Bamboo board circular arc polishing and shaping mechanism

A technology of circular arc and bamboo board, which is applied in the field of bamboo board circular arc polishing and forming mechanism, can solve the problems of increasing working time, reducing efficiency, wasting time, etc., and achieves the effect of increasing working efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the present invention will be further explained below in conjunction with specific drawings.

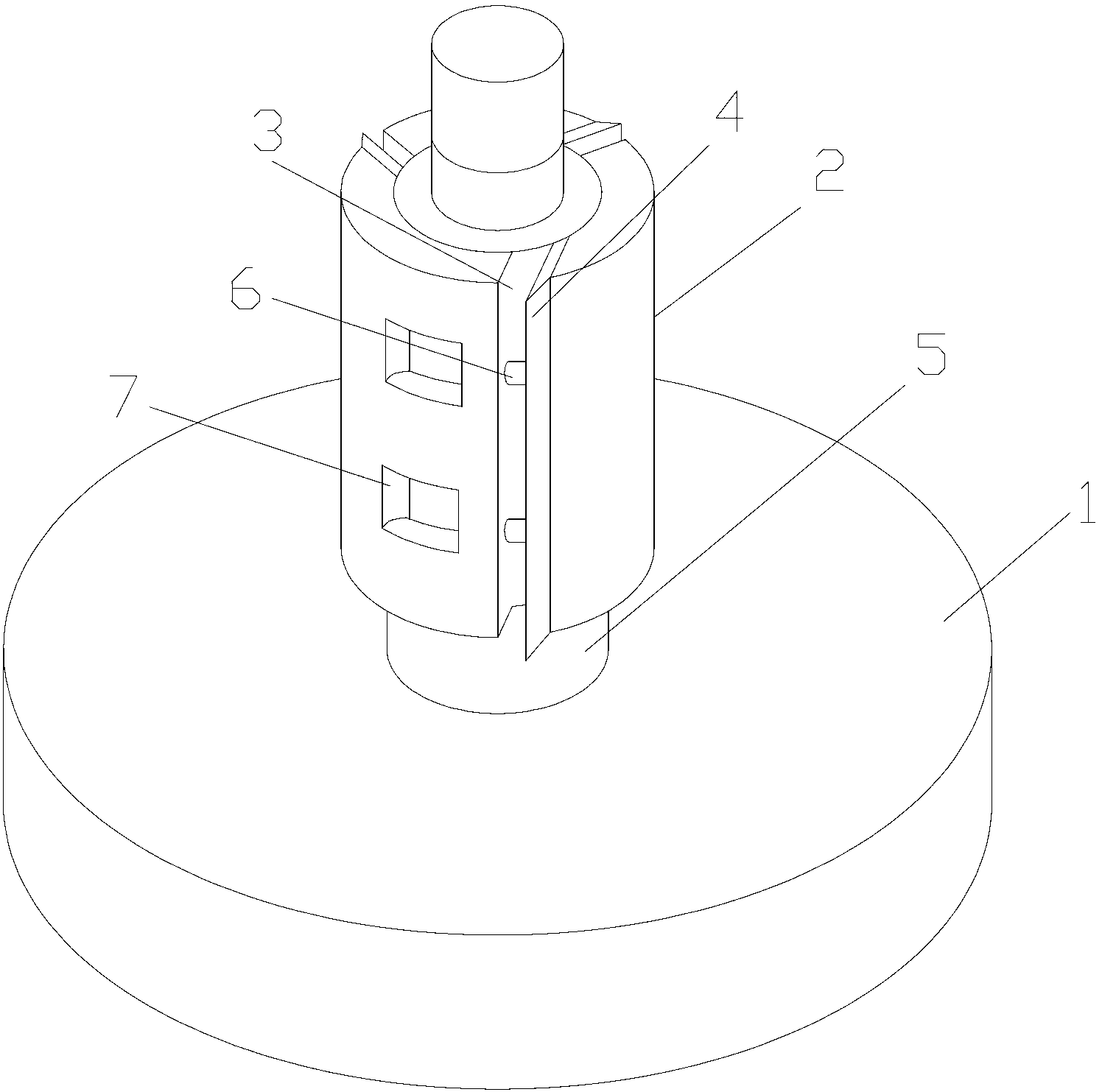

[0014] Such as figure 1 As shown, a bamboo board arc polishing and forming mechanism includes a base 1, a rotating knife shaft 2 and a rotating shaft 5. The rotating shaft 5 is installed in the center of the base 1, the rotating cutter shaft 2 is installed on the rotating shaft 5, and the rotating cutter shaft 2 is provided with a groove 3, a blade 4 is provided on the inner wall of the groove 3, a screw hole 7 is opened on the rotary knife shaft 2, and the blade is fixed on the inner wall of the groove 3 by a fastening screw 6. The diameter is 1cm-2cm larger than the diameter of the shaft 5.

[0015] The present invention is a bamboo board arc polishing and forming mechanism. When in use, the edge of the bamboo board is close to the rotating cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com