Pure light steel joist ceiling

A light steel keel and suspended ceiling technology, which is applied to ceilings, building components, buildings, etc., can solve the problems of wood base cracking, insects, and easy corrosion, and achieve the effect of controlling the construction period and reducing the formaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

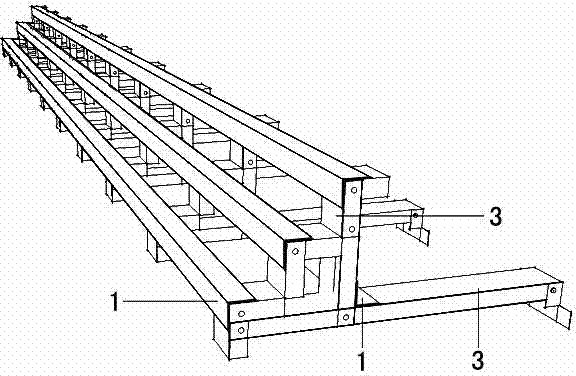

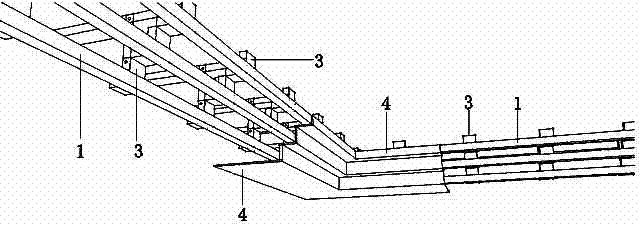

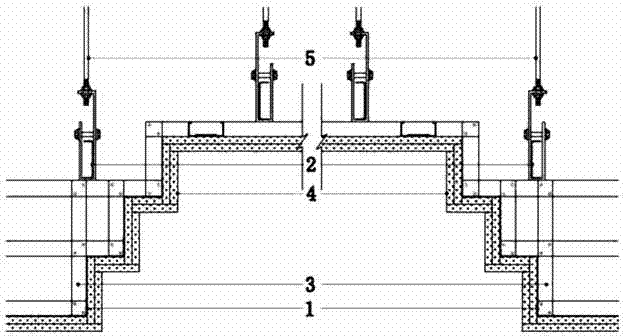

[0020] Example: such as figure 2 , image 3 As shown, a pure light steel keel ceiling, which includes a step-down modeling base, gypsum board and gypsum lines 4, a main keel 2, a step-down modeling base includes an L-shaped side keel 1, an auxiliary keel 3, and the auxiliary keel 3 constitutes a step-down For the skeleton support of the modeling base, the distance between each support unit of the skeleton support composed of auxiliary keels 3 is 400mm; The L-shaped side keel 1 and the auxiliary keel 3 are fixed by rivets. The surface layer of the downgraded modeling base is covered with gypsum boards and gypsum lines 4 to form an integral ceiling; the auxiliary keel 3 is connected with the main keel 2 . The main keel 2 is fixed to the roof by a screw mandrel 5 .

[0021] The following are the construction steps of this embodiment.

[0022] 1. According to the top surface modeling nodes, use auxiliary keels 3 to make the support of the lowering and modeling skeletons. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com