Chain tension checking device

A technology for checking device and tension, which is applied in the direction of transportation, packaging, conveyors, etc. It can solve problems such as insufficient chain tension, running chain, and increased chain sag, so as to prolong the service life of the equipment and solve the problem of chain detachment. chain, to avoid the effect of chain off-chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

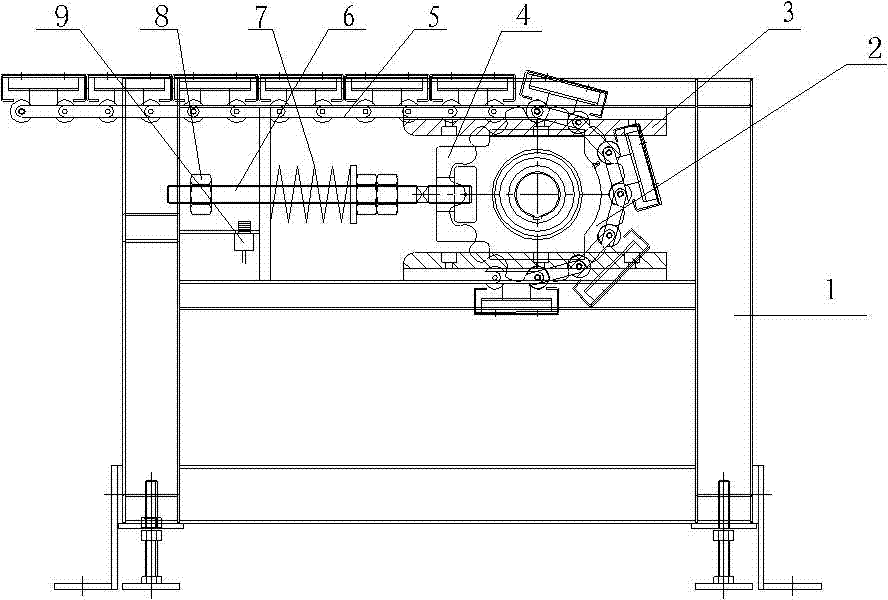

[0008] See figure 1 , the present invention comprises a frame 1 and a sprocket 2, the frame 1 is provided with a slide rail 3, the axle of the sprocket 2 is mounted on a slide block 4, the slide block 4 is mounted on the slide rail 3, the slide block 4 is connected to a screw rod 6, and the screw rod 6 After the spring 7 is set, the frame 1 is passed through, and an induction nut 8 is installed at the end thereof, and a sensor 9 is installed on the frame 1 under the induction nut 8 .

[0009] Once the chain 5 of the chain conveyor is stretched, the spring 7 will simultaneously push the screw 6 and the sprocket 2 outwards to ensure the tension of the chain 5 . When the stretching of the chain 5 reaches a certain amount, when the induction nut 8 on the screw rod 6 approaches the position of the sensor 9, the sensor 9 senses the proximity of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com