Traction and bolster center plate structure of railway tank car

A disc structure and tank car technology, which is applied in the direction of railway car body parts, tank cars, transport passenger cars, etc., can solve the problem that the middle cover under the pillow and the installation surface cannot be completely adhered to, cracked, and the middle cover under the pillow and the upper center plate are damaged. To avoid problems such as poor force conditions, achieve the effect of smooth surface, continuous structure and strong fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

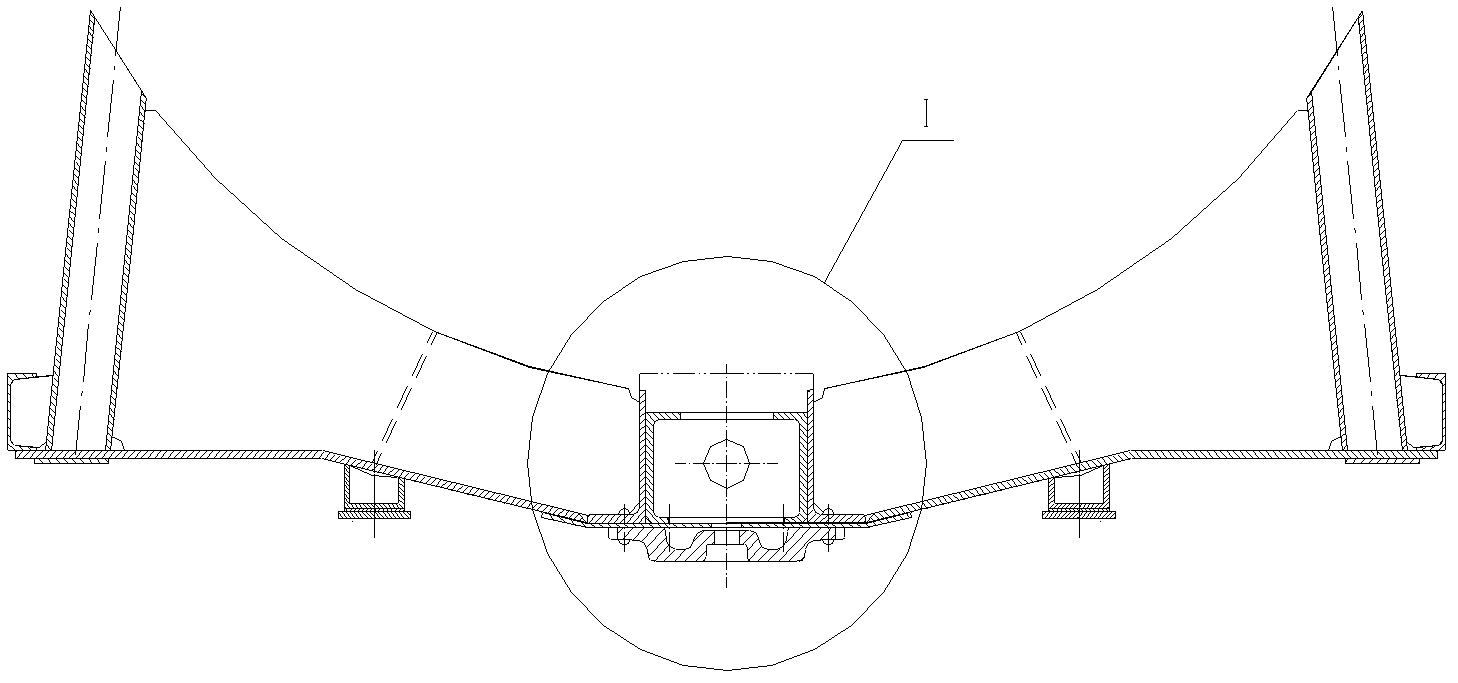

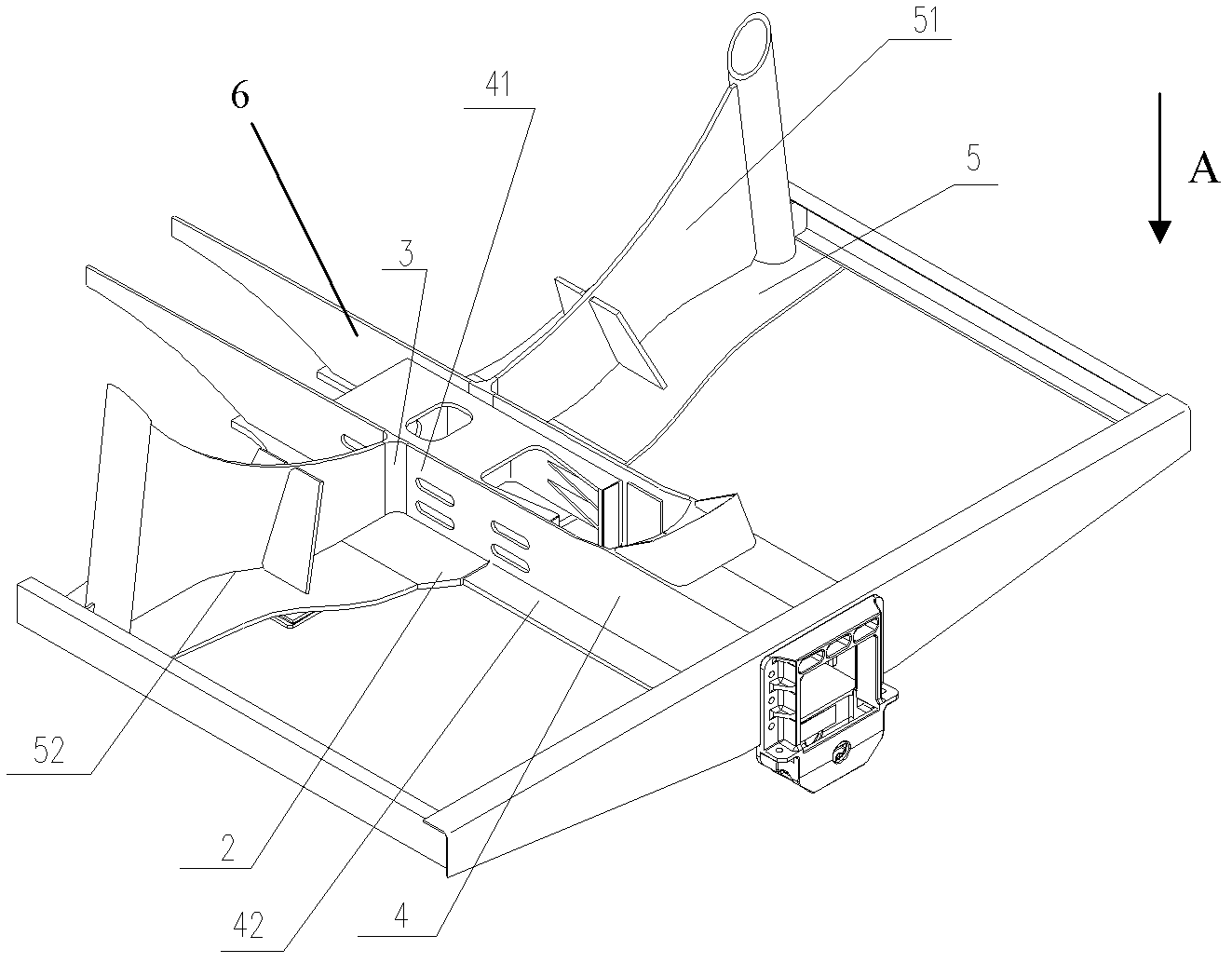

[0025] see Figure 2-Figure 4 , the present invention proposes a core plate structure of a railway tank car pulling pillow. The core plate structure is composed of an upper center plate 1 and a core plate seat 2. The pulling pillow mainly includes a T-shaped connecting piece 3, a traction beam 4, a bolster beam 5, and a traction beam. Tail plate 6, traction beam The tail plate 6 is connected with the traction beam 4. The traction beam 4, the T-shaped connector 3, the traction beam tail plate 6 and the bolster 5 are left and right; the core plate structure is arranged between the two traction beams; the bolster 5 includes the bolster web 51 and the bolster lower Cover plate 52; the traction beam 4 includes a vertical traction beam web 41 and a horizontal traction beam lower wing surface 42. The traction beam web 41 is longer than the lower wing surface 42 of the traction beam, and is connected with one end of the T-shaped connector 3, the other end of the T-shaped connector 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com