Grinding surface roughness predicting method and device under minimal lubrication of nanoparticle jet flow

A surface roughness and micro-lubrication technology, which is applied in the direction of electrical/magnetic roughness/irregularity measurement, electromagnetic measurement devices, etc., can solve the problem that the prediction model does not consider grinding fluid, and the prediction accuracy of the surface roughness model is difficult to meet production requirements. Actual needs, without considering the random distribution of abrasive grains on the surface of the grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

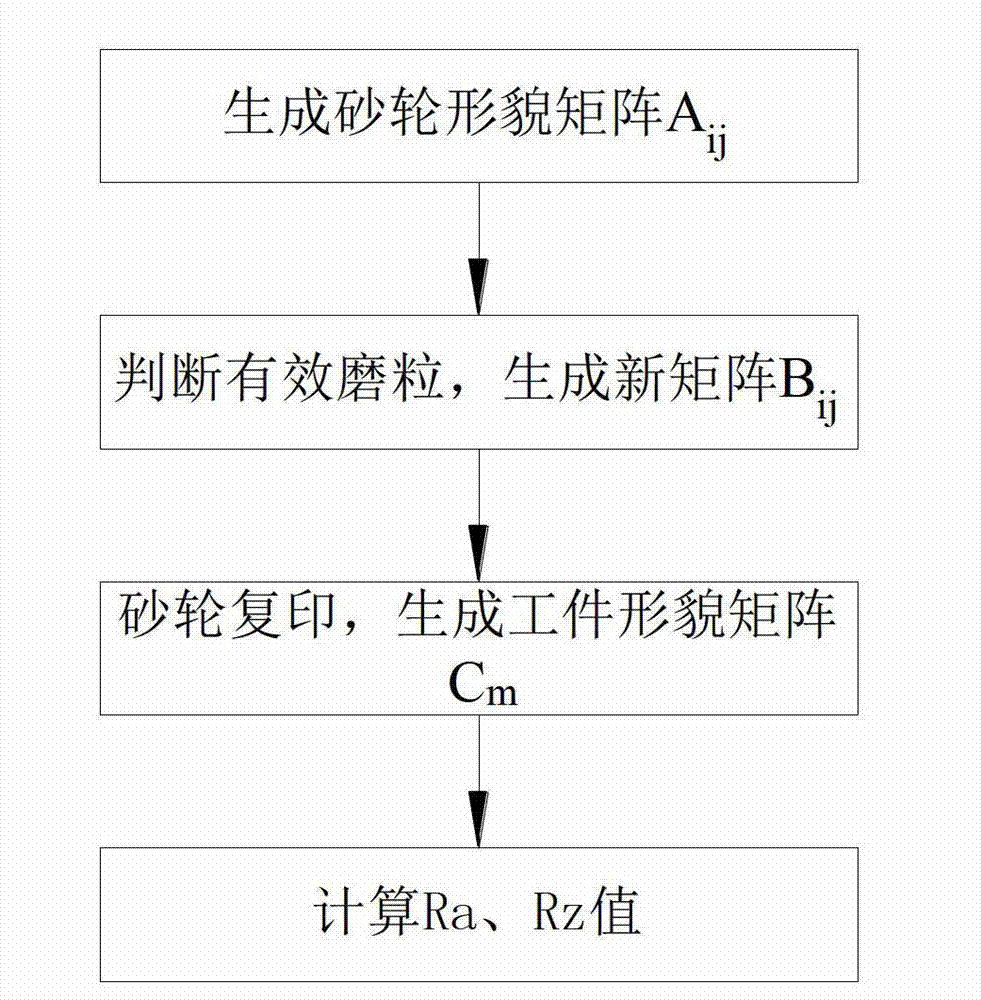

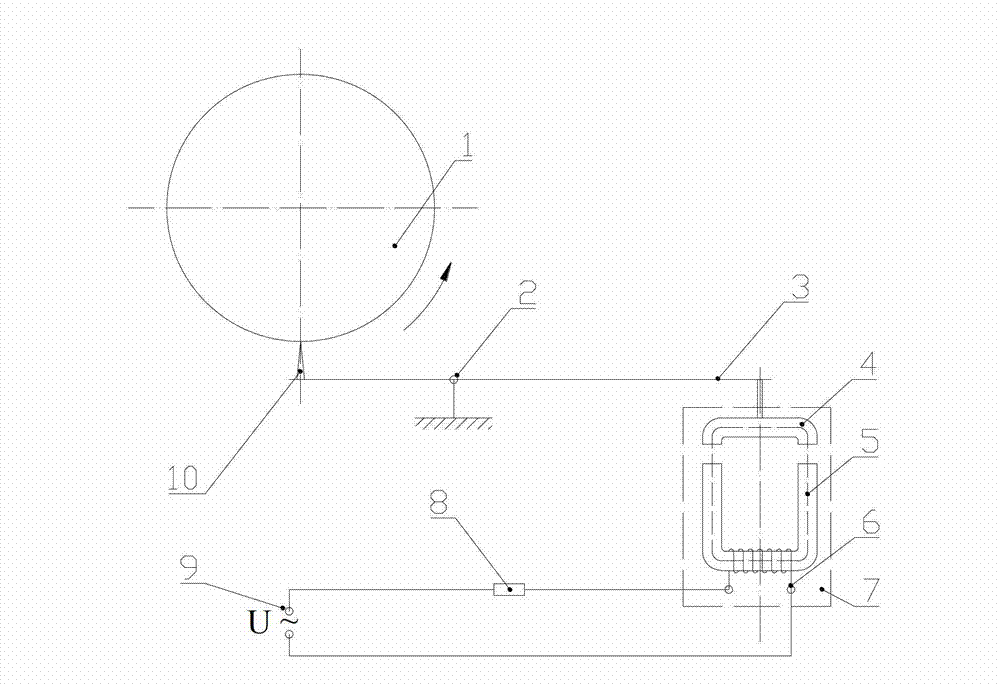

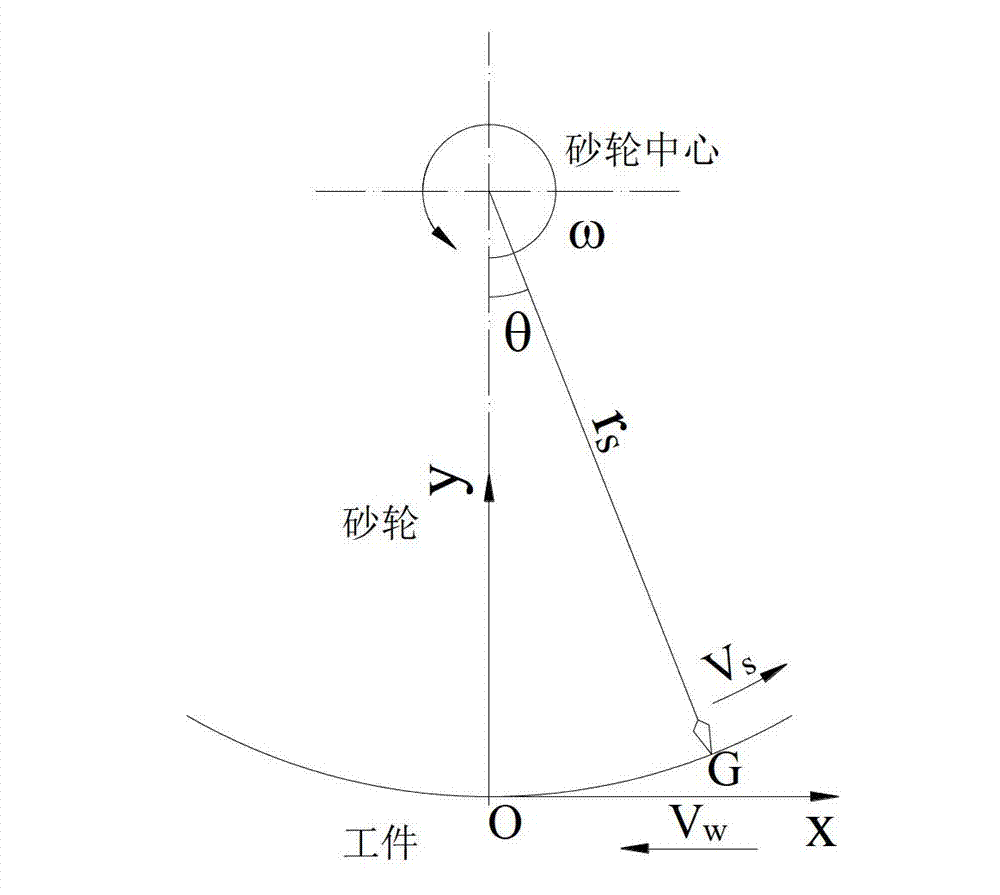

[0049] figure 1 Among them, a nano particle jet micro-lubrication grinding surface roughness prediction method, specifically, the surface topography curve of the grinding wheel is captured by the grinding wheel surface topography measuring device, and the horizontal and vertical coordinates of the peak point of the curve are the abrasive grains on the surface of the grinding wheel. Relative to the corner position and protrusion height, store the horizontal and vertical coordinates of the peak point of the curve as a matrix A ij , according to the effective wear particle judgment condition, from the morphology matrix A ij Select the peak points that meet the conditions, store the corresponding horizontal and vertical coordinates to generate a new matrix B ij , and then according to the creation mechanism of the surface topography of the grinding workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com