Magnetic suspension vehicle travelling unit in traction linear motor

A linear motor and magnetic levitation technology, applied in the direction of electric traction, electric vehicles, vehicle parts, etc., can solve the problems of reducing natural air cooling heat dissipation efficiency, reducing motor efficiency, increasing motor current, etc., to achieve the benefit of natural air cooling heat dissipation, The effect of improving heat dissipation efficiency and improving traction power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

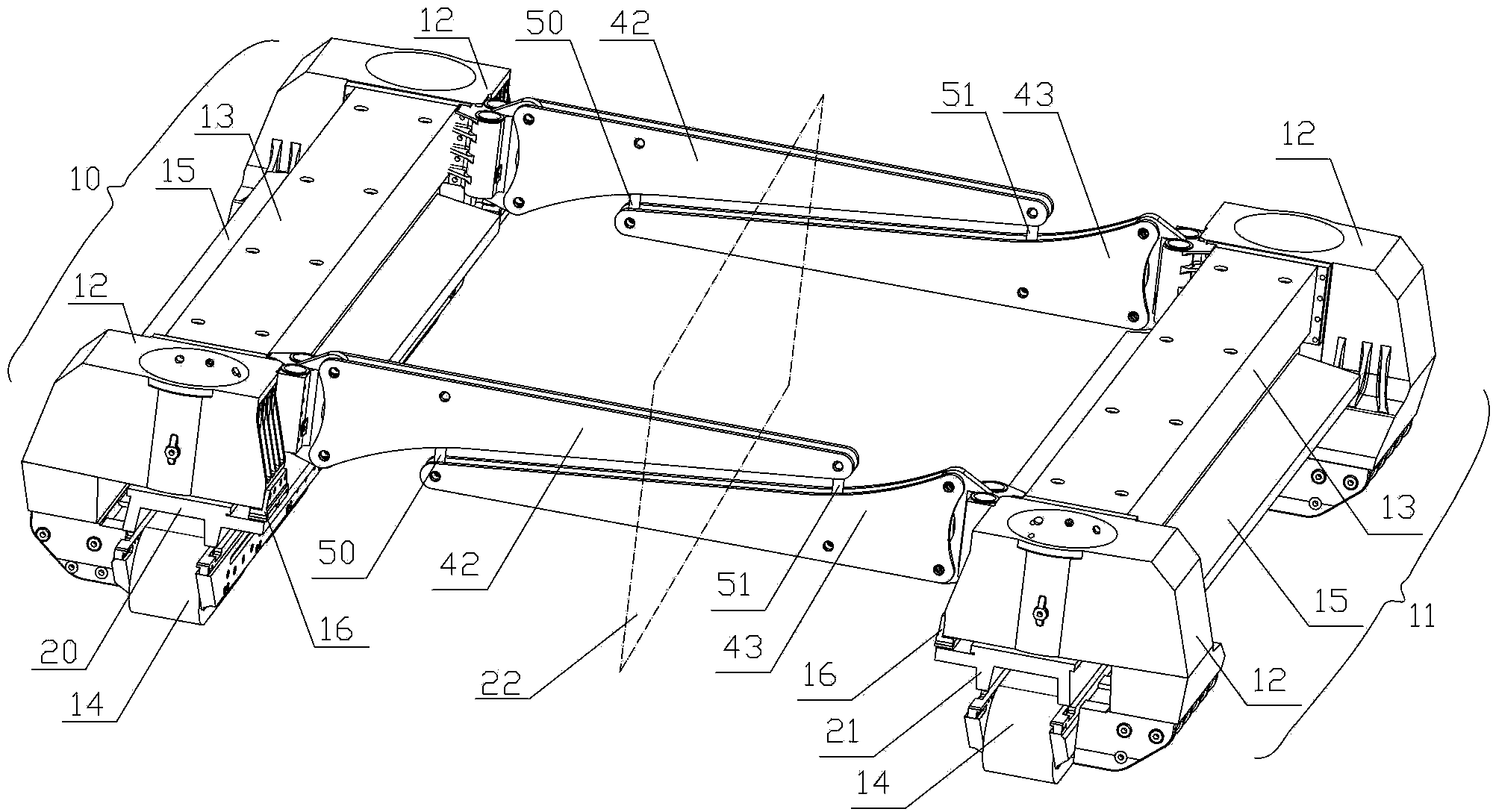

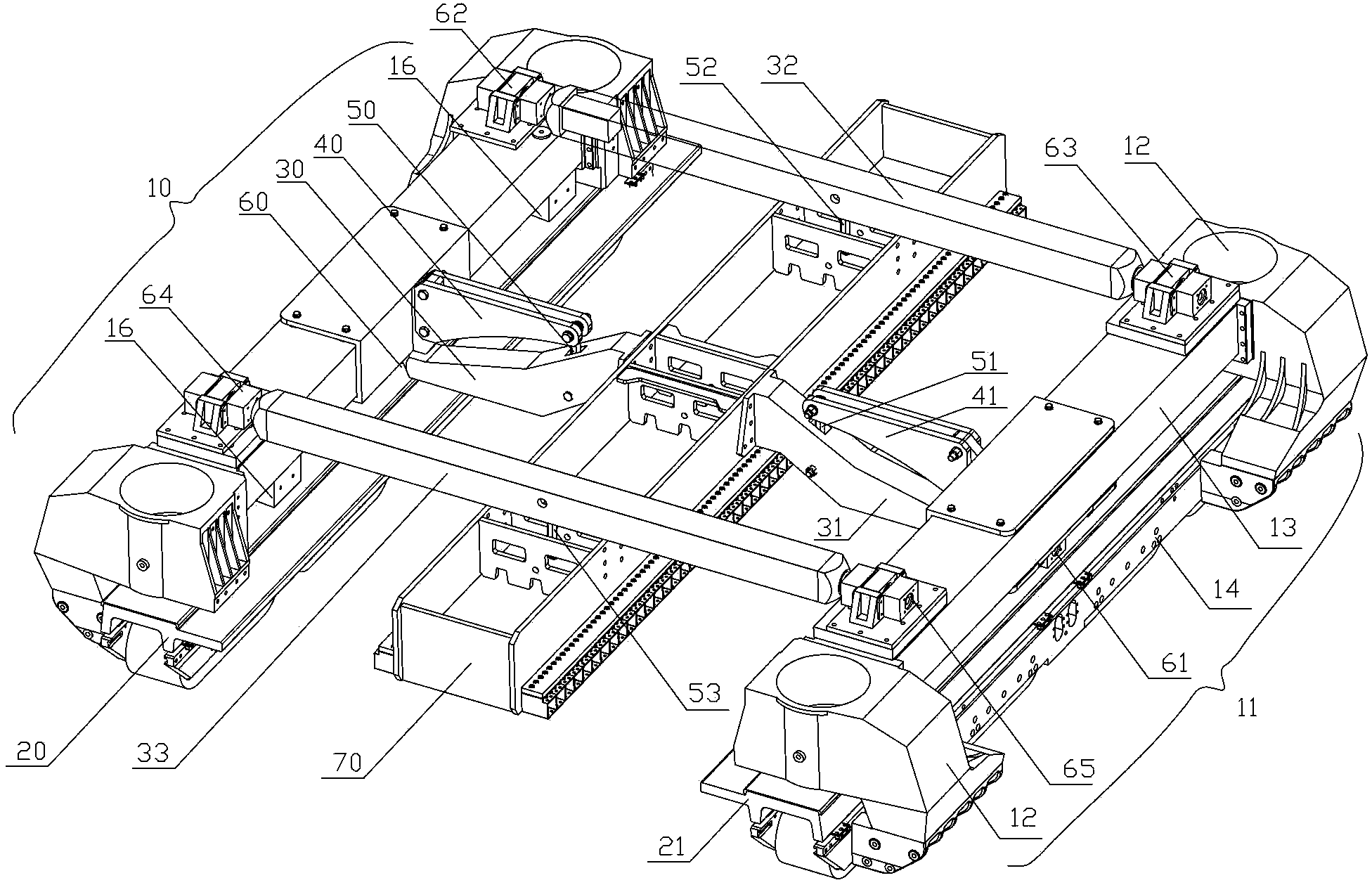

[0032] image 3 It is a three-dimensional structural diagram of the walking unit of the present invention; as image 3 As shown, the present invention is composed of two independent suspension modules, a traction linear motor 70, two beams, four sets of beam ball hinge linear combined bearings, two motor suspension rods and a set of anti-roll mechanism. Similar to the existing running unit, the left suspension module 10 of the present invention is arranged on the left side of the track, and the right suspension module 11 is arranged on the right side of the track. Different from the existing running unit, the traction linear motor 70 is arranged between the left suspension module 10 and the right suspension module 11 to reduce the limiting factor of the motor size. Traction linear motor 70 is placed on the middle part of running unit, is hoisted on the middle part of front end crossbeam 32 by front motor suspender 52, is hoisted on the middle part of rear end crossbeam 33 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com