Miniature motor and cooling fan having the same

A micro-motor and cooling fan technology, applied to synchronous motors with stationary armatures and rotating magnets, electric components, non-variable pumps, etc., can solve the problem of poor combination stability, easy breakage or damage, and convenient assembly Poor performance and other problems, to achieve the effect of improving the convenience of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

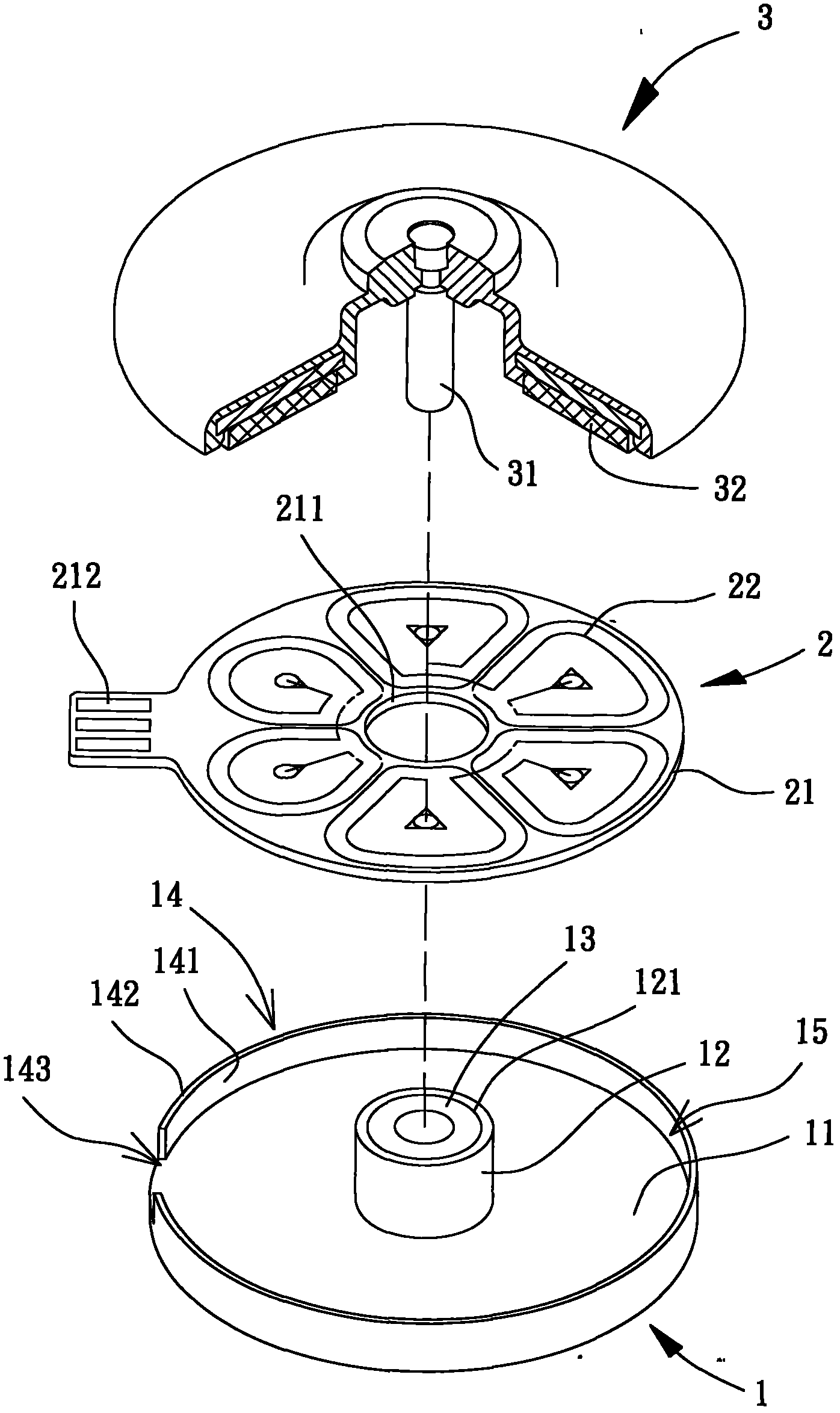

[0063] As shown in the figure, in order to make the above and other objects, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention are specifically cited below, and in conjunction with the accompanying drawings, the detailed description is as follows:

[0064] Please refer to image 3 As shown, the micro motor of the present invention at least includes a base 1 , a stator coil assembly 2 and a rotating member 3 . The base 1 can be combined with the stator coil group 2, and the stator coil group 2 can be connected with an external power supply or drive circuit. 3 rotation actions.

[0065] The base 1 has a coupling surface 11, and the coupling surface 11 is provided with a pivot portion 12, which can be designed in various structures capable of pivotally coupling the rotating member 3; in this embodiment, the pivot The connecting portion 12 is a shaft tube, an opening 121 is formed at an end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com