Railway tank car pull pillow core plate structure

A technology of plate structure and tank car, which is applied to railway car body parts, tank cars, transportation passenger cars, etc., can solve cracking, the under-pillow middle cover plate and the installation surface cannot be completely adhered, and the under-pillar middle cover plate and the upper center plate are affected. In order to achieve the effect of continuous structure, flush surface and strong anti-fatigue ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

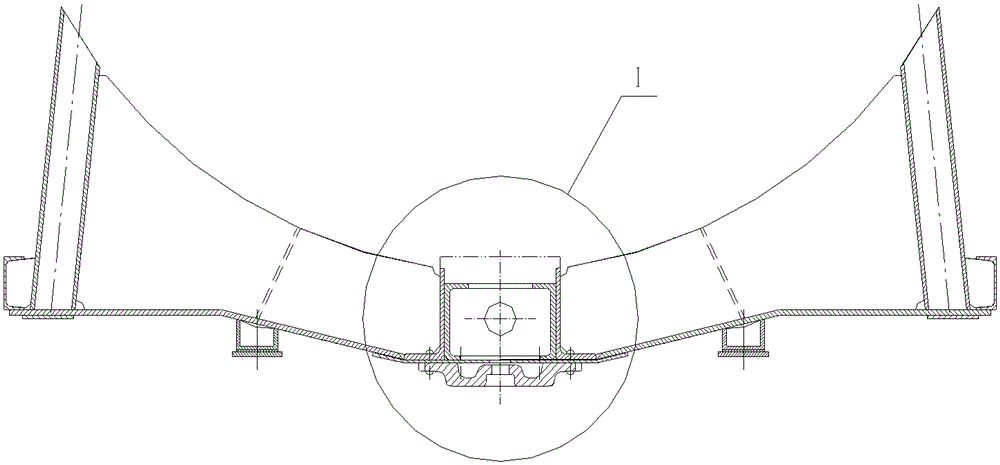

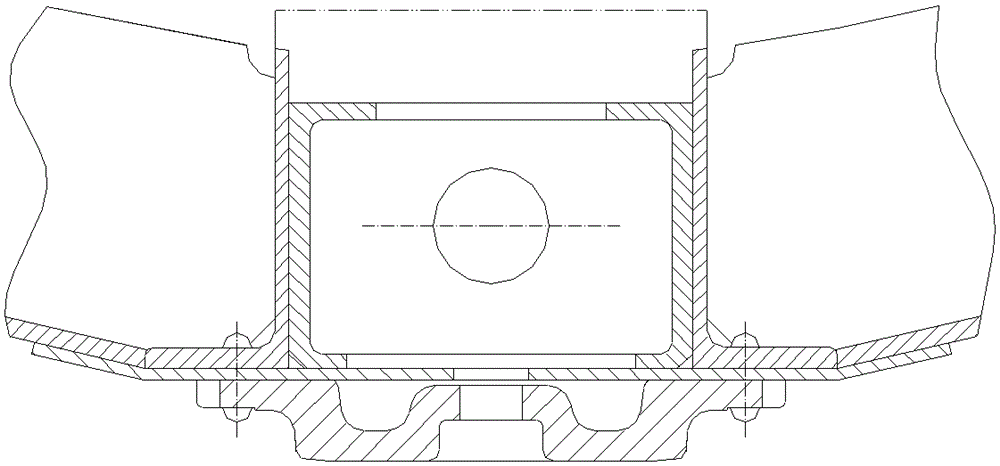

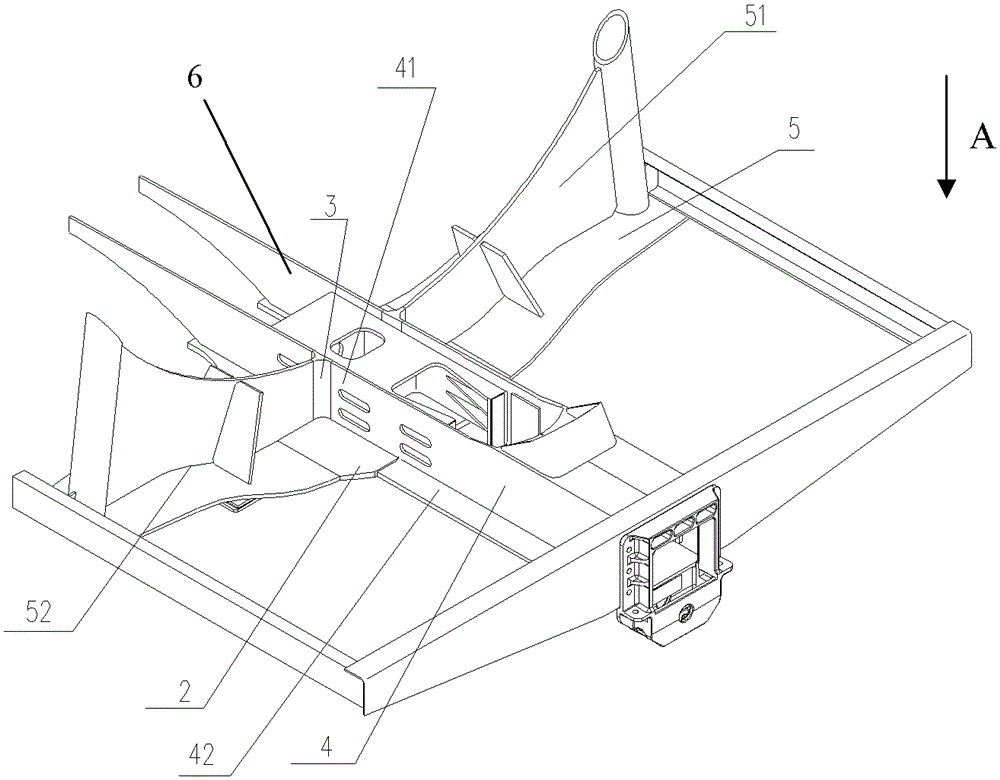

[0025] see Figure 2-Figure 4 , the present invention proposes a center disc structure for a railway tank car traction pillow. The center disc structure is composed of an upper center disc 1 and a center disc seat 2. The traction pillow mainly includes a T-shaped connector 3, a traction beam 4, a corbel 5, and a traction beam Tail plate 6, draw beam tail plate 6 is connected with draw beam 4. The traction beam 4, the T-shaped connector 3, the traction beam tail plate 6 and the corbel 5 are left and right pieces; the center plate structure is arranged between the two traction beams; The cover plate 52 ; the traction beam 4 includes a vertical traction beam web 41 and a horizontal traction beam lower airfoil 42 . The web 41 of the traction beam is longer than the lower airfoil 42 of the traction beam, and is butt-connected with one end of the T-shaped connector 3 , and the other end of the T-shaped connector 3 is butted-connected with the tail plate 6 of the traction beam, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com