Protective energy-saving pressure cooker

A pressure cooker and pot cover technology, which is applied to pressure cookers, special materials for cooking utensils, and shells/covers of cookers, etc., can solve the problems of large exposed area of metal surface, easy to be scalded or scalded, and a lot of heat loss, etc., to achieve The effects of speeding up the cooking process, shortening the cooking heating time, and slowing down the heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

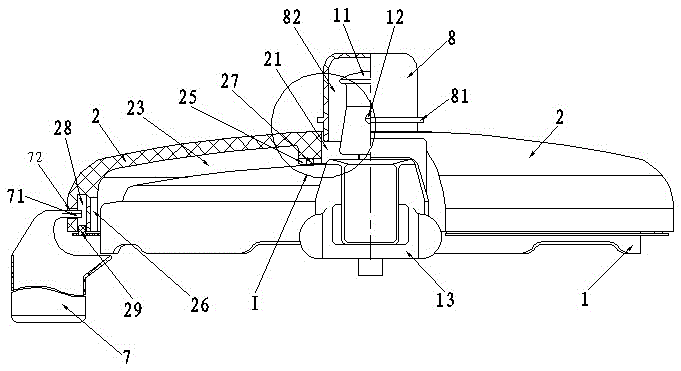

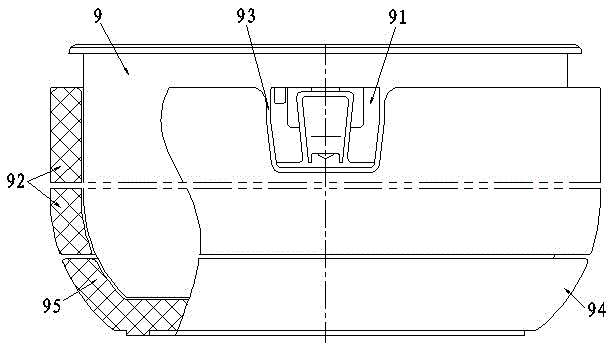

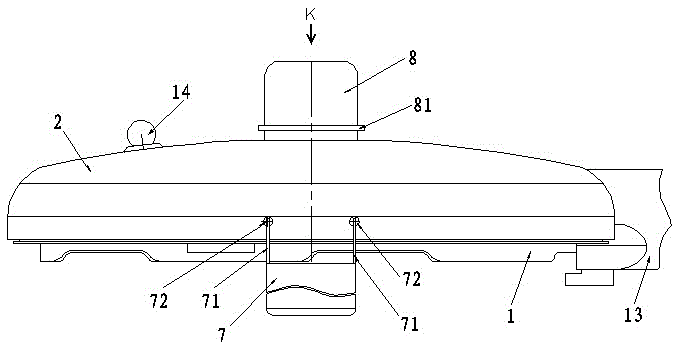

[0034] The protective energy-saving pressure cooker of the first embodiment of the present invention (see Figure 1-Figure 10 ), including a pot body 9 and a matching pot cover 1. Its structural feature is: the pot cover 1 is also provided with a shell 2 covering its surface; the shell 2 is made of a plastic material with suitable mechanical strength An integral structure made;

[0035] The above-mentioned housing 2 is provided with a valve position hole 21 for avoiding the pressure limiting valve bonnet 11. There is a suitable exhaust gap between the valve position hole 21 and the peripheral side of the bonnet 11, and the valve position hole 21 has a complete side. The lower end of the wall is tightly fitted on the corresponding position on the outer surface of the pot cover 1;

[0036] The above-mentioned shell 2 is provided with a relief groove 22 for avoiding the cover handle 13. The relief groove 22 has a complete side wall, and the lower end surface of the relief groove 22 is...

Embodiment 2

[0064] The protective energy-saving pressure cooker of the second embodiment of the present invention (see Picture 11 with Figure 14 ). In order to improve the function of the protective energy-saving pressure cooker of the present invention and make it easier to implement and apply, on the basis of the first embodiment of the present invention, the second embodiment of the present invention is further constructed with the following structure, the benefits of which will also be described later.

[0065] Further structure 1: The aforementioned shell cover 2 is made of foamed plastic material with suitable mechanical strength and operating temperature.

[0066] The shell cover 2 in this embodiment is made of foamed plastic material with suitable mechanical strength and suitable maximum use temperature, so as to achieve lower cost and more convenient use, and the pressure cooker can achieve better energy saving and heat preservation effects. The shell 2 in this embodiment is prefera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com