Welding fixture of vehicle rear composition device

A combined device and welding fixture technology, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of inconvenient adjustment, unsafe and reliable clamping, and inaccurate positioning, and achieve convenient and accurate adjustment methods, clamping Safe and reliable, accurate positioning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

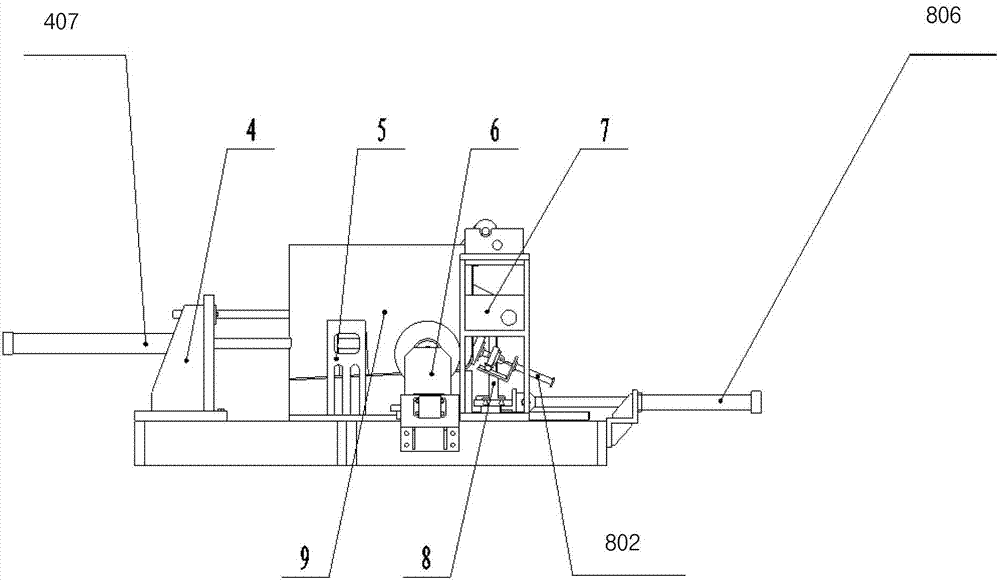

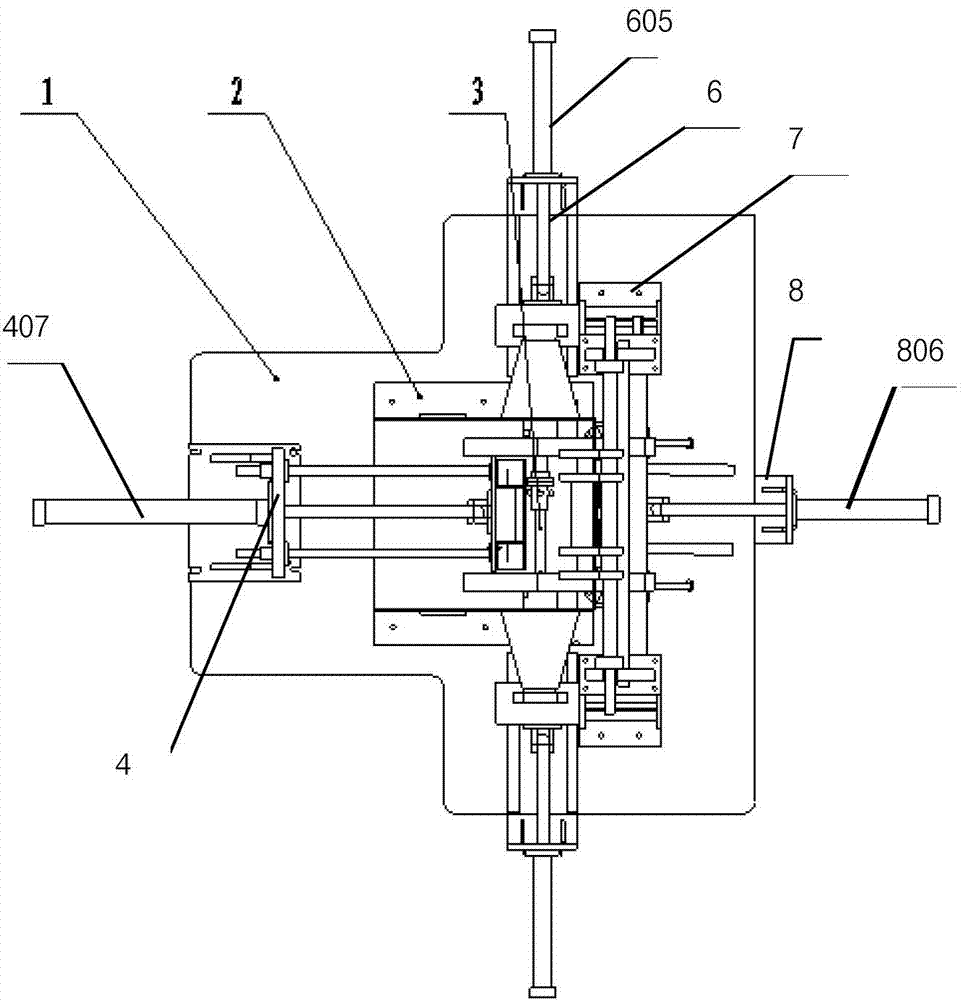

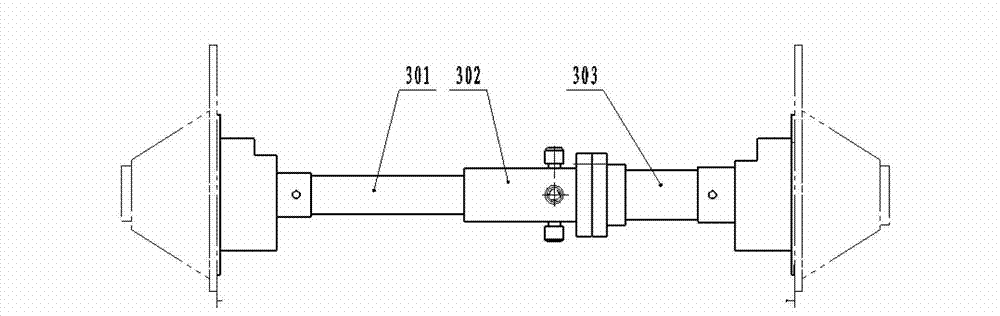

[0033] Inclined 8? Backing plate 2 is fixedly connected with support 1, mandrel clamping mechanism 3 is placed on support 2, mandrel clamping mechanism and long axis 301 are plugged with left induction pulley sleeve 310, short axis 303 is connected with right The induction wheel sleeve 309 is plugged in, the tail support seat clamping mechanism 4 is fixedly connected with the support 1 through the fixed seat 401, the inserting plate 5 is fixedly connected with the support 1, and the induction wheel clamping mechanism 6 is connected with the support through the oil cylinder connection seat 1 601. The seat 1 is fixedly connected, the positioning shaft 604 of the induction wheel clamping mechanism is plugged into the left induction wheel sleeve and the right induction wheel sleeve respectively, the pull arm pulling ear clamping mechanism 7 is fixedly connected with the support 1 through the bracket 701, and the tail supports Ring clamping mechanism 8 is fixedly connected with supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com