Composite alternative acid dissolving method of hyposmosis oil layer

A low-permeability, oil-reservoir technology, applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems of poor compatibility and achieve the effect of improving oil production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above and other objects, features and advantages of the present invention more comprehensible, preferred embodiments are listed below and described in detail in conjunction with the accompanying drawings.

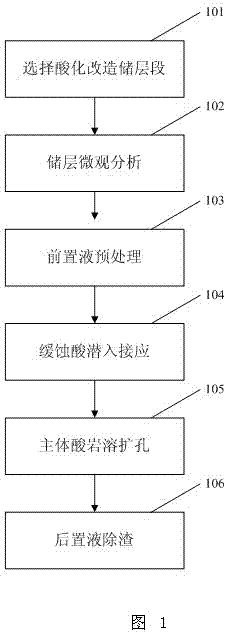

[0028] Such as figure 1 as shown, figure 1 It is a flow chart of the low-permeability oil layer composite alternate acid solution method of the present invention. In step 101, targeted sampling is carried out, and a section of the reservoir for acidification and stimulation is selected. The principles of layer selection mainly include two aspects: first, the target interval has relatively good oil content, and the oil content level should be above the oil spot level. In one embodiment, oil immersion and oil spots were found in the 2918.1m-2922.0m section of the well in geological logging, borehole wall coring, and drilling coring; secondly, the distance between the target interval and the upper and lower aquifers is relatively large, In one em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com