Cotton picking device

A cotton and pedestal technology, applied in the fields of picking machines, agricultural machinery and implements, applications, etc., can solve the problems of wasting manpower, not easy to install, and waste a long time in maintenance, and achieves high work efficiency, simple installation, and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

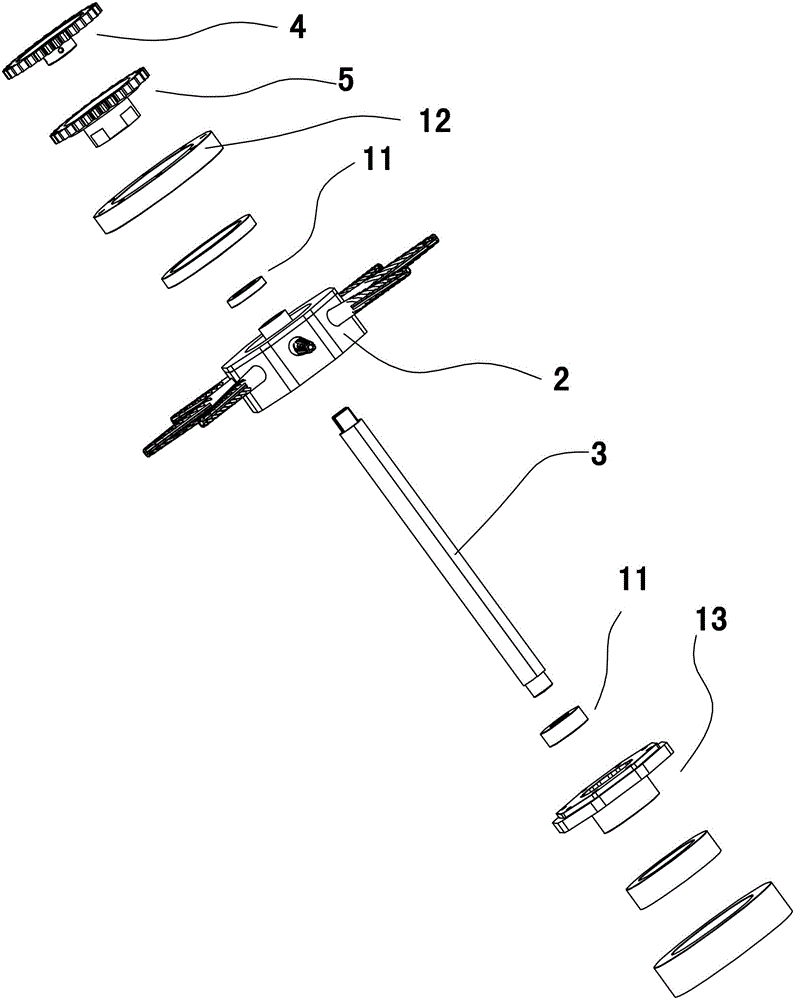

[0020] The cotton picking device includes a cotton picking mechanism 1 and a fixed frame; the fixed frame can be used in common use, and will not be described here, but the cotton picking mechanism 1 will be described here.

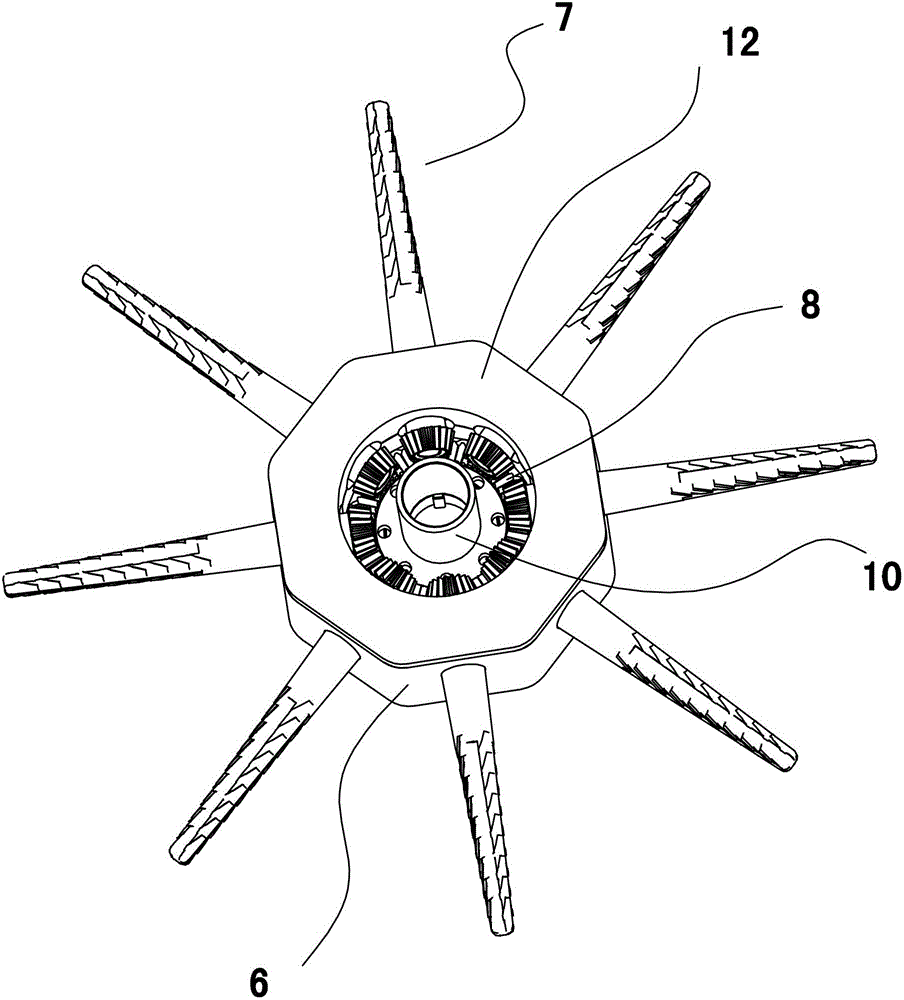

[0021] Please refer to Figure 1 to Figure 4 , the cotton picking mechanism 1 in the figure includes 12 picking units 2, 1 connecting rod 3, 1 first gear 4, 1 that can be spliced and stacked together through mutual convex and concave bayonets and fixed together longitudinally by screws A second gear 5 that can move independently of the first gear 4.

[0022] Each picking unit 2 includes a base 6 , eight wrapping parts 7 , and one engagement mechanism 8 that enables the wrapping parts 7 to freely rotate on the base 6 driven by the connecting rod 3 . The base 6 is a regular octagonal cylinder, each side is processed with a mounting hole 9 for installing the winding part 7, and the inside is hollow for installing the engaging mechanism 8, the sleeve 10, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com