Pipe connector

A connector and force technology, applied in the direction of sleeve/socket connection, pipe/pipe joint/pipe fitting, coupling, etc., to achieve the effect of fewer parts and simple parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

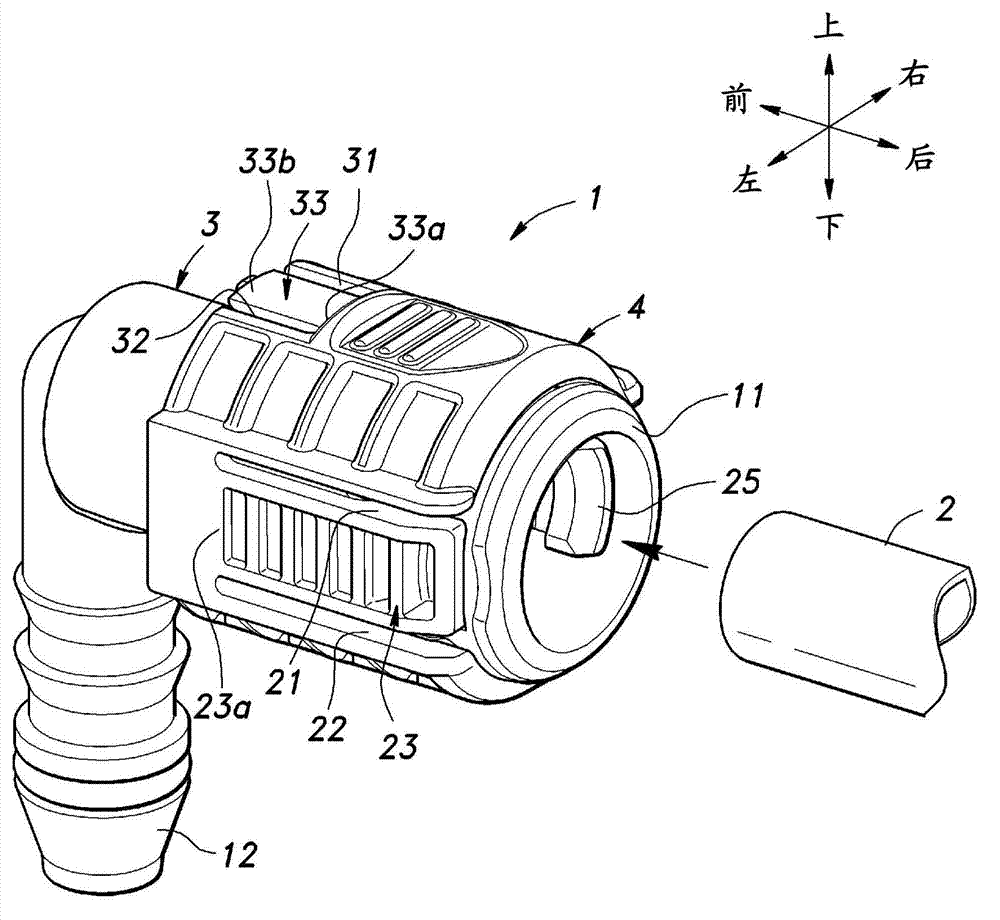

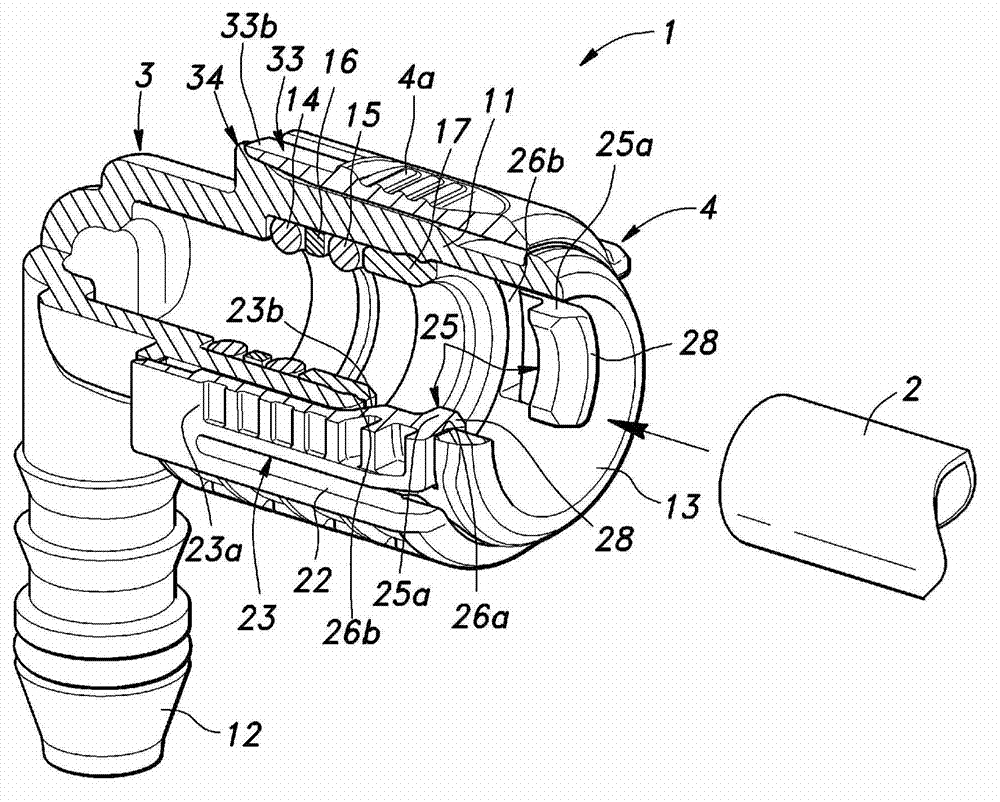

[0039] Below, refer to Figure 1 to Figure 8 , the pipe coupling connector according to the first embodiment of the present invention will be described. In the following, unless otherwise specified, the direction of the connector for pipe connection and the pipe is based on figure 1 It is determined by the direction indicated by the arrow in .

[0040] Such as figure 1 As shown, a tube connecting connector (hereinafter referred to simply as a connector) 1 is used to connect a tube 2 for fluid transport to a connection object (here, a hose for fluid transport not shown in the figure), and is mainly composed of The connector body 3 into which the tube 2 is inserted and removed is composed of a lock member 4 which is held movably in the front-rear direction by the connector body 3 and which fixes and releases the tube 2 in accordance with its forward-backward movement.

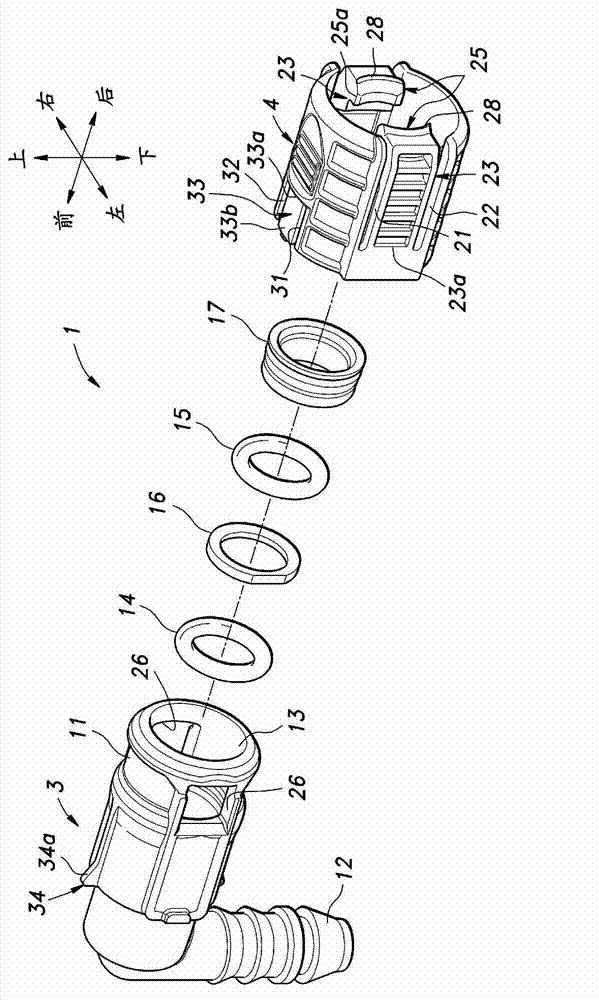

[0041] The connector main body 3 is made of synthetic resin material, and as figure 2 As shown, it includ...

no. 2 approach >

[0054] Next, refer to Figure 9 ~ Figure 13 , the pipe coupling connector of the second embodiment will be described. exist Figure 9 ~ Figure 13 In , the same symbols are assigned to the same components as those in the first embodiment. In addition, in the second embodiment, regarding the same matters as those in the first embodiment, a detailed description thereof will be omitted below except for matters mentioned in particular.

[0055] Such as Figure 9 As shown, the locking member 4 has a pair of curved arm-shaped elastic urging pieces 33 extending from the upper center to the left and right downwards, and a pair of elastic urging pieces 33 arranged between these elastic urging pieces 33 and extending downward from the upper center. Pin-shaped locking piece 23. Engagement claws 51 are respectively formed at free ends of the elastic biasing pieces 33 . In the second embodiment, the locking piece 23 has a structure that is hardly elastically deformable. In addition, t...

no. 3 approach >

[0063] Next, refer to Figure 14 ~ Figure 17 , the pipe connection connector of the third embodiment will be described. exist Figure 14 ~ Figure 17 In , the same symbols are assigned to the same components as those in the first embodiment. In addition, in the third embodiment, the same items as those in the first embodiment will not be described in detail below except for the items mentioned in particular.

[0064] Such as Figure 14 as well as Figure 15 As shown, the locking member 4 has a symmetrical shape up and down and left and right, and a pair of left and right elastic locking pieces 23 protrude from the annular portion 4b on the front end side toward the rear. As in the case of the first embodiment, the elastic locking piece 23 can be elastically deformed with the front base end portion 23a connected to the annular portion 4b as a fulcrum, so that the locking claw 25 can move in the radial direction (left-right direction) of the locking member 4. ) shift up. In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com