Vibrating mechanism for vibrator feeder

A vibrating feeder and vibrating mechanism technology, applied in vibrating conveyors, conveyors, transportation and packaging, etc., can solve problems such as the inability to meet the use requirements of vibrating feeders, and achieve good vibration effect, free vibration and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further elaborate the present invention in combination with specific diagrams and specific examples, but it is not intended to limit the protection scope of the present invention.

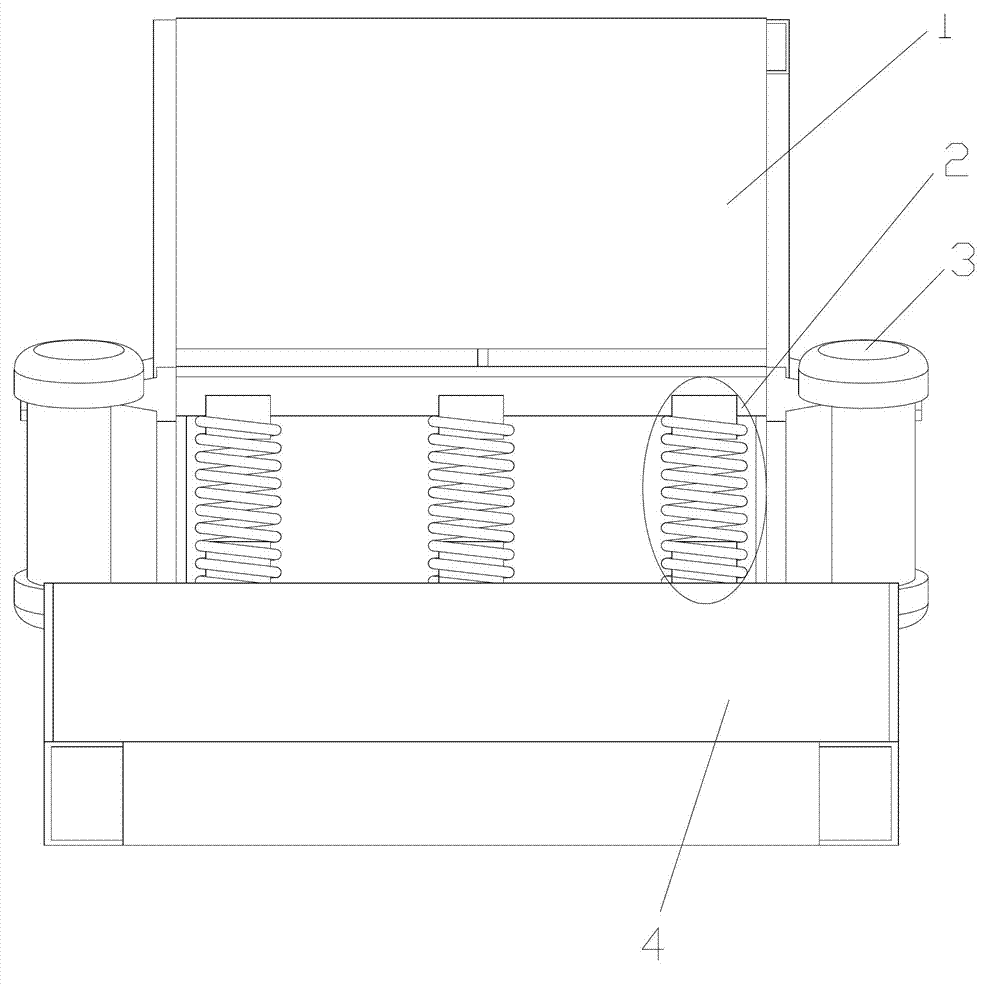

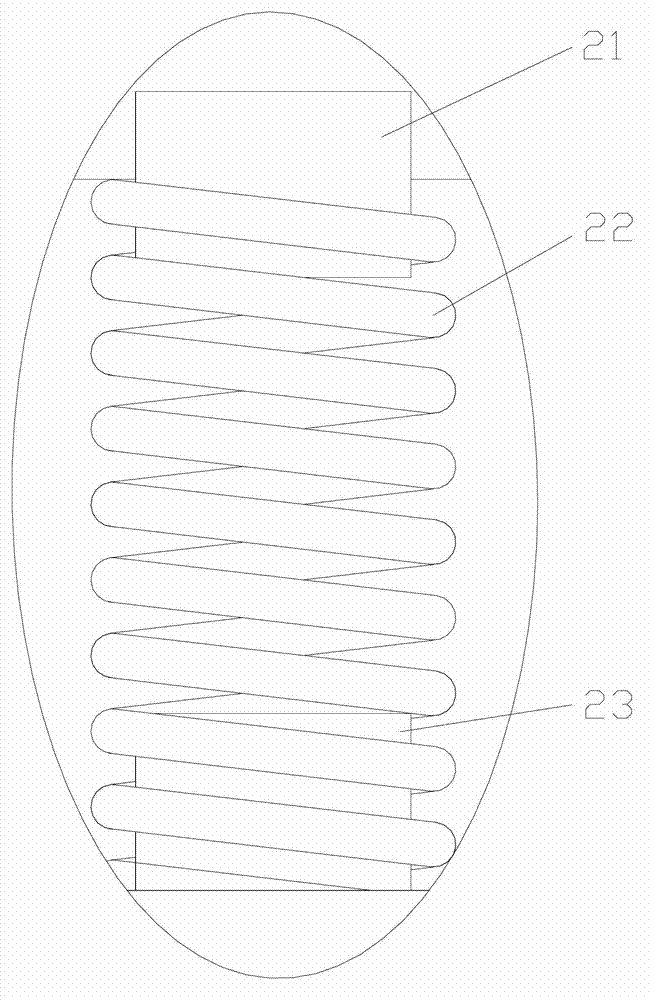

[0014] Please refer to figure 1 , figure 2 , a vibrating mechanism of a vibrating feeder, comprising a vibrating box 1 with a vibrating motor 3 fixed on the side, the lower end of the vibrating box 1 is supported on a base 4 by a vibrating mechanism 2, the vibrating mechanism 2 includes a vibrating spring 22, the vibrating spring 22 upper ends insert spring upper fixed rod 21 downwards, vibration spring 22 lower ends upwards insert spring lower fixed rod 23, spring upper fixed rod 21 is fixed on vibration box 1 bottom, spring lower fixed rod 23 is fixed on the base 4.

[0015] Vibration spring 22 upper and lower two ends are respectively fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com