Hot drying room for processing curing food

A technology for salted products and drying rooms, which is applied in food preservation, dry preservation of meat/fish, food science, etc. It can solve problems such as difficulty in stabilizing product quality, achieve uniform temperature and humidity distribution, avoid inconsistent drying degrees, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

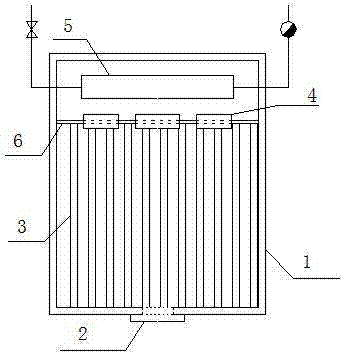

[0007] like figure 1 As shown, the present invention relates to a heat drying room for processing salted products, including a drying room 1, a door 2, a baffle plate 3, a rotating fan 4, a heat drain 5, and a temperature insulating plate 6.

[0008] The drying room 1 is a brick structure, and a baffle 3 is arranged on the parallel surface of the door 2 to divide the drying room into two parts. Device 5, baffle 3 The top of the outer drying room is equipped with a piece of equidistant heat insulation board 6, and the lower end of the baffle is not connected to the ground to ensure that the air outside the baffle and the air inside form heat convection.

[0009] When working, the heat of the steam is dissipated by the radiator 5, and then blown into the drying room outside the baffle by the rotating fan 4. After the heat is equalized by the temperature insulation board 6, it is evenly distributed on the surface of the pickled products, avoiding the drying of the pickled product...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com