Preparation method and application of meat taste peptide

A meaty and deamidated technology, applied in vegetable protein processing and other directions, can solve the problems of high cost, low solubility and poor dispersion performance of enzyme preparations, and achieve the effect of high protein utilization and good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Wheat gluten protein powder and 9 times the mass ratio of water are prepared into a wheat gluten protein mixture, and succinic acid (accounting for 1% of the volume of the mixture) is used to deamidate it under 110oC humid heat for 1 hour, and the deamidation degree is 30 % wheat gluten protein suspension; add 0.3% acid protease based on the mass of wheat gluten protein powder, enzymolyze at 50°C for 30h, the degree of hydrolysis is 12.6%, and the protein recovery rate reaches 90%; inactivate the enzyme at 95°C for 15min, 8000r / m centrifugation for 20 minutes, the supernatant was passed through a 10,000Da ultrafiltration membrane to remove macromolecular polypeptides and proteins, concentrated and spray-dried into powder to obtain meat-flavored peptides, and the yield of meat-flavored peptides reached 80%.

Embodiment 2

[0039] Wheat gluten protein powder and 7 times the mass ratio of water are prepared into a wheat gluten protein mixture, which is placed in a water bath shaker at 50 oC for 20 hours with hydrochloric acid (accounting for 2% of the volume of the mixture) for deamidation treatment to obtain deamidation Wheat gluten protein suspension with a concentration of 35%; add 0.2% acid protease based on the mass of wheat gluten protein powder, enzymatically hydrolyze at 45°C for 24 hours, the degree of hydrolysis reaches 13%, and the protein recovery rate reaches 90%; Enzyme is inactivated at 85°C Centrifuge at 10,000r / m for 30min for 10min, pass the supernatant through a 10,000Da ultrafiltration membrane to remove macromolecular polypeptides and proteins, concentrate, spray and dry it into powder to obtain the meat-flavored peptide, and the yield of the meat-flavored peptide is about 81%.

Embodiment 3

[0041] Carry out in the same manner as in Embodiment 2, except that the hydrolyzate of deamidated wheat gluten protein is obtained by enzymatic hydrolysis at 55°C for 24 hours, the degree of hydrolysis is increased to 14.5%, the protein utilization rate reaches about 92%, and the peptide yield rate reaches About 85%, and the enzymatic hydrolyzate has typical meat flavor characteristics.

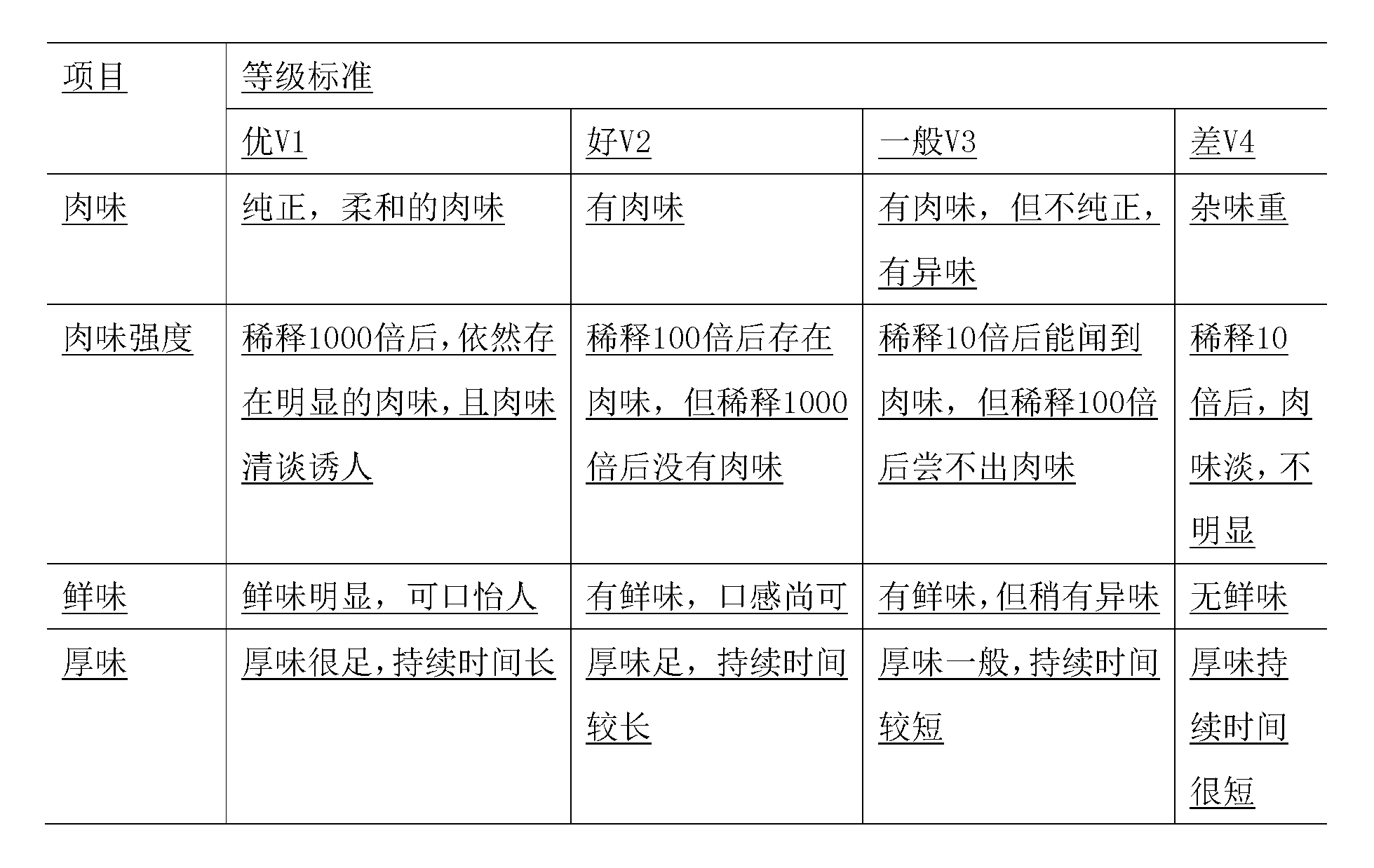

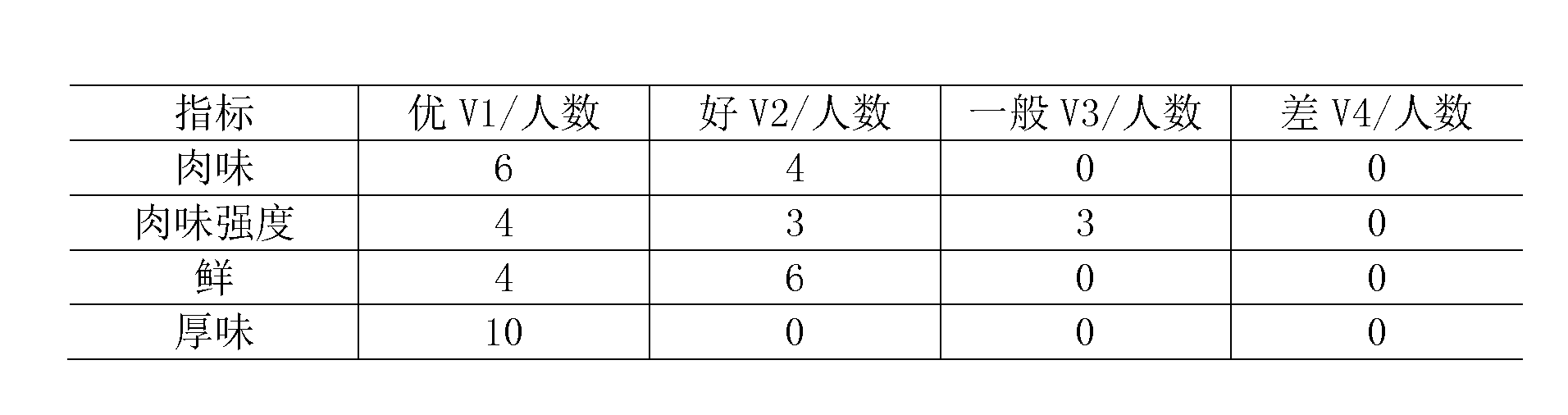

[0042] Table 3 is the sensory evaluation result of meat flavor peptide in embodiment 3

[0043] Table 3 Statistics of sensory evaluation results of meat-flavored peptides in Example 3

[0044]

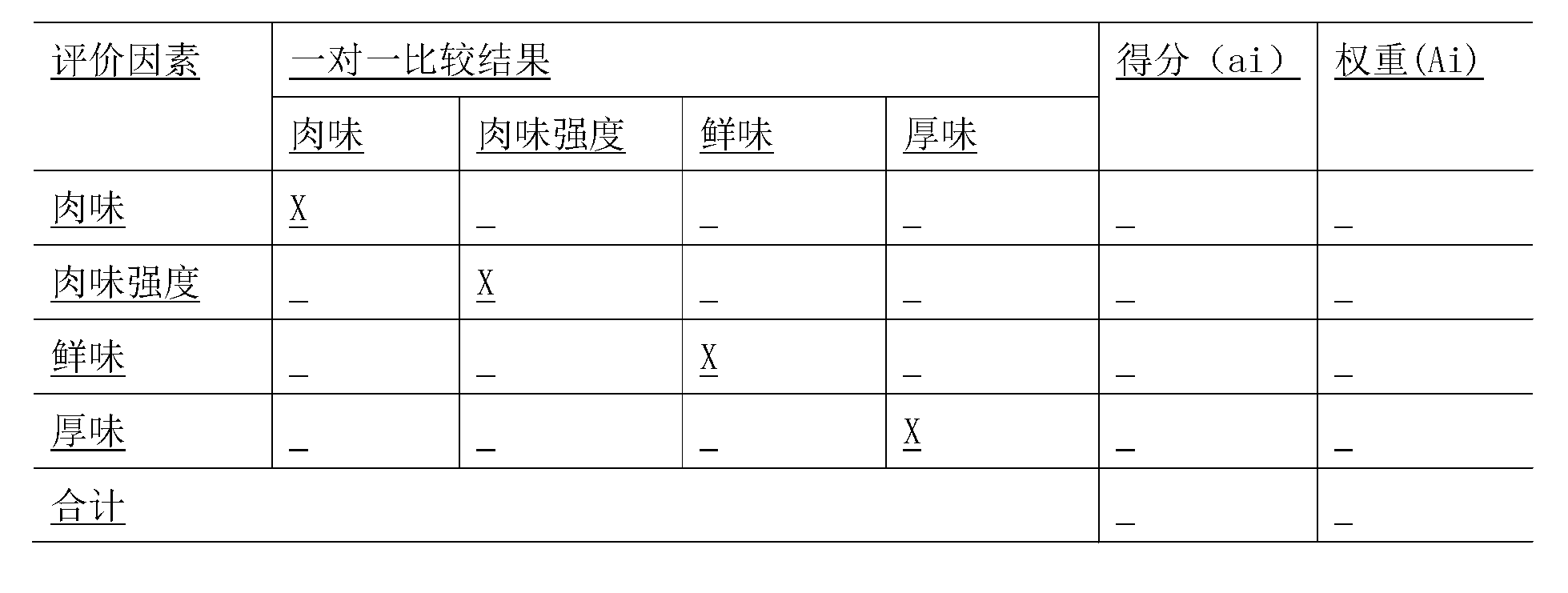

[0045] Get the fuzzy relationship matrix from the above table R = 0.6 0.4 0 0 0.4 0.3 0.3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com