Tamping device

An equipment and ramming technology, applied in soil protection, sheet pile walls, buildings, etc., can solve the problems of limited use time of ramming equipment, limited heat dissipation of passive heat sinks, etc., to achieve flow characteristics, high air velocity, improved cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

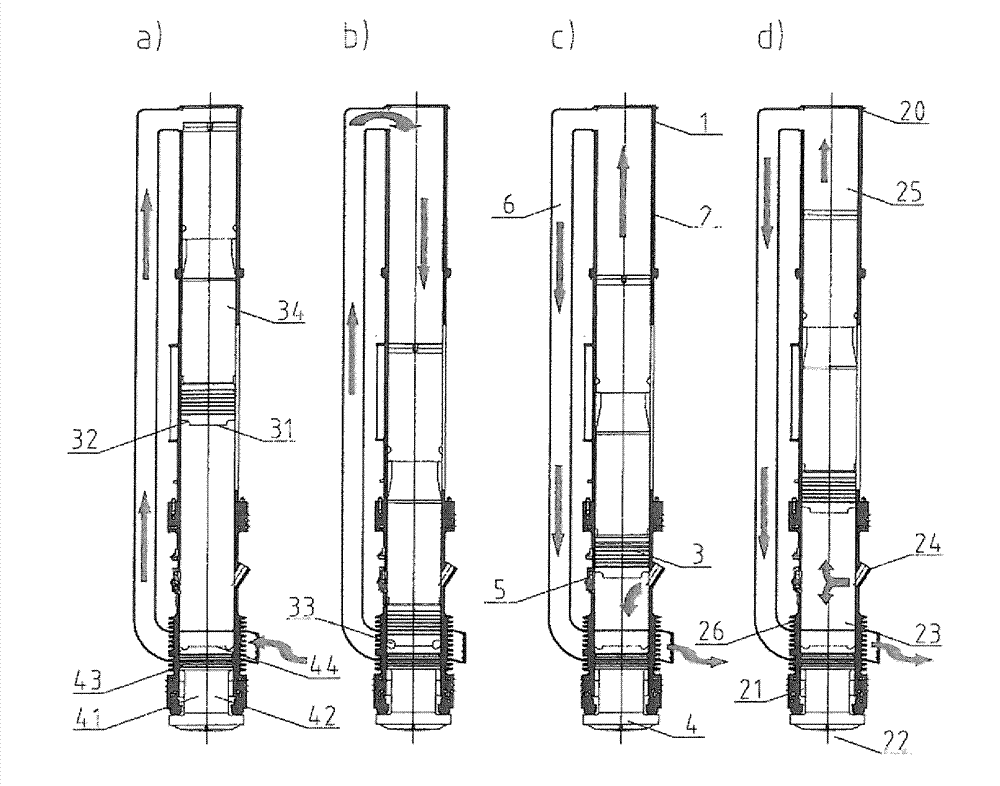

[0012] The rammer device chosen as exemplary embodiment is designed as a diesel rammer 1 . The diesel rammer 1 has a cylinder 2 which is open on one side and which can actually have a length of 5 to 10 meters and a diameter of 0.5 to 1 meter. The cylinder 2 is closed on its upper side by a cover plate 20 . A piston 3 is displaceably arranged in the cylinder 2 . A tamper block 4 coaxial therewith engages displaceably in the open lower end of the cylinder 2 . Arranged on the open lower end 22 of the cylinder 2 is an annular bearing unit 21 , in which a central shaft section 41 of the tamper block 4 is guided, said central shaft section having an angle relative to the cylinder 2 . Outer diameter with reduced inner diameter.

[0013] A striking plate 42 located below the cylinder 2 is integrally formed onto the lower end of the shaft section 41 , whose outwardly aligned, bottom-protruding border surface is in contact with the pile to be pressed in during operation, such as a sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com