Gear rack type power steering gear automatic oil extraction device

A power steering gear and rack-type technology, applied in chemical instruments and methods, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problems of poor oil discharge effect and high oil discharge labor intensity, and reduce The production cost, equipment maintenance is convenient, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

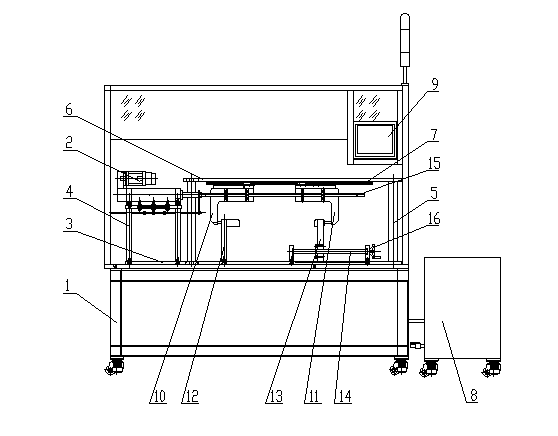

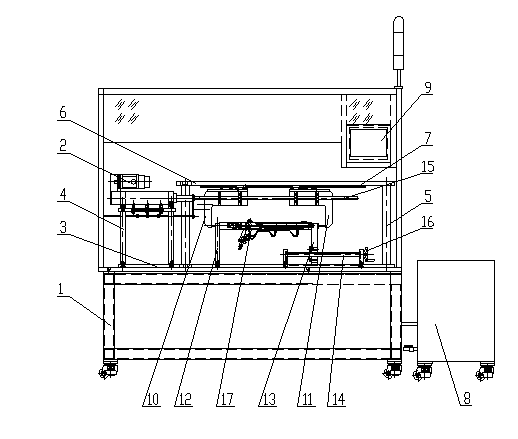

[0017] The rack and pinion type power steering gear automatic oil discharge device consists of a machine table (1), an electric cylinder (2), a bottom plate (3), an electric cylinder mounting frame (4), a column (5), a guide rail support plate (6), A linear guide rail (7) and a vacuum oil pump (8) are formed. A vacuum pump (8) is arranged on one side of the machine platform (1), a bottom plate (3) is arranged on the working surface of the machine platform (1), and a program control cabinet (9) is arranged on the machine platform (1) above the bottom plate. ). One end of the surface of the bottom plate (3) is equipped with the electric cylinder (2) through the electric cylinder mounting frame (4); the surface of the bottom plate (3) on the side of the electric cylinder mounting frame (4) is equipped with guide rails through symmetrically arranged columns (5) Support plate (6).

[0018] The lower surface of the guide rail support plate (6) is equipped with a linear guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com