Flechage knitting method, and knitted fabric

A knitted fabric and needle bed technology, which is applied in the field of knitted fabrics, can solve the problems such as the limit of the number of foldback knitting and the difficulty of knitting, and achieve the effect of improving the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0037] figure 1 The shown knitted fabric 100 is a tubular knitted fabric including a front body 20 and a back body 30 , and a collar 40 is formed in a neckline 41 serving as a collar hole. When knitting this knitwear 100 , first, the front body 20 and the back body 30 are knitted up to the position 50 of the lower end of the collar portion 40 . Then, the front body 20 and the back body 30 are knitted by C-shaped foldback knitting to form the outline of the neckline 41 , and finally the collar 40 is knitted continuously with the stitches constituting the neckline 41 . The foldback knitting of the present invention is used to form the outline of the neckline portion 41 .

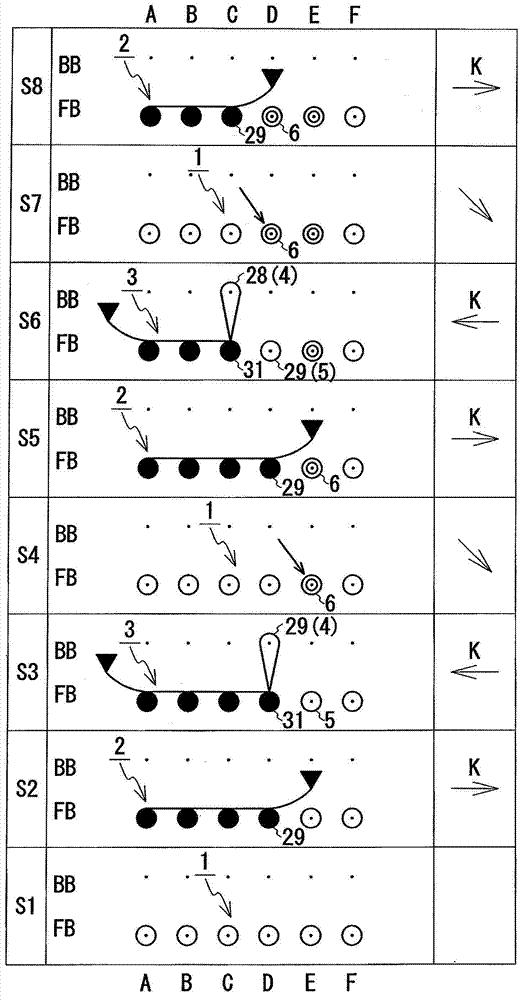

[0038] figure 2 is for weaving figure 1 A knitting process diagram of the neckline portion 41 on the right side of the front body 20 (left side in the drawing). in the figure 2 The "S+Number" recorded in the left column indicates the number of the knitting process, the left and right arrows with "K" rec...

Embodiment approach 2

[0053] In the embodiment with reference to the drawings, the needle widening was performed in the backward knitting, but the needle widening may be performed in the forward knitting. For example, in figure 2 In S2, the knitting needle D of the FB can be used for widening, so that the widening stitch completed at this time (in S1, the stitch hooked on the knitting needle D of the FB) overlaps with the stitch of the knitting needle E of the FB.

[0054] In addition, it is also possible to use both the forward knitting and the returning knitting to perform the needle widening. For example, when performing outward knitting in S2, you can use the knitting needle D of the FB to perform the widening stitch (the stitch hooked on the knitting needle D of the FB in S1) to overlap the stitch of the knitting needle E of the FB Thereafter, return knitting is performed starting from the position of the knitting needle C of the FB. The widening stitch formed in the backward knitting (the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com