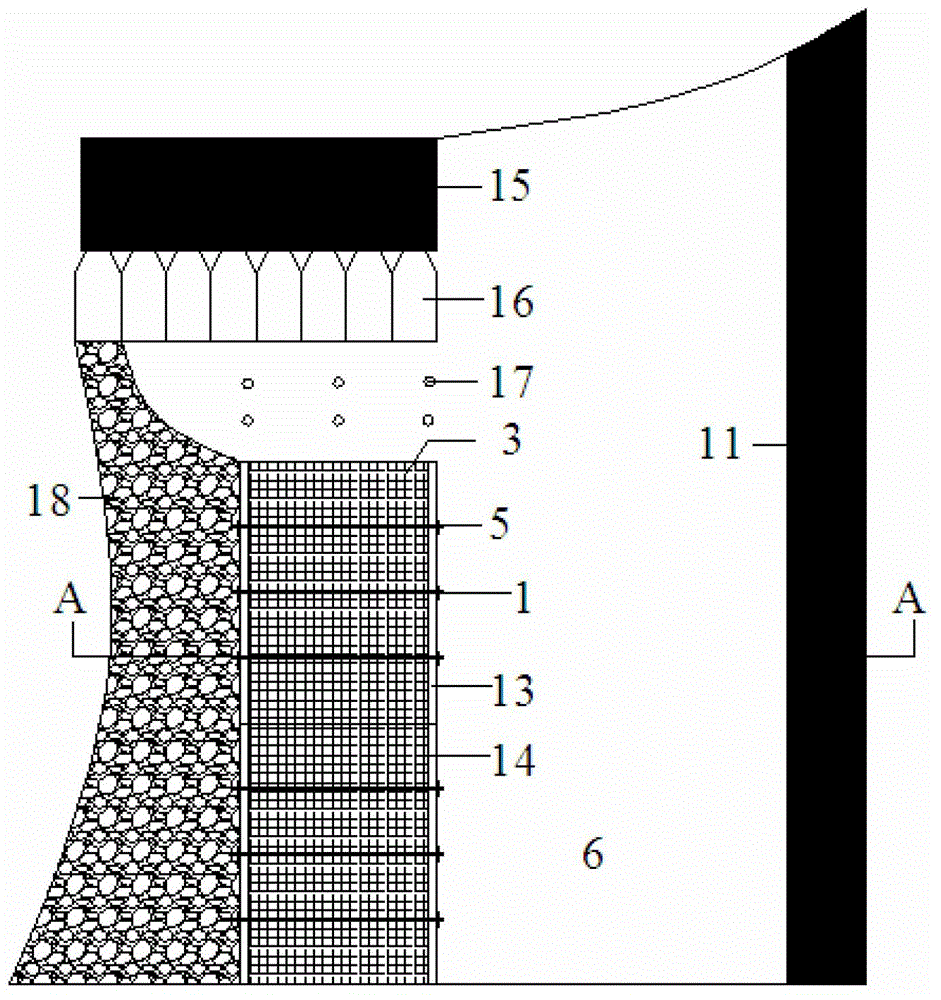

[0032] The present invention will be further described below in conjunction with the accompanying drawings.

[0033] As shown in the figure, the reference numerals: anchor rod 1; anchor cable 2; filling material 3; roof plate 4; 11. Rigging 12, formwork 13, filling bag 14, coal mining face 15, hydraulic support 16, single pillar 17, goaf 18, polyester film 19.

[0034] An actively reinforced filling wall, which includes: anchor rod 1 or anchor cable 2, filling material 3, nut 5, rigging 12, tray 7, formwork 13, filling bag 14, and it also includes a hollow tubular anchoring agent 10; The anchor rod 1 is a fully threaded anchor rod, and each anchor rod is equipped with two nuts 5; the anchor cable 2 is a prestressed anchor cable, and each anchor cable is equipped with two sets of slings 12, and the length of the anchor rod 1 or the anchor cable 2 is long The thickness of the wall; the hollow tubular anchoring agent 10 is prefabricated into a hollow tube shape by the anchoring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com