Aircraft fuselage made out with composite material and manufacturing processes

A manufacturing method and aircraft technology, which are applied in the field of aircraft fuselage and can solve problems such as difficulty in realizing the integration of truss beam heights and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

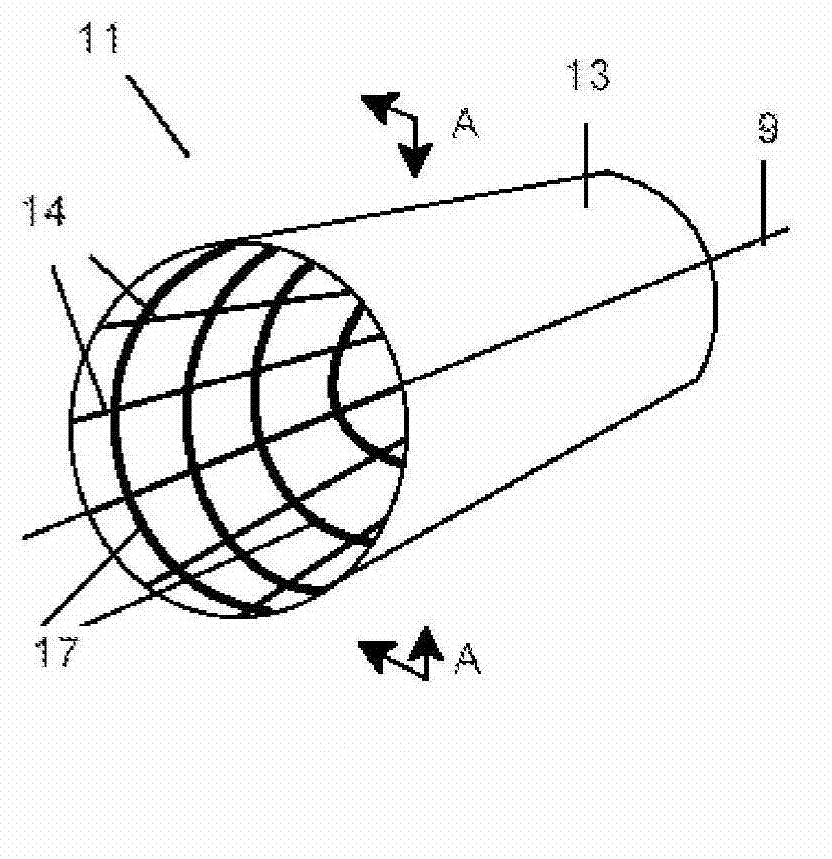

[0024] Circumferential orientation of fuselage panels

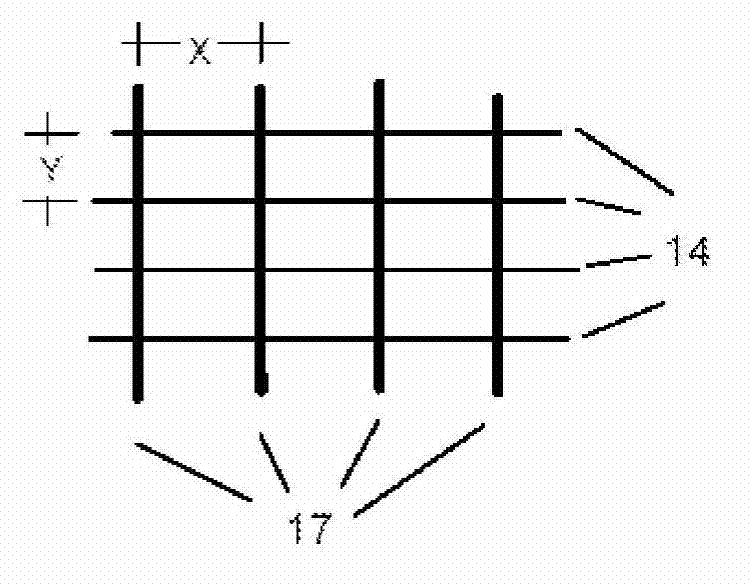

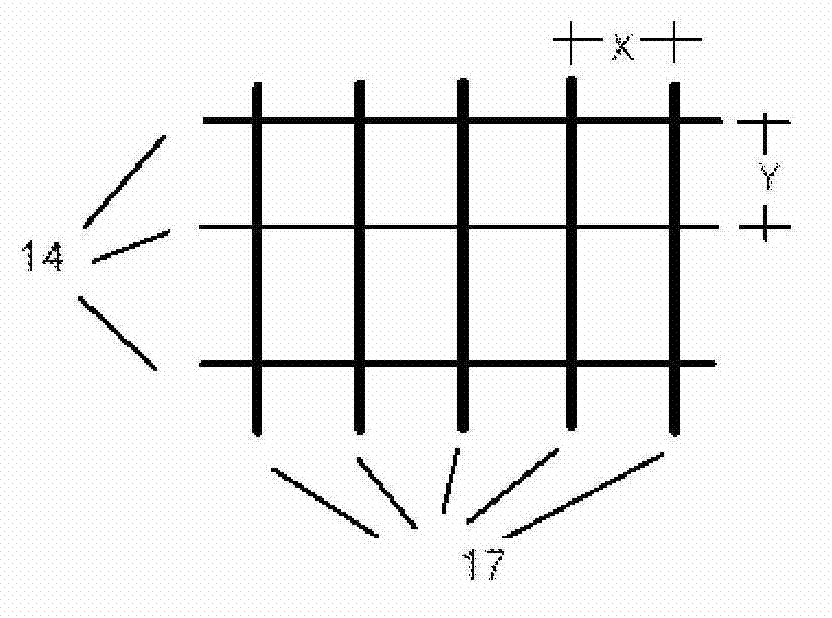

[0025] In contrast to the longitudinal orientation of the panels in known fuselages, the basic idea of the invention is to construct the fuselage section of the aircraft in such a way that its panels are oriented circumferentially. Among known airframes, such as Figure 1a As shown, the distance X between the frames 17 is greater than the distance Y between the girders 14, and in the fuselage section according to the present invention, as Figure 1b As shown, the distance X between the frames 17 is less than the distance Y between the girders 14 .

[0026] In known fuselages, a typical value for the X / Y ratio may be 2.5, whereas for the fuselage according to the invention it may be 0.6.

[0027] A first effect of the circumferential orientation of the plates is that the plates take advantage of the curvature of the fuselage to resist longitudinal loads, thereby delaying the onset of buckling. The increased postbucklin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com