Solid acid catalyst and use thereof

A solid acid catalyst and reaction technology, applied in physical/chemical process catalysts, fatty acid esterification, liquid carbon-containing fuels, etc., can solve problems such as harsh reaction conditions, achieve improved conversion rate, less dosage, and high catalytic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

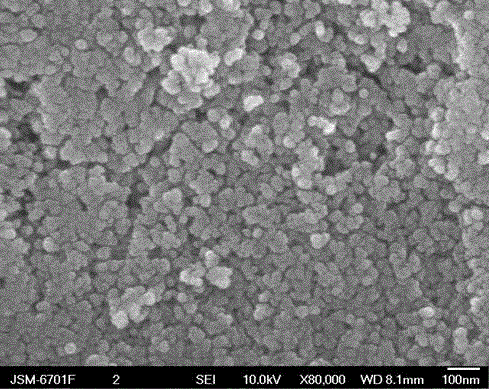

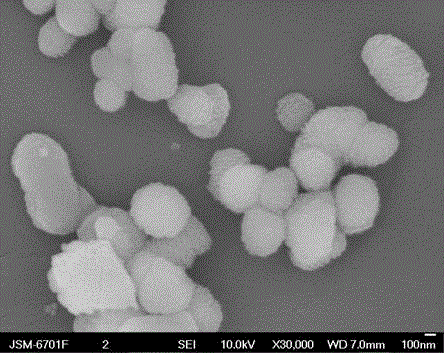

Image

Examples

Embodiment 1

[0023] The concrete preparation steps of 1# zirconium sulfate are as follows:

[0024] (1) Preparation of zirconium hydroxide powder:

[0025] 5 g zirconium oxychloride octahydrate (ZrOCl 2 ·8H 2 O) Dissolve in 100 mL of water, stir at room temperature, after the solution is clarified, add 25% ammonia water, adjust the pH value of the solution to 8, obtain a white precipitate of zirconium hydroxide, filter, wash with water until the filtrate does not contain chloride ions, Dry at 80 °C for 24 hours and grind into powder for later use.

[0026] (2) Preparation of zirconium sulfate raw powder:

[0027] Dissolve 2 g of polyvinylpyrrolidone (PVP) in 40 mL of ethylene glycol and stir at 60 °C. After the solution is clarified, add 0.5 g of the ground zirconium hydroxide powder, stir for 2 h, and add 0.2 M H 2 SO 4 The solution was 3 mL, stirred for 12 h, transferred to a polymerization kettle, put into an oven, and the temperature of the oven was set at 180 °C. After 12 hours, ...

Embodiment 2

[0031] The concrete preparation steps of 2# zirconium sulfate are as follows:

[0032] (1) Preparation of zirconium hydroxide powder:

[0033] With the preparation method of zirconium hydroxide powder among the embodiment 1.

[0034] (2) Preparation of zirconium sulfate raw powder:

[0035] Dissolve 2 g of polyvinylpyrrolidone (PVP) in 40 mL of ethylene glycol and stir at 60 °C. After the solution is clarified, add 1 g of the ground zirconium hydroxide powder, stir for 2 h, and add 0.2 M H 2 SO 4 The solution was 3 mL, stirred for 12 h, transferred to a polymerization kettle, put into an oven, and the temperature of the oven was set at 180 °C. After 12 hours, it was cooled to room temperature, filtered, washed and dried to obtain nano zirconium sulfate raw powder.

[0036] (3) Treatment of raw zirconium sulfate powder:

[0037] Nano zirconium sulfate raw powder was roasted in a muffle furnace with a heating rate of 1 °C / min and a constant temperature of 650 °C for 5 h to ...

Embodiment 3

[0039] The concrete preparation steps of 3# zirconium sulfate are as follows:

[0040] (1) Preparation of zirconium hydroxide powder:

[0041] With the preparation method of zirconium hydroxide powder among the embodiment 1.

[0042] (2) Preparation of zirconium sulfate raw powder:

[0043]Dissolve 2 g of polyvinylpyrrolidone (PVP) in 40 mL of ethylene glycol and stir at 60 °C. After the solution is clarified, add 2 g of the ground zirconium hydroxide powder, stir for 2 h, and add 0.2 M H 2 SO 4 The solution was 3 mL, stirred for 12 h, transferred to a polymerization kettle, put into an oven, and the temperature of the oven was set at 180 °C. After 12 hours, it was cooled to room temperature, filtered, washed and dried to obtain nano zirconium sulfate raw powder.

[0044] (3) Treatment of raw zirconium sulfate powder:

[0045] The zirconium sulfate raw powder was roasted in a muffle furnace with a heating rate of 1 °C / min and a constant temperature of 650 °C for 5 h to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com