Refining method of crude epalrestat product

A technology of epalrestat and a refining method, which is applied to the purification of medicine and the refining field of crude epalrestat, can solve the problems of inability to obtain high-purity epalrestat and the like, and achieves easy operation, mild reaction conditions, and high yield. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

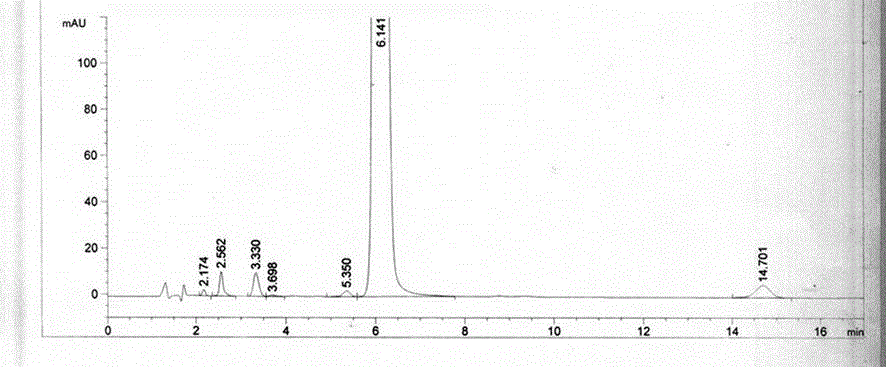

Embodiment 1

[0031] The method for refining crude epalrestat of the present invention, the detailed steps of the refining method are as follows:

[0032] a. One-time refining: first dissolve 10g crude epalrestat in 30ml solvent tetrahydrofuran, heat to 55~65℃ to completely dissolve the crude epalrestat, stop heating after complete dissolution, and then slowly add 70ml solvent isopropyl ether. After adding, a small amount of red solid precipitated. Continue heating to 55~65℃ to completely dissolve the red solid and stop heating. Cool naturally to crystallize for 5h. After crystallizing, filter, obtain wet product of epalrestat after filtration. The obtained wet product of epalrestat was dried, the drying temperature was 100°C, and the drying time was 1h. After drying, 8.0g of the first refined epalrestat was obtained, and the yield was 80.0%;

[0033] b. Secondary refining:

[0034] Add 8.0g of epalrestat after first refining in step a to 24ml of solvent tetrahydrofuran, heat to 55~65℃ to complet...

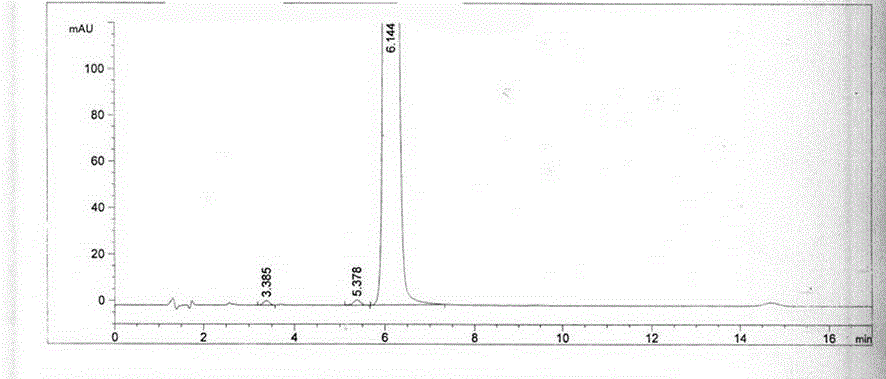

Embodiment 2

[0036] The method for refining crude epalrestat of the present invention, the detailed steps of the refining method are as follows:

[0037] a. One-time refining: first dissolve 10g crude epalrestat in 40ml solvent tetrahydrofuran, heat to 50~55℃ to completely dissolve the crude epalrestat, stop heating after complete dissolution, then slowly add 80ml solvent isopropyl ether, After adding, a small amount of red solid precipitated out. Continue heating to 50~55℃ to completely dissolve the red solid and stop heating. Cool naturally for 5.5h to crystallize, filter after crystallizing, and obtain the wet product of epalrestat after filtering. The resulting wet product of epalrestat was dried at a drying temperature of 90°C and a drying time of 2h. After drying, 8.1 g of epalrestat was obtained after the initial purification, with a yield of 81.0%;

[0038] b. Secondary refining:

[0039] Add 8.1g of epalrestat after the first refining in step a to 32.4ml of solvent tetrahydrofuran, heat...

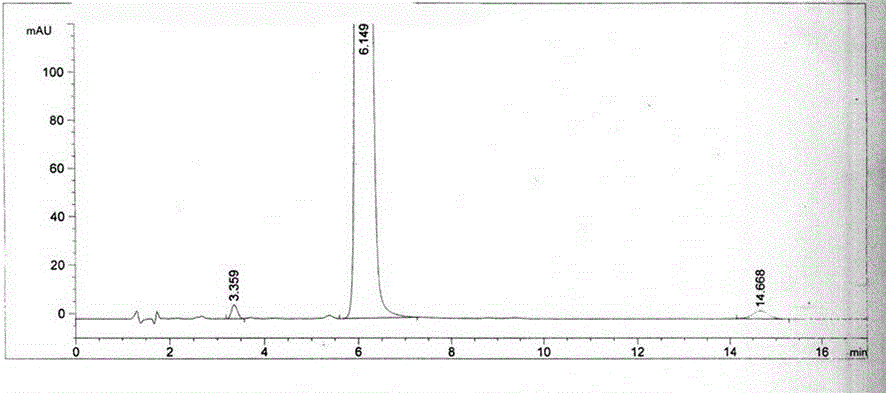

Embodiment 3

[0041] The method for refining crude epalrestat of the present invention, the detailed steps of the refining method are as follows:

[0042] a. One-time refining: first dissolve 10g crude epalrestat in 20ml solvent tetrahydrofuran, heat to 65~70℃ to completely dissolve the crude epalrestat, stop heating after complete dissolution, then slowly add 60ml solvent isopropyl ether, After adding, a small amount of red solid precipitated out. Continue heating to 65~70℃ to completely dissolve the red solid and stop heating. Cool naturally to crystallize for 6h, filter after crystallizing, and obtain a wet product of epalrestat after filtration. The obtained wet product of epalrestat was dried, the drying temperature was 120°C, and the drying time was 1h. After drying, 8.22g of the first refined epalrestat was obtained, and the yield was 82.2%;

[0043] b. Secondary refining:

[0044] Add 8.22g of epalrestat after first refining in step a to 16.5ml of solvent tetrahydrofuran, heat it to 65~70...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com