Connection rod type nozzle mechanism

A connecting rod type and nozzle technology, applied in the field of nozzle mechanism, can solve the problems of complex switch valve structure, influence of product injection molding, short service life, etc., and achieve the effects of low cost, easy maintenance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

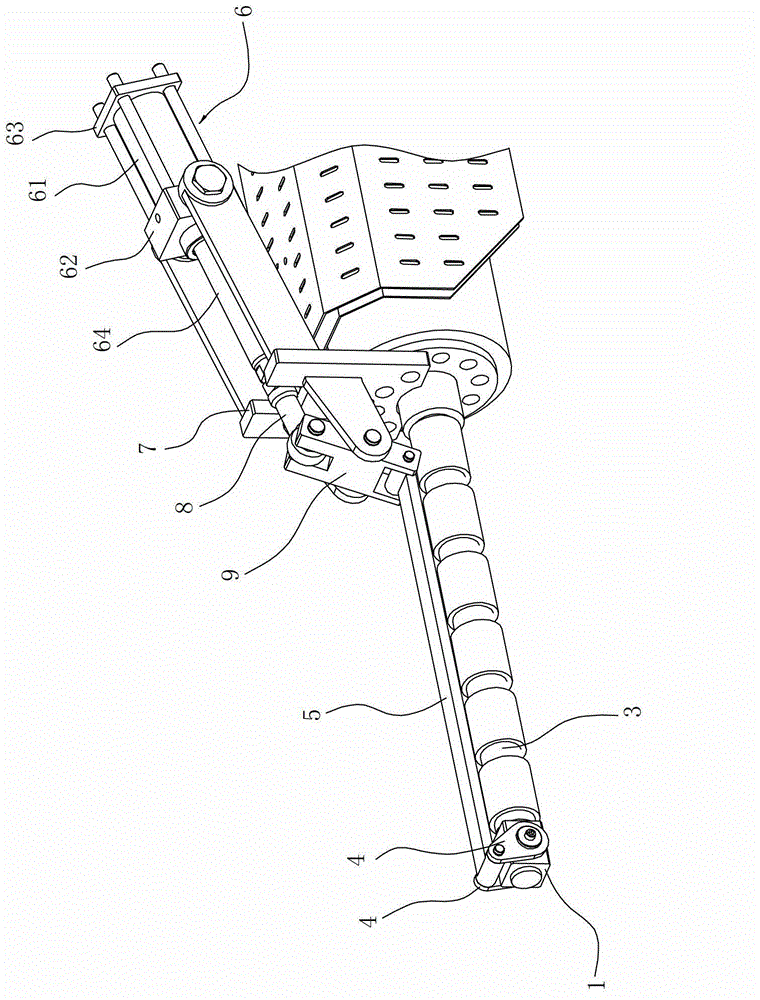

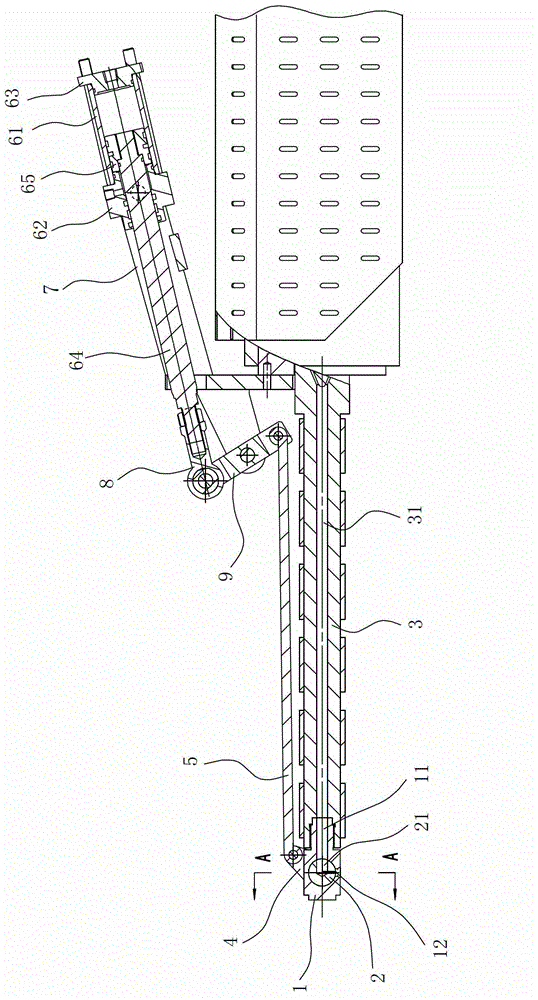

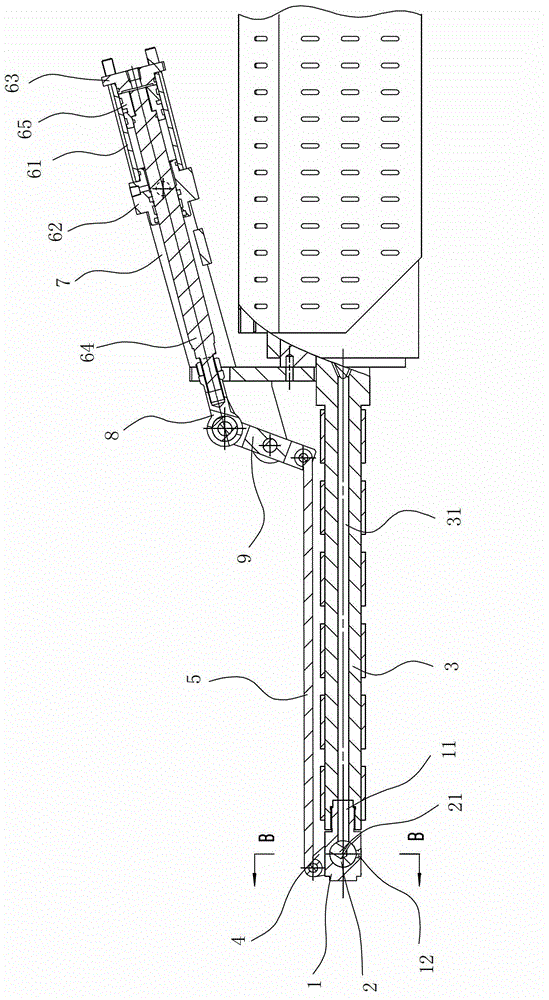

[0028] Such as Figure 1 to Figure 9 As shown, the link type nozzle mechanism includes a nozzle 1, a rotating shaft 2 and a power source, wherein there is an injection channel in the nozzle 1, and the injection channel is composed of a transverse channel 11 connected with an axial flow channel 31 in the small barrel 3 and It is composed of a vertical channel 12 perpendicular to the horizontal channel 11 and with the injection port 121 facing downwards. The nozzle 1 is provided with an axis hole 13 that is located at the junction of the horizontal and vertical channels and is perpendicular to the horizontal and vertical channels. The above-mentioned rotating shaft 2 It is installed in the shaft hole 13 and can rotate relatively. There is a through hole 21 in the rotating shaft 2. In this embodiment, the through hole 21 is designed as an L-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com