Consistent production method for insole

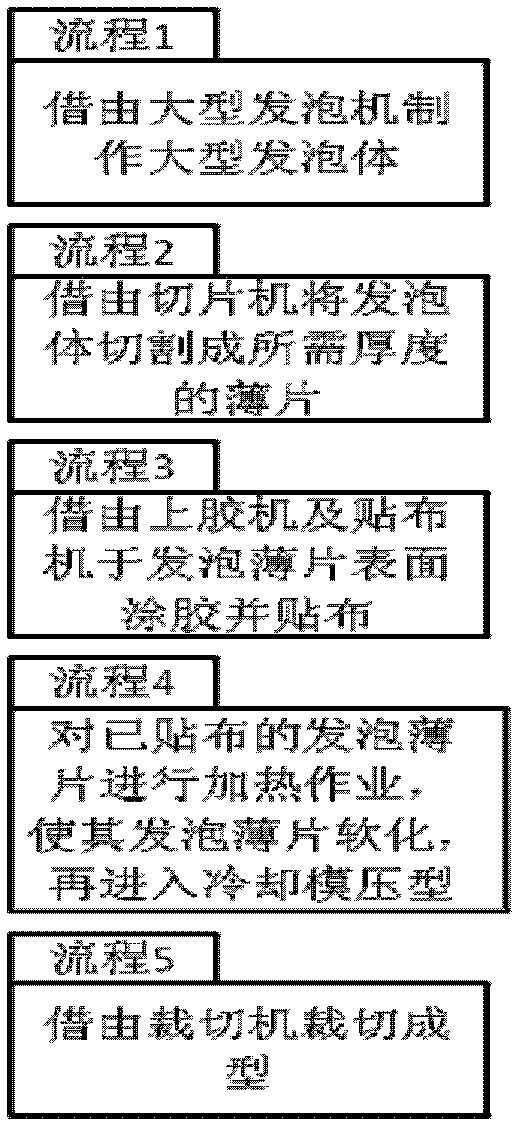

A manufacturing method and technology of insoles, applied in insoles, chemical instruments and methods, footwear, etc., can solve the problems of unsuitability for industrial utilization, cost of a large amount of manpower and machine operation, difficulty in increasing the speed and production volume of the production process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

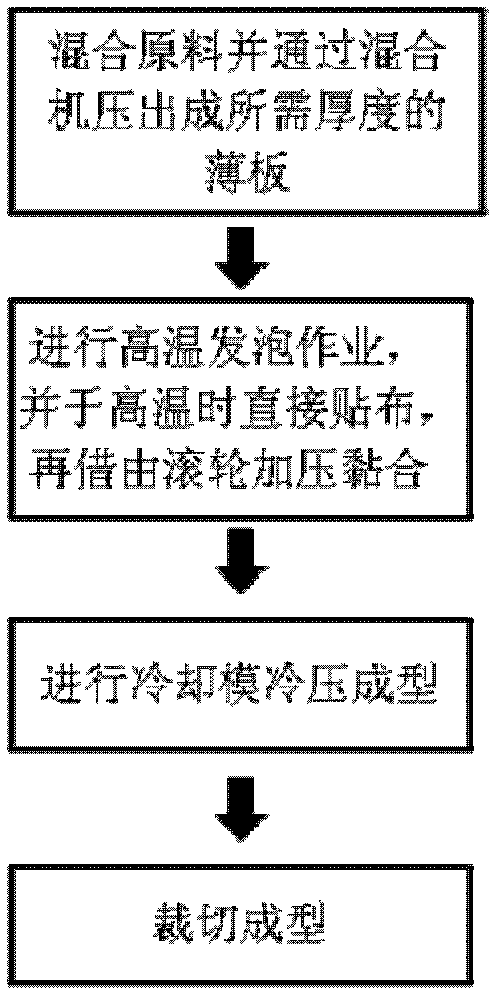

[0018] In order to obtain a more in-depth and specific understanding of the preparation method of the present invention, regarding the technical means, structural implementation and effect achievement of the present invention, I would like to give an example in conjunction with the drawings to further describe in detail:

[0019] like figure 2 As shown, the manufacturing method of the continuous operation of the present invention firstly adds the raw materials for making the insole into the mixer, and extrudes the thin plate with the required thickness of the insole through the mixer, and then the high temperature foaming operation is performed on the thin plate, and when the insole is produced When the foam sheet is in a high temperature state, the cloth is directly attached to the sheet, and the foam sheet and the cloth are forced to adhere to each other by the pressure of the roller, and then enter the cooling mold for cold pressing. The final insole contour can be cut and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com