Method for balancing electrolyte inlet flow of vanadium battery heaps and device thereof

A technology of balancing device and vanadium battery, which is applied in fuel cell additives, regenerative fuel cells, fuel cell grouping, etc., can solve problems such as inconsistencies in the liquid flow into the stack, achieve novel ideas, optimize working conditions, and prolong battery life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

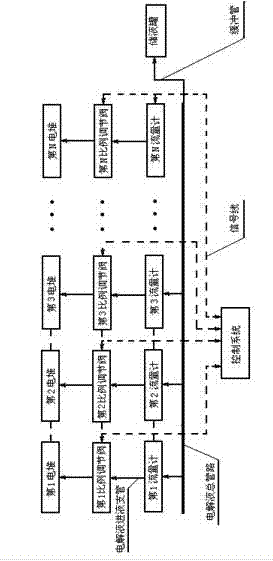

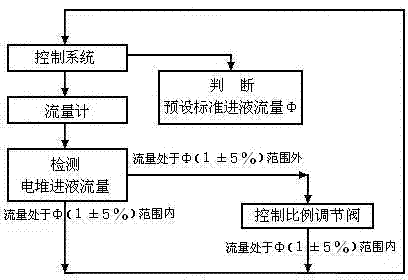

[0021] Such as figure 1 , figure 2 As shown, a method for equalizing the liquid flow rate of a vanadium battery stack proposed by the present invention is to use a control system to monitor the stack, and during the operation of the stack, the control system collects the flow rate of the flow meter used for the monitoring of the liquid flow rate into the stack. output signal; according to the output signal of the flowmeter used for the monitoring of the stack liquid inlet flow, the liquid inlet flow rate of the stack is obtained; and then it is judged whether the liquid inlet flow rate of the stack is within the limited range of the preset liquid inlet flow rate ; When the liquid inlet flow of the stack is greater than the upper limit of the preset liquid inlet flow or less than the lower limit of the preset liquid inlet flow, the control sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com