Mechanical vibration device of continuous casting machine

A technology of mechanical vibration and vibration device, applied in the field of vibration device, can solve the problems of high maintenance cost and high purchase cost, and achieve the effects of low maintenance cost, uniform vibration and low purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

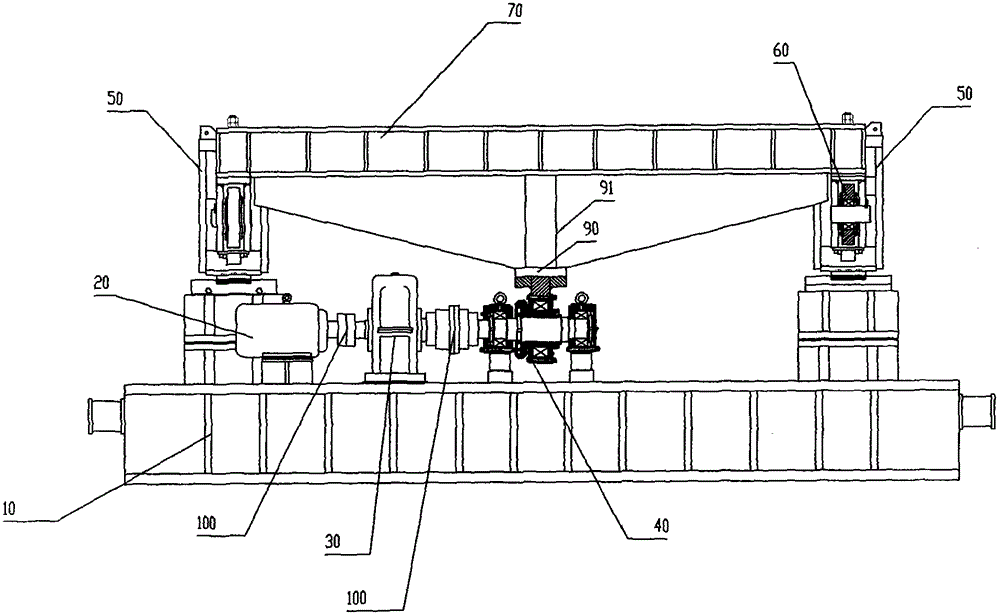

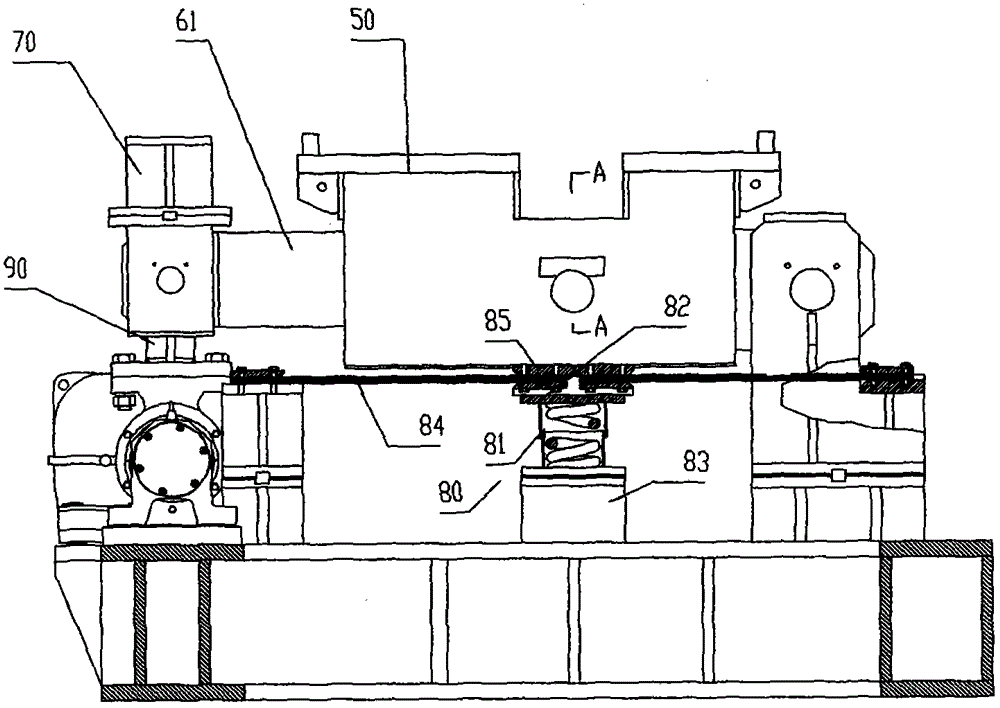

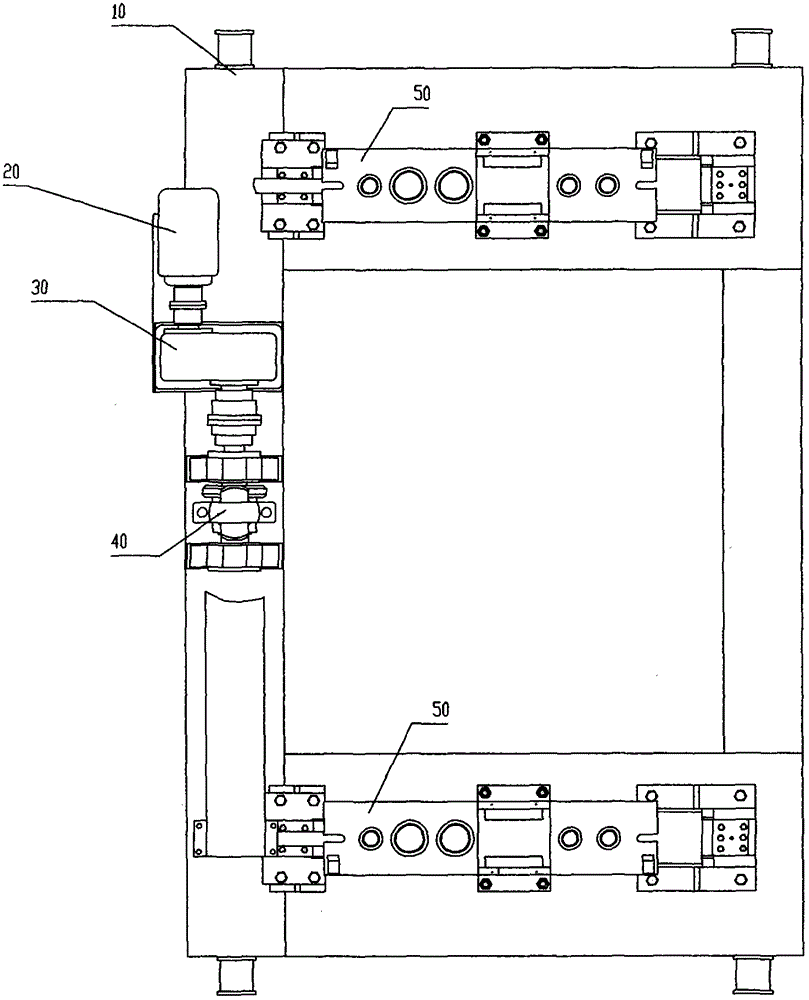

[0022] Please refer to figure 1 , figure 2 , image 3 The continuous casting machine mechanical vibration device of the present invention comprises a vibration device base 10, a motor 20 fixedly arranged on the vibration device base 10, a vibration reducer 30 and an eccentric wheel device 40, and the motor 20, the vibration reducer 30 and the eccentric wheel device 40 The bottom surface of the inverted trapezoidal push rod 90 is fixedly connected to the casing of the eccentric wheel device 40, and the two ends of the top surface are respectively fixedly connected to the connecting rod device 60 used to support the vibrating table frame 50. The left and right sides The vibrating table 50 is fixedly connected by a grid-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com