Biological environment-friendly expansion-drop combination energy dissipater

An eco-environment-friendly technology, applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems that the bottom plate is threatened by the vertical shaft vortex, shorten the length of the stilling pool, etc., to improve the downstream ecological environment, the atomization range is small, Reduce the effect of twirling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

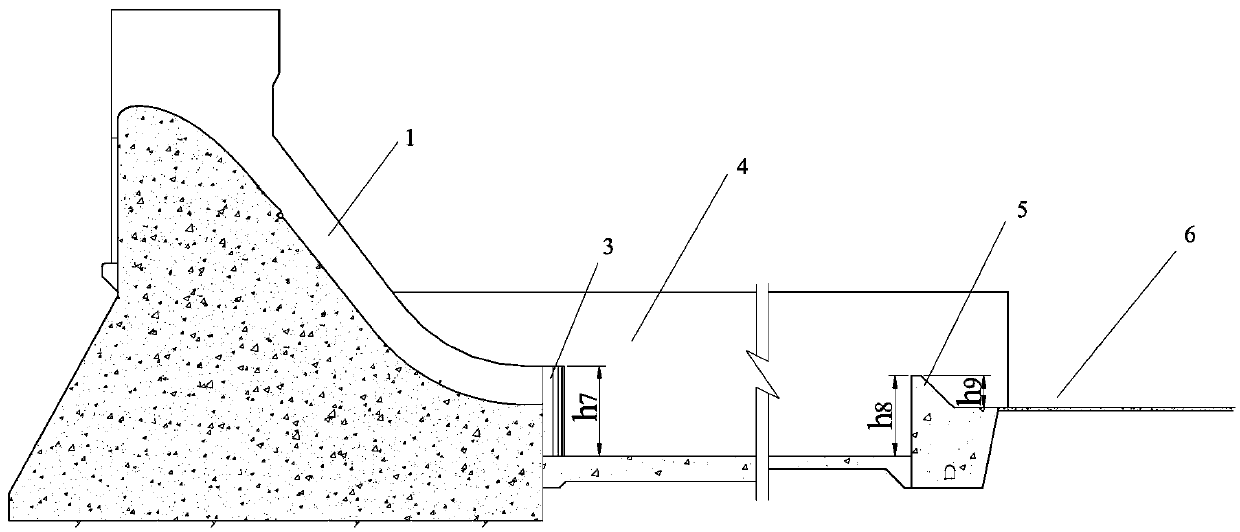

[0044] The structure of the eco-environmentally friendly drop-expansion combined energy dissipator in this embodiment is as follows: figure 1 , figure 2 , Figure 5 , Figure 9 , Figure 11 with Figure 13 As shown, its structural composition includes seven high sill discharge troughs 1, seven low sill sill discharge troughs 2, solid water carrying sills 10, seven chute partition walls 7, stilling pools 4, and stilling pool tail sills 5 , Downstream apron 6. It should be noted that the number of the above-mentioned high sill drain grooves and low sill drain grooves is only exemplary, and should not be construed as limiting, and the number can be two, three or any number.

[0045] Among them: the high sill discharge tank 1 is a non-pressurized horizontal outflow in the form of splits, such as Figure 5 shown; each drain slot 1 width d 2 = 12m, the thickness of the chute partition wall is 7 d 3 = 4m. The low-sill discharge trough and the high-sill discharge trough are ...

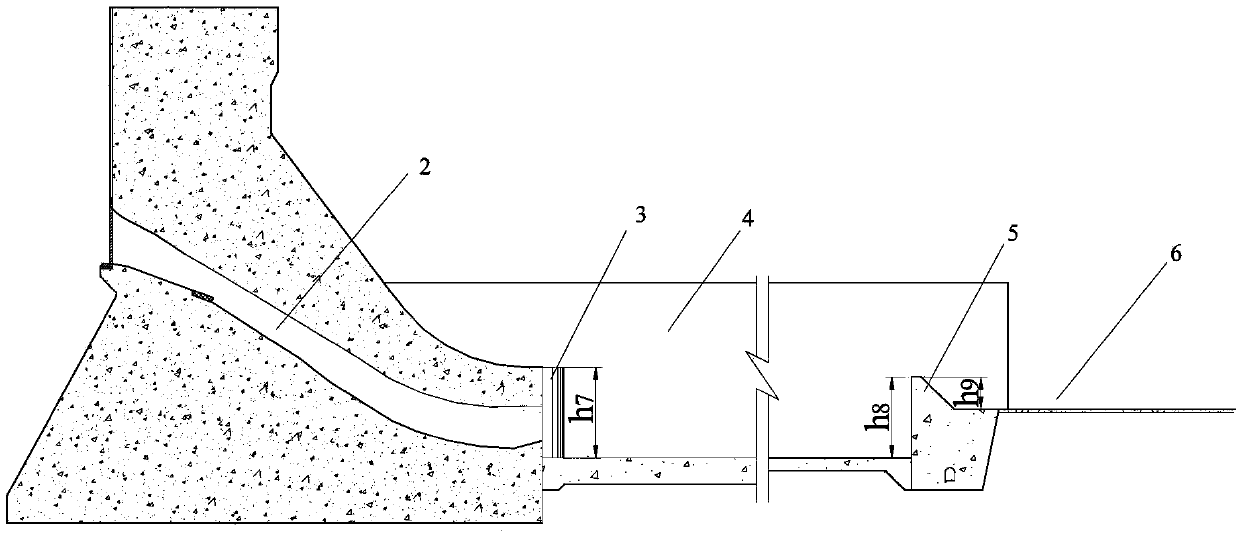

Embodiment 2

[0047] The structure of the eco-environmentally friendly drop-expansion combined energy dissipator in this embodiment is as follows: figure 1 , figure 2 , Image 6 , Figure 9 , Figure 11 with Figure 13 As shown, the structural composition includes seven high sill discharge troughs 1, seven low sill sill discharge troughs 2, solid water carrying sills 10, seven chute partition walls 7, stilling pools 4, stilling pool tail sills 5, Downstream armor 6. Among them: the high-sill discharge trough is in the form of splits without pressure outflow, and the outlet of the high-sill discharge trough is set at a depression angle of 1:10 from the end of the overflow dam surface, as shown in Image 6 Shown; each high sill 1 width d 2 = 12m, the thickness of the chute partition wall is 7 d 3 =4m, 1:10 depression angle section 9 length L 6 = 8m. The low-sill discharge trough and the high-sill discharge trough are arranged in parallel in the same way, and they are pressurized mul...

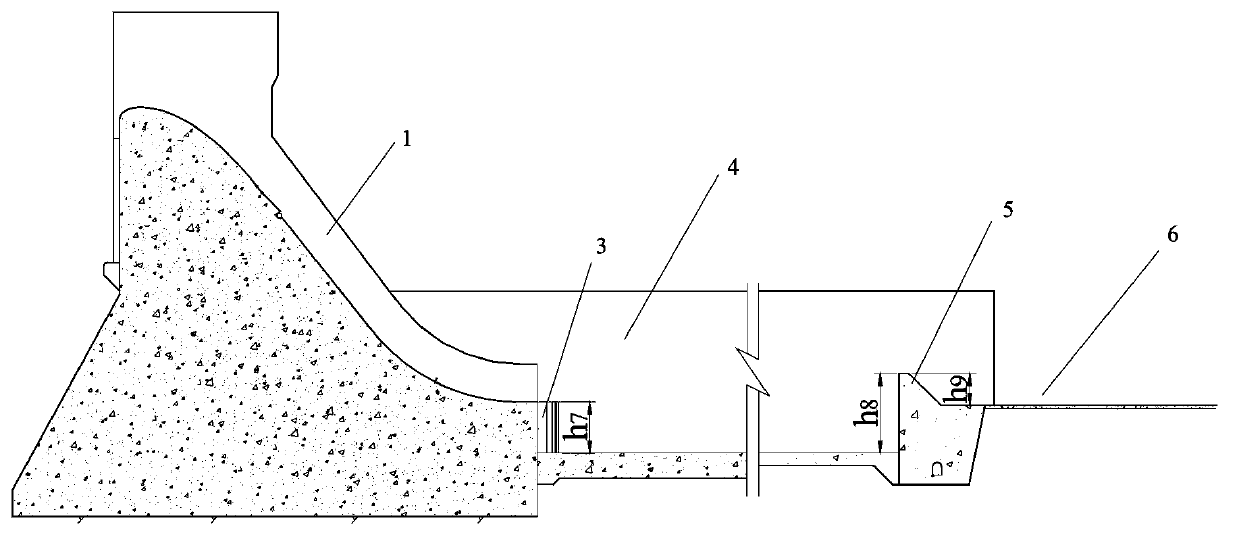

Embodiment 3

[0049] The structure of the eco-environment friendly drop-diffusion bottom flow energy dissipator in this embodiment is as follows: figure 1 , figure 2 , Figure 5 , Figure 10 , Figure 11 , Figure 14 with Figure 15 As shown, the structural composition includes seven high sill discharge troughs 1, seven low sill sill discharge troughs 2, tooth grid type water carrying sills 11, seven chute partition walls 7, stilling pool 4, and stilling pool tail sill 5 , Downstream apron 6. Among them: the high sill discharge trough is a non-pressurized horizontal outflow in the form of splits, such as Figure 5 Shown; each high sill 1 width d 2 = 12m, the thickness of the chute partition wall is 7 d 3 = 4m. The low sill discharge trough 2 and the high sill discharge trough 1 are arranged in parallel in the same arrangement, both of which are pressurized and multi-strand outflows, such as Figure 10 As shown, each low sill chute is 2 wide d 1 = 12m, the thickness of the chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com