Hoisting method using three traveling cranes with unequal loads

A technology of unequal and heavy objects, applied in the field of mechanical hoisting, can solve the problems of high cost, large impact, difficulty of crawler crane or truck crane entering the construction site, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

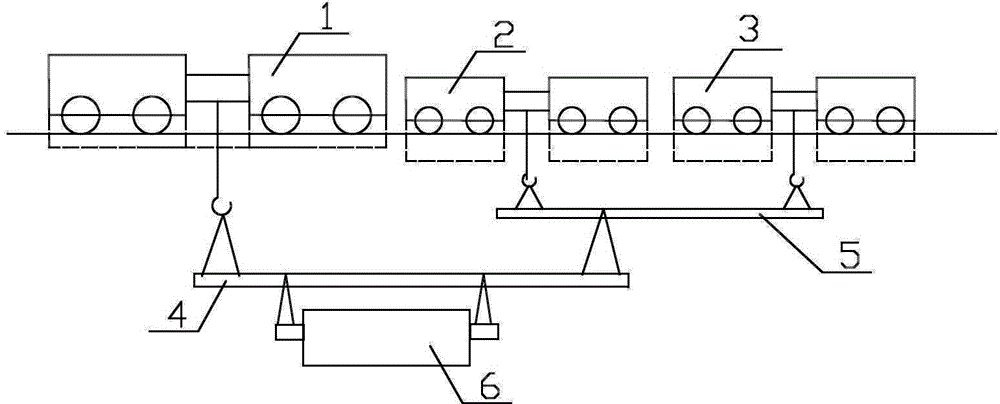

[0015] As shown in the figure: During the construction process, three cranes are used to hoist large equipment into place. The specific technical solutions adopted are:

[0016] 1) Calculate the total load capacity of the three cranes before construction, and require that the weight of the heavy object 6 to be hoisted should not exceed the total load of the three cranes 1, 2, and 3. Then, according to the manufacturer's design instructions, calculate whether the force of the factory's column will be abnormal when the crane straddles three cranes and is in the hoisting area at the same time. After all the calculation results meet the design requirements, the heavy objects can be hoisted by three cranes.

[0017] 2) Determine the arrangement positions of the first main girder 4 and the second main girder 5 in sequence according to the lifting capacity of the three cranes. Comparing the lifting capacity of the two cranes on both sides, the one with the larger lifting capacity is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com