Non-contact solenoid drive device of linear conducting liquid

A conductive liquid, electromagnetic drive technology, applied in the direction of electromechanical devices, electrical components, etc., can solve problems such as bad interaction and out of step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

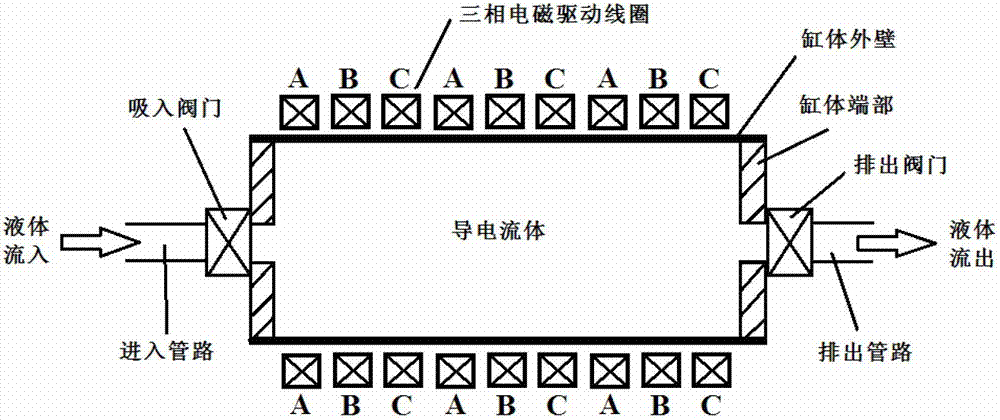

[0022] figure 1 Shown is an embodiment of the invention. The multi-phase electromagnetic drive coils in this embodiment adopt three-phase electromagnetic drive coils.

[0023] The linear conductive liquid non-contact drive device of the embodiment of the present invention is composed of a cylindrical cylinder, a suction valve, a discharge valve, a three-phase electromagnetic drive coil, a three-phase AC power supply, a three-phase switch and a three-phase protection device. Its structure is as follows figure 1 shown. Such as figure 1As shown, the cylinder body of the linear conductive liquid non-contact driving device is a hollow circular cylinder, and the outer wall of the cylinder body is made of non-magnetic stainless steel sheet. The two ends of the cylinder body are made of non-magnetic stainless steel plates with a certain thickness, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com